35Ww350 Non-Oriented Silicon Steel

The silicon content of the alloy is 1.5% to 3.0%, or the sum of silicon and aluminum content is 1.8% to 4.0%. The product is usually cold-rolled sheet or strip with nominal thicknesses of 0.35 and 0.5mm, mainly used for manufacturing electric motors and generators. Silicon steel, commonly known as silicon steel sheet or silicon steel sheet, is an indispensable low-carbon soft magnetic alloy of silicon iron in the power, electronics, and military industries. It is also the most widely produced metal functional material, accounting for about 1% of the world's steel production.

It is a silicon iron alloy containing 0.8% -4.8% silicon, which is hot and cold rolled into thin silicon steel sheets with a thickness of less than 1mm. Adding silicon can increase the electrical resistivity and maximum magnetic permeability of iron, reduce coercivity, iron core loss (iron loss), and magnetic aging, mainly used as iron cores for various motors, generators, and transformers.

Our company's products have obtained ISO9001 certification, ensuring product quality

35Ww350 Non-Oriented Silicon Steel - Premium Electrical Steel Solution

When you need reliable magnetic materials for your electrical equipment manufacturing, 35Ww350 non-oriented silicon steel delivers exceptional performance. This premium silicon iron alloy features very low carbon content with grains that exhibit irregular orientation distribution throughout the deformed and annealed steel plate. Our material contains silicon content between 1.5% to 3.0%, making it perfect for your motor and generator applications.

What Makes Our Silicon Steel Special

Our silicon steel sheets offer superior electrical properties that set them apart in the market. The addition of silicon increases electrical resistivity and maximum magnetic permeability while reducing coercivity and iron core losses. This means your equipment operates more efficiently with less energy waste.

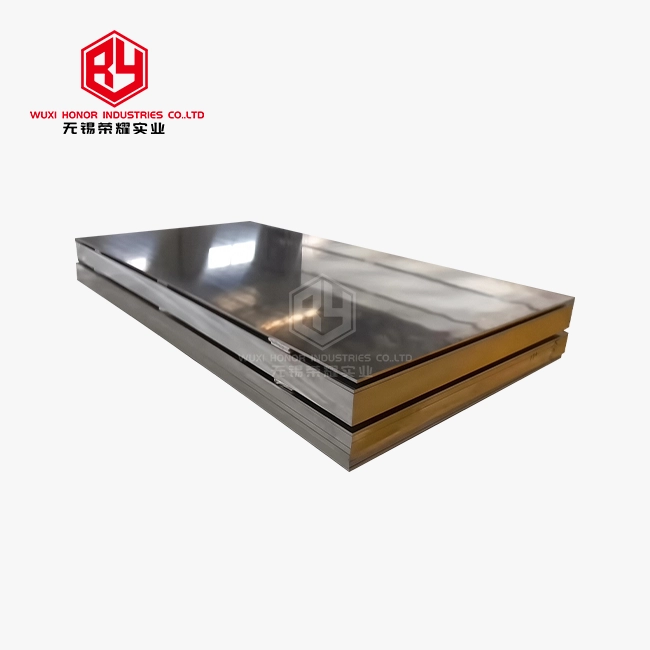

You'll appreciate the consistent thickness options we provide. Our 35Ww350 non-oriented silicon steel comes in nominal thicknesses of 0.35mm and 0.5mm, cold-rolled to precise specifications. These dimensions ensure optimal performance in your electrical applications.

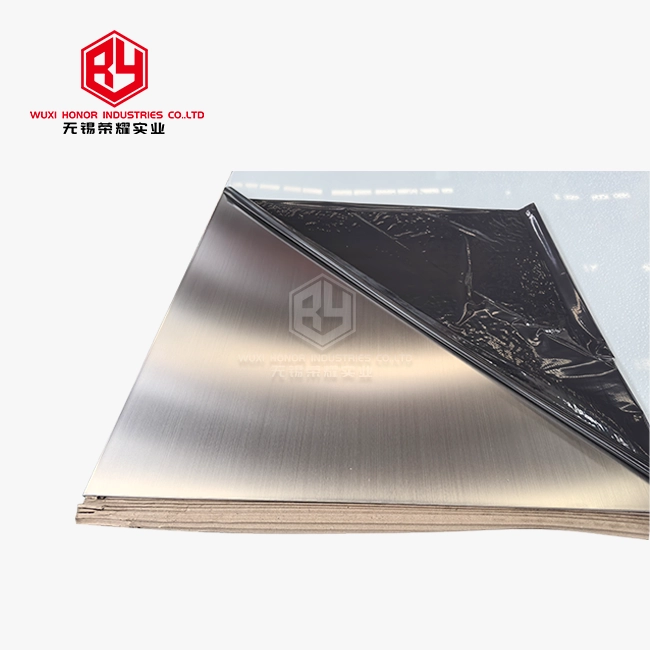

The material features excellent surface quality with smooth, flat characteristics. This superior finish translates to better machinability when you're stamping cores for motors or transformers. You'll experience fewer production issues and reduced material waste.

Key Performance Benefits

Low Iron Loss, High Efficiency: Our steel maintains guaranteed iron loss of just 3.5 W/kg under 50 Hz alternating magnetic field conditions at 1.5 Tesla magnetic flux density. This low energy loss directly improves your equipment's operational efficiency.

