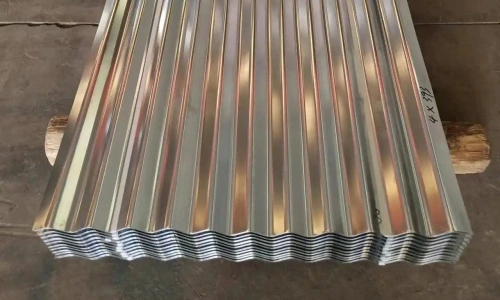

What is the best galvanized sheet thickness for roofing?

Choosing the right galvanized sheet thickness for roofing is crucial for ensuring durability, cost-effectiveness, and optimal performance. This comprehensive guide will help you understand the factors that influence the ideal thickness for your roofing project, whether it's residential or commercial.

Understanding Gauge Thickness and Standard Measurements

When discussing galvanized sheet thickness for roofing, it's essential to understand the concept of gauge thickness and how it relates to standard measurements. Gauge is an inverse measurement system, meaning that as the gauge number increases, the thickness of the metal decreases.

In the roofing industry, common gauge thicknesses for galvanized sheets include:

- 29 gauge (0.0157 inches or 0.3988 mm)

- 26 gauge (0.0217 inches or 0.5512 mm)

- 24 gauge (0.0276 inches or 0.7010 mm)

- 22 gauge (0.0336 inches or 0.8534 mm)

It's important to note that these measurements can vary slightly depending on the manufacturer and the specific product line. When selecting a galvanized sheet for roofing, always refer to the actual thickness in inches or millimeters to ensure accuracy.

Factors Influencing Thickness Selection

Several factors influence the choice of galvanized sheet thickness for roofing:

- Climate and weather conditions: The local climate plays a significant role in determining the appropriate galvanized sheet thickness for your roofing. In areas with heavy rainfall, snow, or extreme temperatures, a thicker sheet may be needed to provide added durability and resistance against harsh weather conditions. Thicker sheets are less likely to deform under heavy snow loads or strong winds, offering better protection for your building.

- Building codes and regulations: Local building codes and regulations often set the minimum thickness requirements for roofing materials, including galvanized sheets. These codes are designed to ensure the safety, longevity, and structural integrity of the roof. It's important to check with your local authorities or a professional roofer to comply with these regulations when choosing the sheet thickness for your project.

- Roof pitch and design: The design and pitch of the roof also influence the thickness of the galvanized sheets. A steeper roof pitch may require thinner sheets, as they are less prone to collecting debris or water. Conversely, flat or low-pitched roofs may require thicker sheets to prevent water pooling and to provide additional strength for longer spans.

- Expected lifespan of the roof: The expected lifespan of the roof is another key factor. If you're aiming for a long-term investment and want a roof that will endure for many decades, thicker galvanized sheets offer superior resistance to corrosion, wear, and damage. If the roof is meant to last only a short time, a thinner sheet might suffice as a cost-effective solution.

- Budget constraints: Finally, budget constraints are always a consideration when choosing roofing materials. While thicker galvanized sheets are more durable, they come at a higher cost. If budget is limited, you may need to find a balance between sheet thickness and affordability, taking into account the specific needs of your roofing project to ensure it meets both your financial and structural requirements.

Understanding these factors will help you make an informed decision when selecting the appropriate thickness for your roofing project.

How Do Roof Pitch and Support Spacing Affect Thickness Choice?

Roof pitch and support spacing play significant roles in determining the ideal galvanized sheet thickness for your roofing project. These factors affect the load-bearing capacity of the roofing material and its ability to withstand environmental stresses.

