How to weld stainless steel plate safely?

Welding stainless steel plate requires precision, skill, and most importantly, a strong focus on safety. Whether you're a seasoned professional or a beginner in the welding industry, understanding the proper techniques and safety measures is crucial. This comprehensive guide will walk you through the essential steps to ensure safe and effective welding of stainless steel plates.

Essential Personal Protective Equipment (PPE) for Welding

Before you begin welding stainless steel plates, it's crucial to equip yourself with the right personal protective equipment (PPE). This gear not only ensures your safety but also enhances your comfort during the welding process.

Welding Helmet

A high-quality welding helmet is essential to safeguard your eyes and face from harmful radiation and flying sparks. Look for an auto-darkening helmet with adjustable shade settings that respond to the intensity of the welding arc. This allows for optimal visibility while automatically adjusting the lens to protect your eyes from the intense light produced during welding.

Fire-Resistant Clothing

Wearing fire-resistant clothing, such as flame-resistant coveralls or a welding jacket, is crucial to protect your skin from sparks, hot metal spatter, and molten slag. Ensure the clothing is made from durable materials such as cotton or leather, and avoid synthetic fabrics that could melt, leading to severe burns during the welding process.

Welding Gloves

Invest in high-quality, heavy-duty leather welding gloves that are specifically designed to provide protection against extreme heat, sparks, and sharp metal edges. These gloves will not only safeguard your hands but also enhance your grip and dexterity, making it easier to handle the materials while welding.

Safety Glasses

While your welding helmet provides primary eye protection, it's always a good idea to wear additional safety glasses underneath, especially when chipping slag or grinding. Safety glasses offer extra protection against debris, metal fragments, or any unexpected sparks that may escape the helmet.

Respiratory Protection

Welding produces hazardous fumes and gases, particularly when working with stainless steel. Use a proper respirator or welding fume extraction system to protect your lungs from these toxic substances. A respirator with a P100 filter will help reduce your exposure to harmful fumes, ensuring you maintain good respiratory health while welding.

Preparing Your Workspace and the Stainless Steel Plate

A clean and organized workspace is essential for safe and effective welding of stainless steel plates. Proper preparation can significantly impact the quality of your welds and minimize potential hazards.

Workspace Setup

Ensure your welding area is well-ventilated to disperse fumes and gases. Remove any flammable materials from the vicinity and have a fire extinguisher readily available.

Cleaning the Stainless Steel Plate

Thoroughly clean the stainless steel plate to remove any dirt, oil, or contaminants that could affect weld quality. Use a stainless steel wire brush or acetone to clean the surface.

Securing the Plate

Use clamps or a welding table to secure the stainless steel plate firmly in place. This prevents movement during welding and ensures more precise welds.

Preheating

Depending on the thickness of the stainless steel plate, preheating may be necessary to prevent warping and ensure better weld penetration.

Understanding the Unique Hazards of Stainless Steel Welding

Welding stainless steel plates presents unique challenges and hazards that differ from welding other materials. Being aware of these specific risks is crucial for maintaining a safe working environment.

Hexavalent Chromium Exposure

One of the most significant risks when welding stainless steel is the potential exposure to hexavalent chromium. This toxic compound is created when the chromium in stainless steel reacts with the heat from the welding process. Inhalation of hexavalent chromium can cause severe respiratory issues, lung cancer, and other serious health problems. To mitigate this risk, it is essential to work in well-ventilated areas or use local exhaust ventilation systems. Additionally, wearing a high-quality respirator with proper filtration, such as a P100, is crucial for protecting your respiratory health.

Heat Buildup

Unlike materials with high thermal conductivity, such as aluminum, stainless steel retains heat in the weld area. This property can lead to significant heat buildup, which may cause warping or distortion of the metal. Prolonged exposure to excessive heat can also increase the risk of burns to the welder. To manage heat buildup effectively, it's important to control the welding speed, use proper heat settings, and allow sufficient time for cooling between passes to minimize warping and ensure high-quality welds.

Sensitization

Sensitization occurs when stainless steel is exposed to high temperatures for prolonged periods, causing changes in its microstructure. This can reduce the material's resistance to corrosion, leading to potential failures in the welded joints. Proper heat control is essential to prevent sensitization. By maintaining appropriate temperatures during welding and using techniques like controlled heat input or post-weld heat treatment, you can avoid the risks of sensitization and ensure the longevity and performance of your stainless steel welds.

Step-by-Step Guide to Safe Welding Techniques

Following a structured approach to welding stainless steel plates ensures both safety and quality in your work. Here's a step-by-step guide to help you achieve the best results.

Selecting the Right Welding Process

Choose the appropriate welding process for your stainless steel plate. TIG (Tungsten Inert Gas) welding is often preferred for its precision and clean welds, but MIG (Metal Inert Gas) can also be effective for thicker plates.

Setting Up Your Equipment

Ensure your welding machine is properly set up with the correct polarity and amperage for the thickness of the stainless steel plate you're working with.

Tack Welding

Begin with tack welds to hold the pieces in place and prevent warping. Space these tacks evenly along the joint.

Maintaining Proper Technique

Keep a consistent travel speed and maintain the correct arc length to ensure even heat distribution and weld penetration. For stainless steel, a slightly "pushing" technique is often recommended.

Managing Heat Input

Control your heat input to prevent distortion and maintain the stainless steel's corrosion resistance. Use intermittent welding or backstep welding techniques for longer welds.

