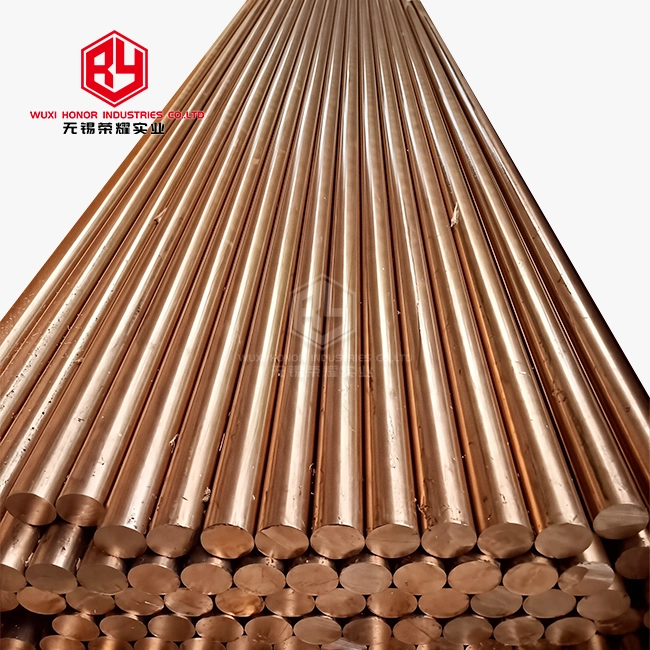

T2 Copper Busbar

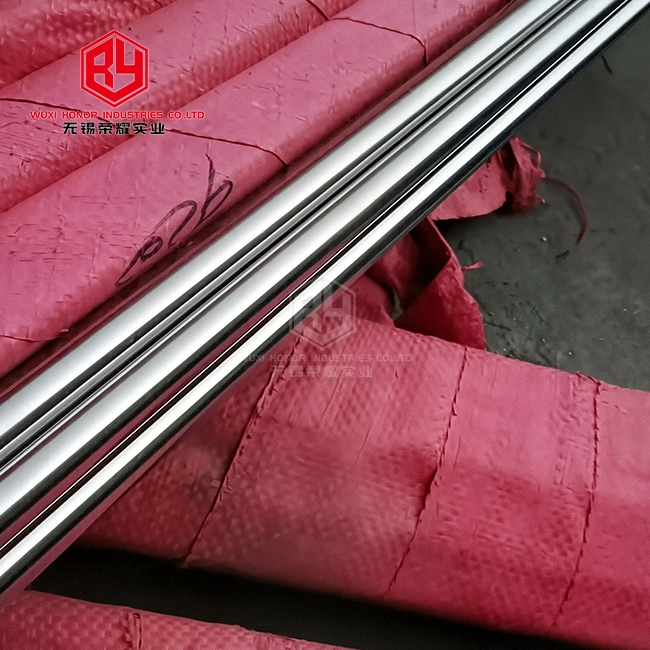

Its laser cutting processing characteristics support the production of precision parts. In the fields of conductivity, welding, and brazing. Corresponding to international grades such as SE Cu from Germany and C11000 from the United States. Export products must comply with ASTM B152/B152M

Our company's products have obtained ISO9001 certification, ensuring product quality

T2 Copper Busbar - Premium Electrical Conductor for Power Systems

What is T2 Copper Busbar and Why Choose It?

Looking for dependable electrical conductors for your control frameworks? T2 copper busbar stands out as the head choice for mechanical applications. This high-grade copper fabric meets GB/T5231-2001 benchmarks and conveys remarkable electrical conductivity with copper substance ≥99.90%. Whether you're working on generator windings, control transmission frameworks, or electrical dispersion boards, it gives the unwavering quality and execution your ventures request. Its predominant virtue guarantees negligible vitality misfortune and steady current carrying capacity for basic electrical applications.