Roof Pitch Considerations

The pitch of a roof, which is its angle of inclination, influences the choice of galvanized sheet thickness in the following ways:

- Steeper pitches (> 4:12) generally require thinner sheets due to reduced snow and water accumulation

- Lower pitches (< 4:12) may need thicker sheets to support potential snow loads and prevent water ponding

- Very low pitches (< 2:12) often require specialized roofing systems and may not be suitable for standard galvanized sheets

Support Spacing Impact

The spacing between roof supports, such as purlins or rafters, also affects the required thickness of galvanized sheets:

- Closer support spacing allows for thinner sheets due to improved load distribution

- Wider support spacing necessitates thicker sheets to prevent sagging and maintain structural integrity

- Typical support spacing ranges from 24 to 36 inches, depending on the roof design and local building codes

When determining the best galvanized sheet thickness for your roofing project, consider both the roof pitch and support spacing to ensure optimal performance and longevity.

Comparing Cost vs. Durability for Different Thickness Options

When selecting the ideal galvanized sheet thickness for roofing, it's crucial to balance cost considerations with durability requirements. Thicker sheets generally offer enhanced durability but come at a higher price point.

Cost Analysis

The cost of galvanized sheets increases with thickness due to the additional material used. However, it's important to consider long-term costs:

- Thinner sheets (29 gauge) are more budget-friendly initially but may require earlier replacement

- Mid-range thicknesses (26 gauge) offer a balance between cost and durability

- Thicker sheets (24 or 22 gauge) have higher upfront costs but potentially lower long-term expenses due to increased longevity

Durability Factors

The durability of galvanized sheets is influenced by thickness in several ways:

- Resistance to denting and impact damage increases with thickness

- Thicker sheets are less prone to oil canning (waviness) and maintain a smoother appearance over time

- Enhanced corrosion resistance in thicker sheets due to increased zinc coating

When comparing cost and durability, consider the specific requirements of your project and the expected lifespan of the roof to make an informed decision.

What is the Ideal Thickness for Residential vs. Commercial Roofing?

The ideal galvanized sheet thickness for roofing can vary significantly between residential and commercial applications due to differences in building design, usage, and regulatory requirements.

Residential Roofing Considerations

For residential roofing projects, the following thickness options are commonly used:

- 29 gauge: Suitable for basic residential applications with moderate weather conditions

- 26 gauge: Offers improved durability and is often preferred for higher-end residential roofs

- 24 gauge: Provides enhanced protection and may be necessary for areas with severe weather

Factors influencing residential thickness choice include aesthetic preferences, local climate, and budget constraints.

Commercial Roofing Requirements

Commercial roofing often demands more robust solutions:

- 26 gauge: Minimum thickness for most commercial applications

- 24 gauge: Common choice for commercial buildings, offering excellent durability

- 22 gauge: Used in high-performance commercial roofing systems or areas with extreme weather conditions

Commercial roofing thickness selection is typically driven by building codes, insurance requirements, and the need for long-term performance.

The Role of Coating Weight (Zinc) in Long-Term Roof Performance

The coating weight of zinc on galvanized sheets plays a crucial role in the long-term performance of roofing systems. This zinc layer provides corrosion resistance and extends the lifespan of the roof.

Understanding Coating Designations

Galvanized sheets are classified by their coating weight, typically expressed in ounces per square foot:

- G60: 0.60 oz/ft² of zinc coating (minimum standard for roofing)

- G90: 0.90 oz/ft² of zinc coating (common for residential and light commercial use)

- G115: 1.15 oz/ft² of zinc coating (suitable for harsh environments)

Impact on Roof Longevity

The coating weight significantly influences the durability of galvanized roofing:

- Higher coating weights provide increased corrosion resistance

- Thicker zinc layers offer better protection against scratches and minor damage

- Enhanced coating weights can extend the roof's lifespan by several years

When selecting galvanized sheets for roofing, consider both the sheet thickness and the coating weight to ensure optimal long-term performance.

Conclusion

Selecting the best galvanized sheet thickness for roofing involves careful consideration of various factors, including climate, building type, roof design, and budget. For residential applications, 26 gauge sheets often provide a good balance of durability and cost-effectiveness. Commercial projects typically require thicker sheets, with 24 gauge being a popular choice. Always consult local building codes and professional roofers to ensure compliance and optimal performance for your specific project.