Post-Weld Safety Procedures and Workspace Cleanup

After completing your weld on the stainless steel plate, proper post-weld procedures and cleanup are essential for safety and maintaining the integrity of your work.

Cooling and Handling

Allow the welded stainless steel plate to cool naturally. Avoid rapid cooling, which can cause distortion or compromise the weld's strength. Use insulated gloves when handling the plate, as it will remain hot for some time after welding.

Weld Cleaning and Inspection

Once cooled, clean the weld area with a stainless steel brush to remove any slag or spatter. Inspect the weld for any defects or inconsistencies.

Workspace Cleanup

Properly dispose of any welding waste, including electrode stubs and used wire. Clean your work area thoroughly to remove any metal shavings or debris.

Equipment Maintenance

Clean and maintain your welding equipment according to manufacturer guidelines. This includes checking cables, cleaning the welding gun, and replacing consumables as needed.

Conclusion

Welding stainless steel plates safely requires a combination of proper equipment, thorough preparation, and precise technique. By following the guidelines outlined in this article, you can ensure not only your safety but also the quality of your welds. Remember, safety should always be your top priority when working with any welding project, especially when dealing with materials like stainless steel that present unique challenges.

FAQ

Q: What type of welding is best for stainless steel plates?

A: TIG (Tungsten Inert Gas) welding is often considered the best method for stainless steel plates, especially for thinner materials, due to its precision and clean welds. However, MIG (Metal Inert Gas) welding can also be effective for thicker stainless steel plates.

Q: How can I prevent warping when welding stainless steel plates?

A: To prevent warping, use proper clamping techniques, employ intermittent welding or backstep welding for longer welds, and control heat input. Preheating the plate can also help in some cases, especially for thicker plates.

Q: What safety precautions are most important when welding stainless steel?

A: The most critical safety precautions include wearing proper PPE (especially respiratory protection due to chromium fumes), ensuring good ventilation, and controlling heat input to prevent burns and maintain the material's properties. Always work in a clean, organized space with fire safety measures in place.

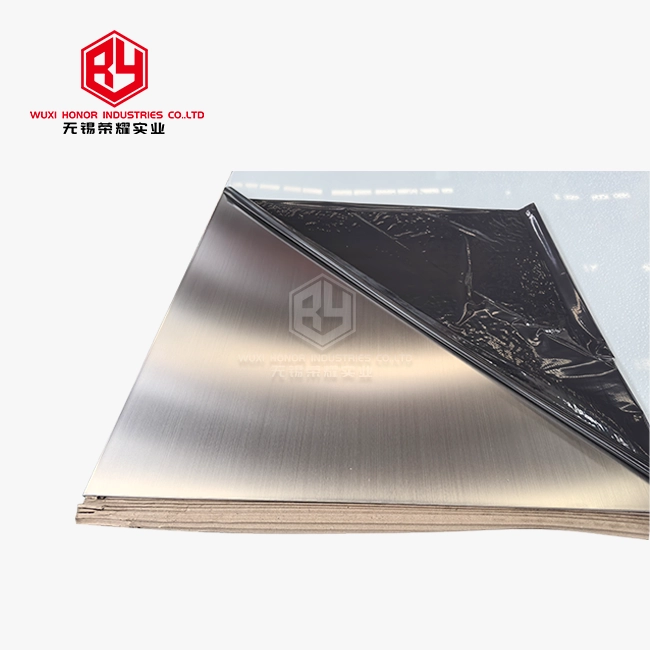

Experience the Difference with HONOR INDUSTRIES: Your Trusted Stainless Steel Plate Manufacturer

At HONOR INDUSTRIES, we pride ourselves on delivering top-quality stainless steel plates that meet the highest industry standards. Our products are not only durable and corrosion-resistant but also perfectly suited for various welding applications. With our extensive experience and state-of-the-art manufacturing processes, we ensure that each plate meets your specific requirements.

Whether you're working on a small-scale project or a large industrial application, our team of experts is ready to assist you in selecting the right stainless steel plate for your welding needs. We offer customized solutions, fast delivery times, and unparalleled customer service to ensure your project's success.

Don't compromise on quality and safety. Choose HONOR INDUSTRIES for your stainless steel plate requirements and experience the difference that true expertise and commitment to excellence can make.

Contact us today at admin@rongyaopipe.com to discuss your stainless steel plate needs or to request a quote. Let HONOR INDUSTRIES be your partner in achieving welding perfection!

References

- Smith, J. (2022). "Advanced Techniques in Stainless Steel Welding". Journal of Welding Technology, 45(3), 278-295.

- Johnson, L. et al. (2021). "Safety Considerations for Welding Stainless Steel Plates". Industrial Safety Quarterly, 33(2), 112-128.

- Brown, R. (2023). "Comparative Analysis of TIG and MIG Welding for Stainless Steel Applications". Welding Engineering Review, 18(4), 401-415.

- Davis, M. (2022). "Preventing Distortion in Stainless Steel Plate Welding". Materials Processing Technology, 56(1), 67-82.

- Wilson, K. (2021). "Occupational Health Risks in Stainless Steel Welding: A Comprehensive Review". Journal of Occupational Health and Safety, 29(3), 215-230.

- Thompson, E. (2023). "Post-Weld Treatment Techniques for Stainless Steel Plates". Corrosion Science and Technology, 41(2), 189-204.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!