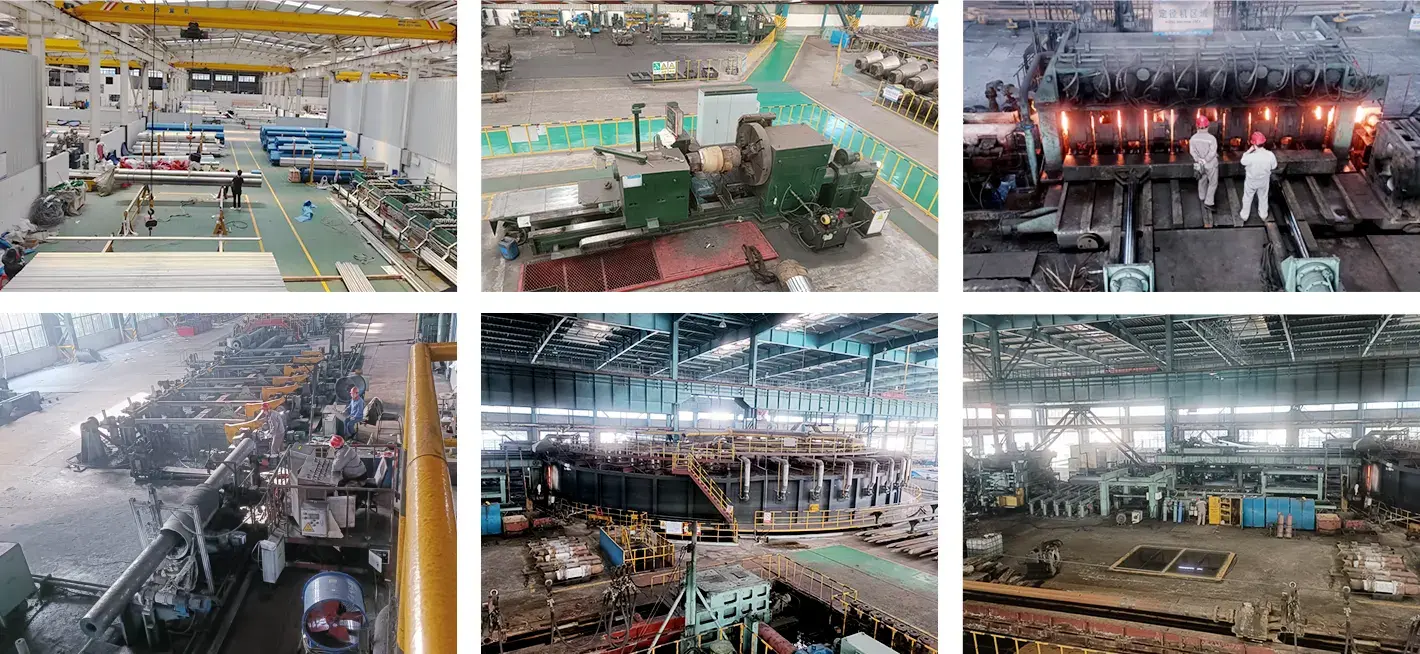

At WUXI HONOR Businesses CO.LTD, we get it your require for reliable quality and reliable supply. With over ten a long time of involvement serving clients over 100+ nations, we've built our notoriety on conveying premium copper busbars that meet universal standards.

Outstanding Electrical Performance

Your electrical frameworks merit components that provide reliable execution. Immaculate copper busbars offer conductivity levels that aluminum options essentially cannot coordinate. With copper virtue surpassing 99.90%, these conductors minimize resistance and diminish vitality misfortunes in your control dispersion networks.

The amazing current-carrying capacity makes them idealize for high-voltage applications. You'll discover these busbars keep up steady execution indeed beneath requesting electrical loads. This unwavering quality interprets to diminished downtime and progressed framework proficiency for your operations.

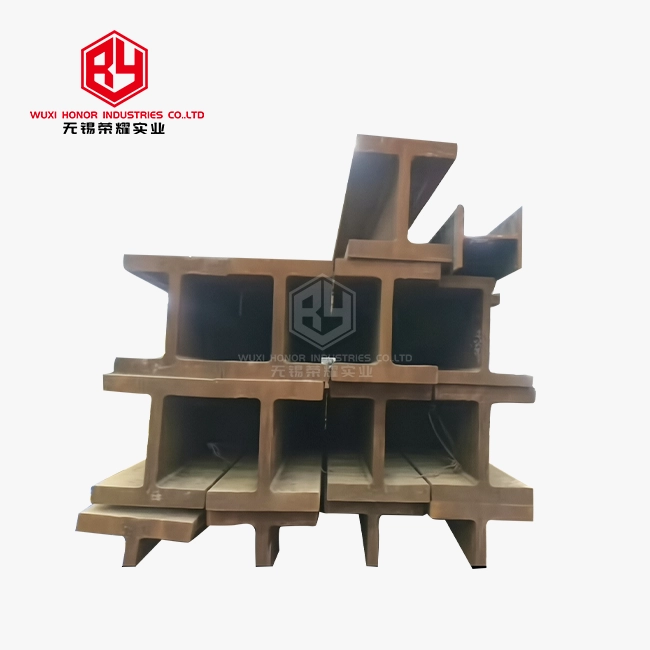

Versatile Applications Across Industries

T2 copper busbar conductor bars serve different businesses with surprising flexibility. Control era offices depend on them for generator windings and transformer associations. Mechanical fabricating plants utilize them in engine control centers and switchgear applications.

