310S Stainless Steel Round Steel

The softening temperature starts at 800 ℃ and can be improved by solution treatment at 1030 ℃~1180 ℃. Mainly used in the manufacturing of high-temperature equipment components such as electric furnace tubes, heat treatment furnaces, combustion chambers, and heat exchangers, suitable for high-temperature environments such as petrochemicals, energy, and coke oven riser heat exchangers.

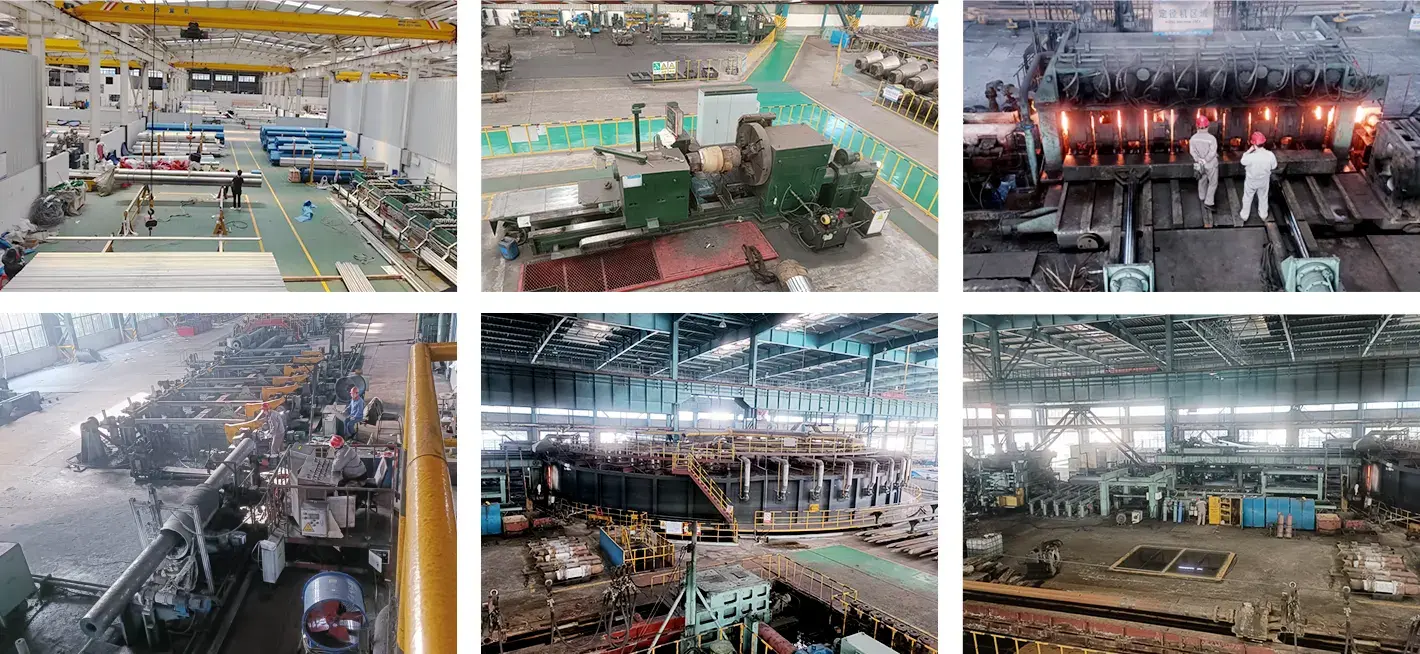

The seamless pipe production process includes hot rolling perforation, cold rolling processing, and acid washing, while the welded pipe adopts a combined process of strip welding and solution heat treatment.

Our company's products have obtained ISO9001 certification, ensuring product quality

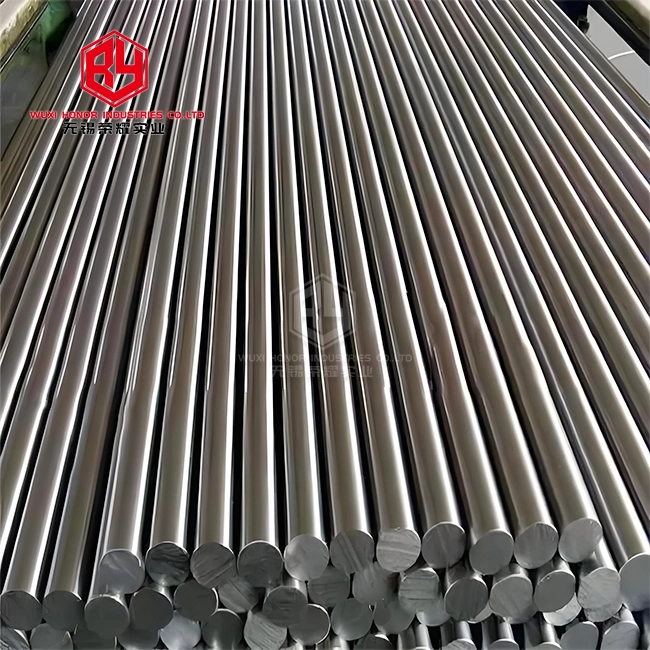

310S Stainless Steel Round Steel - Premium High-Temperature Solution

When you're looking for remarkable warm resistance and erosion security, 310S stainless steel round steel stands out as the extreme choice for requesting mechanical applications. This austenitic chromium-nickel amalgam combines momentous solidness with extraordinary execution characteristics. Our 310S stainless steel circular bars convey unmatched unwavering quality in extraordinary conditions, making them idealize for your high-temperature ventures. With over ten a long time of industry mastery, we get it precisely what you require for success.