Isotropic Magnetic Properties: The magnetic characteristics remain uniform across all directions. This isotropy makes our material ideal for rotating motor applications where multi-directional magnetic circuits are essential.

Superior Workability: The uniform thickness and smooth surface quality ensure excellent dimensional accuracy during stamping operations. You'll notice reduced burr formation and crack tendency, leading to higher production yields.

Certificate

Applications and Industries

This versatile magnetic material serves multiple industries effectively. Manufacturing sectors rely on our silicon steel for electric motor production, from small appliances to industrial machinery. Power generation companies use it in generator cores where consistent magnetic properties are crucial.

Transformer manufacturers appreciate the material's low core losses, which translate to energy-efficient power distribution systems. The automotive industry utilizes our 35Ww350 non-oriented silicon steel in electric vehicle motors and charging infrastructure components.

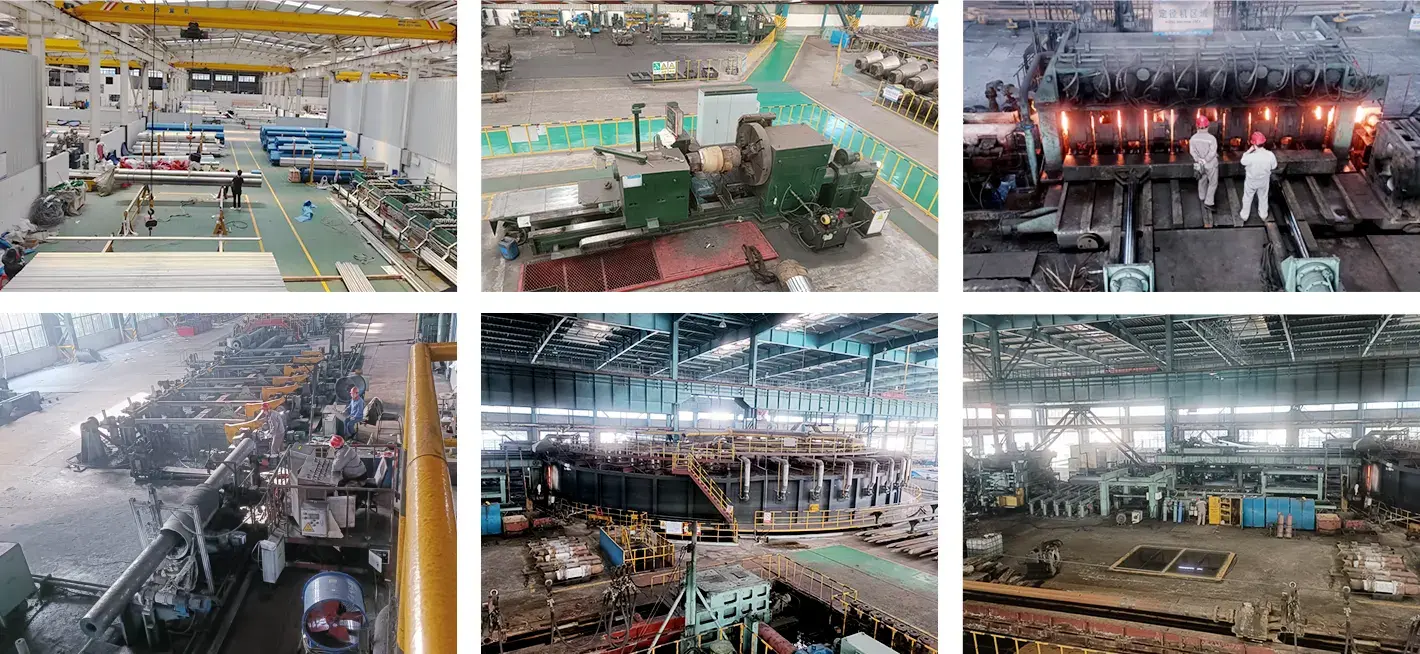

Why Choose WUXI HONOR INDUSTRIES

We bring over ten years of specialized experience in metal materials foreign trade. Our global supply network spans more than 100 countries, ensuring reliable delivery wherever your operations are located.

Our comprehensive quality control processes guarantee product traceability and consistency. Every batch meets international standards, backed by our ISO9001 certification. We understand that your production schedules are critical, so we maintain stable inventory levels and efficient logistics.

You'll work with a team that speaks your language and understands your regional requirements. Our multilingual communication capabilities and international service experience ensure smooth transactions from inquiry to delivery.

Technical Specifications

The silicon content in our alloy ranges from 1.5% to 3.0%, with the total silicon and aluminum content between 1.8% to 4.0%. This composition delivers optimal magnetic properties while maintaining good mechanical characteristics for processing.

Available in cold-rolled sheet or strip form, our material offers flexibility for various manufacturing processes. The consistent thickness tolerance ensures predictable performance in your applications.

Exhibition

Getting Started

Ready to enhance your electrical equipment performance? Our 35Ww350 non-oriented silicon steel provides the magnetic properties and processing advantages your manufacturing needs. Contact our experienced team at admin@rongyaopipe.com to discuss your specific requirements and receive detailed quotations for your next project.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!