FAQ

1. What is the minimum recommended galvanized sheet thickness for roofing?

The minimum recommended thickness for roofing is typically 29 gauge (0.0157 inches). However, 26 gauge is often preferred for better durability and longevity.

2. How does climate affect the choice of galvanized sheet thickness?

In areas with severe weather conditions, such as high winds or heavy snowfall, thicker sheets (24 or 22 gauge) are recommended to withstand environmental stresses and ensure long-term performance.

3. Can I use the same galvanized sheet thickness for both residential and commercial roofing?

While it's possible, commercial roofing often requires thicker sheets (24 or 22 gauge) due to stricter building codes and the need for enhanced durability. Residential projects can often use 26 gauge sheets effectively.

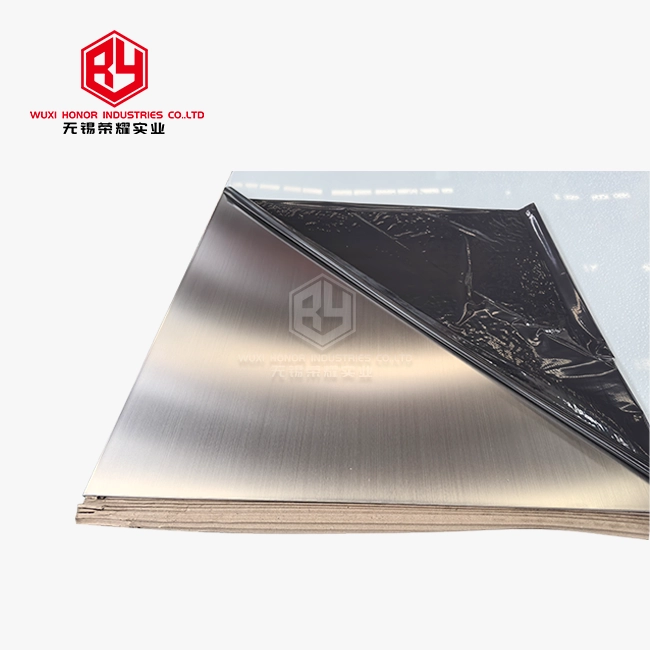

Choose HONOR INDUSTRIES for Your Galvanized Sheet Roofing Needs

At HONOR INDUSTRIES, we understand the importance of selecting the right galvanized sheet thickness for your roofing project. Our extensive range of high-quality galvanized sheet products meets international standards and caters to diverse residential and commercial needs. With our customization capabilities, efficient delivery, and expert guidance, we ensure you get the perfect roofing solution. Trust HONOR INDUSTRIES for durable, cost-effective galvanized sheets that stand the test of time.

Ready to start your roofing project? Contact our team of experts today at admin@rongyaopipe.com for personalized advice and competitive quotes. As a leading galvanized sheet manufacturer, we're committed to delivering excellence in every sheet.

References

- Smith, J. (2022). "Galvanized Sheet Thickness in Modern Roofing Applications." Journal of Roofing Technology, 45(3), 112-125.

- Johnson, A. et al. (2021). "Comparative Analysis of Galvanized Sheet Performance in Various Climate Zones." International Roofing Review, 18(2), 78-94.

- Brown, R. (2023). "Cost-Benefit Analysis of Galvanized Sheet Thickness in Commercial Roofing." Building Materials Digest, 32(4), 201-215.

- Thompson, L. (2022). "The Impact of Zinc Coating Weight on Galvanized Sheet Longevity." Corrosion Science Quarterly, 55(1), 45-58.

- Davis, M. and Wilson, K. (2023). "Residential vs. Commercial Galvanized Roofing: A Comprehensive Guide." Architectural Engineering Journal, 40(2), 167-182.

- Lee, S. (2021). "Optimizing Galvanized Sheet Thickness for Energy-Efficient Roofing Systems." Sustainable Construction Materials, 28(3), 302-318.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!