Exceptional Material Properties

Our 310S circular steel highlights an noteworthy chemical composition that sets it separated from standard grades. You'll discover 24-26% chromium and 19-22% nickel substance, making prevalent oxidation resistance. The fabric keeps up auxiliary judgment at persistent working temperatures up to 1150°C, with top execution coming to 1200°C.

The malleable quality surpasses 520MPa whereas keeping up amazing ductility. You can tally on reliable abdicate quality over 205MPa and prolongation rates of 40% or higher. These properties guarantee your components perform dependably beneath stretch and warm cycling.

Superior High-Temperature Performance

Your applications request materials that won't come up short beneath extraordinary conditions. Our 310S stainless steel round steel bars exceed expectations in situations where standard materials would fall apart quickly. The tall chromium and nickel substance makes a defensive oxide layer that anticipates scaling and oxidation.

Even amid warm stun conditions, the fabric keeps up its mechanical properties. You won't encounter the twisting or splitting common with lower-grade amalgams. This steadiness interprets to decreased support costs and expanded hardware life.

Certificate

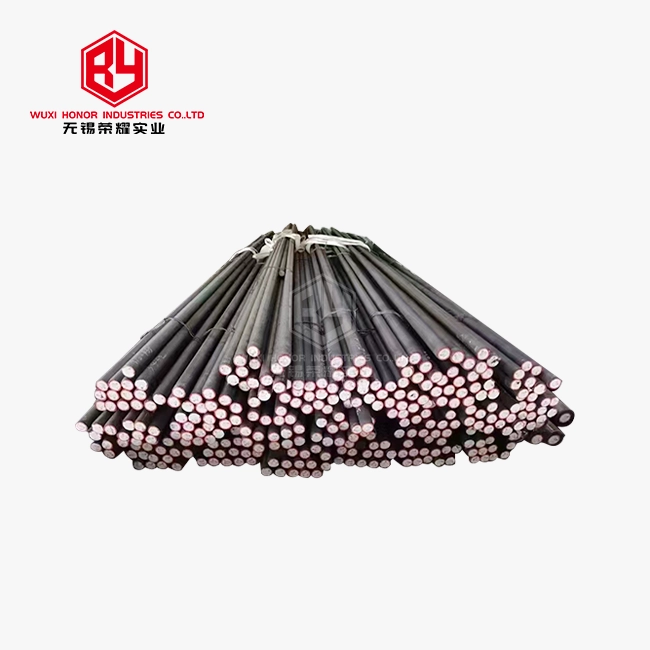

Versatile Industrial Applications

Manufacturing experts select our circular bars for differing high-temperature applications. Warm treatment heaters advantage from the material's warm soundness and oxidation resistance. Petrochemical preparing hardware depends on its erosion resistance against forceful chemicals.

Electric heater components made from our steel provide reliable execution over expanded working periods. Combustion chamber applications appreciate the material's capacity to withstand quick temperature changes without corruption.

Quality Manufacturing Process

We employ advanced production techniques to ensure consistent quality throughout every bar. Our hot rolling and solution treatment processes optimize the microstructure for maximum performance. Strict temperature control during processing eliminates internal stresses that could compromise service life.

Each production batch undergoes comprehensive testing to verify chemical composition and mechanical properties. Our quality control system ensures you receive materials that meet or exceed international standards.

Global Supply Reliability

With distribution networks spanning over 100 countries, we understand your supply chain challenges. Our established relationships with premium steel mills guarantee consistent material availability. You can rely on timely delivery regardless of your project location.

Our experienced team handles complex logistics requirements efficiently. From documentation to customs clearance, we manage every detail to ensure smooth international delivery. This comprehensive service approach has earned trust from clients worldwide.

Exhibition

Technical Support and Customization

Your specific requirements deserve personalized attention. Our technical team provides detailed specifications and application guidance to optimize your material selection. We offer various diameter options and length configurations to match your manufacturing needs.

Custom heat treatment options are available to achieve specific hardness levels or microstructural characteristics. Our metallurgical expertise ensures you receive materials tailored to your exact performance requirements.

For reliable 310S stainless steel round steel that exceeds your performance expectations, contact our experienced team at admin@rongyaopipe.com today to discuss your specific requirements and receive personalized recommendations.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!

Seamless Steel Pipe.webp)