Chemical handling offices advantage from their erosion resistance in unforgiving situations. Warm exchanger producers appreciate their warm conductivity properties. The material's laser cutting compatibility empowers exactness component fabricating for specialized applications.

Construction ventures regularly indicate these conductors for building electrical frameworks. Their strength guarantees long-term execution in commercial and mechanical installations.

Superior Processing and Installation Benefits

Working with copper busbars offers noteworthy points of interest amid creation and establishment. The material's fabulous versatility permits for simple shearing, bowing, and penetrating operations. You can customize measurements and shapes to meet particular extend necessities without compromising auxiliary integrity.

Welding and brazing operations continue easily with appropriate strategies. The prepared components keep up tall dimensional exactness, guaranteeing tight associations and dependable joints. Establishment gets to be clear, indeed in complex electrical formats with space constraints.

These preparing characteristics diminish labor costs and venture timelines. Your establishment groups will appreciate the material's workability and reliable quality.

International Standards and Quality Compliance

Our copper busbars correspond to recognized international grades including Germany's SE Cu and America's C11000 standards. Export products comply with ASTM B152/B152M specifications, ensuring global compatibility for your projects.

ISO9001 certification guarantees consistent quality control throughout our manufacturing processes. This certification reflects our commitment to meeting your quality expectations and international standards.

Quality traceability systems track materials from source to delivery. You receive detailed documentation supporting your project compliance requirements.

Why Choose WUXI HONOR INDUSTRIES

Our decade-long presence in metal materials trading brings valuable experience to your projects. We've developed efficient supply chains connecting you with premium copper products while maintaining competitive pricing.

Serving customers worldwide has taught us the importance of reliable delivery schedules. Our global logistics network ensures your materials arrive when and where you need them. We understand the critical nature of electrical components in your operations.

Custom solutions address unique project specifications. Whether you need specific dimensions, quantities, or delivery schedules, our team works to meet your requirements. Flexible order processing accommodates projects of various scales.

Technical Specifications and Customization

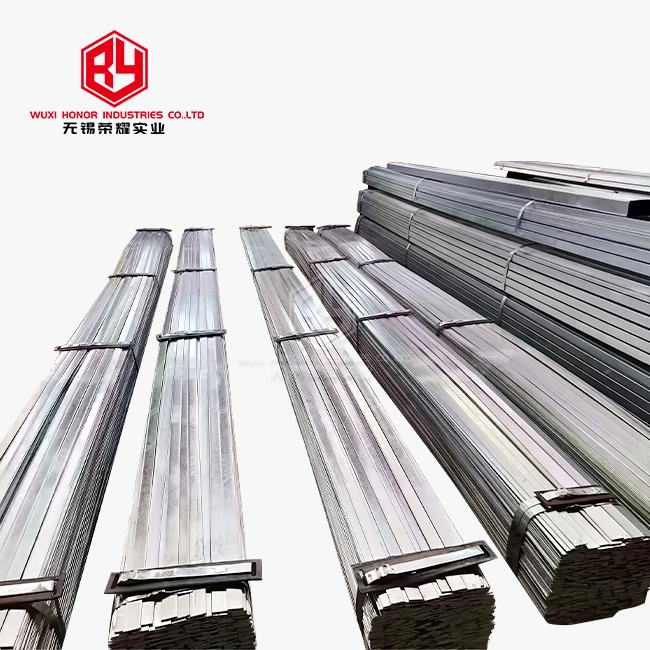

Standard copper busbar dimensions accommodate most electrical applications. However, custom sizing ensures optimal fit for your specific installations. Our processing capabilities include precision cutting, forming, and finishing operations.

Surface treatments enhance corrosion resistance and improve connection reliability. Various coating options protect against environmental factors in challenging installations. These treatments extend service life and maintain electrical performance over time.

Exhibition

Contact Us for Your Copper Busbar Needs

Ready to source premium T2 copper busbar for your next project? Our experienced team stands ready to discuss your specific requirements and provide competitive quotations. Contact us at admin@rongyaopipe.com to start your order process today.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!

Seamless Steel Pipe.webp)