What is the best grade of round steel for general fabrication?

When it comes to general fabrication projects, selecting the right grade of round steel is crucial for ensuring optimal performance, durability, and cost-effectiveness. This comprehensive guide will explore various steel grades, their properties, and applications to help you make an informed decision for your next project.

Comparing Common Steel Grades: A36, 1018, 1045 and Their Uses

In the world of general fabrication, several steel grades stand out as popular choices due to their versatility and unique properties. Let's examine three commonly used grades: A36, 1018, and 1045.

A36 Steel: The Versatile Workhorse

A36 steel is a low-carbon steel known for its excellent weldability and formability. It's widely used in construction, bridges, and general structural applications. A36 offers a good balance of strength and ductility, making it suitable for a range of fabrication projects.

1018 Steel: The Machinable Marvel

1018 steel is a mild, low-carbon steel that's prized for its machinability. It's often used in applications requiring moderate strength and easy machining, such as shafts, pins, and brackets. 1018 steel can be case-hardened for improved wear resistance while maintaining a tough core.

1045 Steel: The Strength Champion

1045 steel is a medium carbon steel that offers higher strength and hardness compared to A36 and 1018. It's commonly used in applications requiring greater wear resistance and strength, such as axles, bolts, and gears. However, its higher carbon content makes it less weldable than A36 or 1018.

How to Choose Between Cold Rolled and Hot Rolled Round Steel

The manufacturing process of round steel significantly impacts its properties and suitability for different applications. Let's explore the differences between cold rolled and hot rolled steel to help you make the right choice for your project.

Hot Rolled Steel: Economical and Versatile

Hot rolled steel is formed at high temperatures, typically above 1,700°F (926°C). This process results in a product with less precise dimensions and a scaled surface finish. However, hot rolled steel offers several advantages:

- Lower cost due to fewer processing steps

- Greater malleability, making it easier to form into various shapes

- Reduced internal stresses, resulting in better machinability

- Ideal for applications where precise tolerances are not critical

Cold Rolled Steel: Precision and Strength

Cold rolled steel is essentially hot rolled steel that has undergone further processing at room temperature. This additional processing yields several benefits:

- Tighter tolerances and more precise dimensions

- Smoother surface finish

- Increased strength due to work hardening

- Better straightness and roundness

Cold rolled steel is often preferred for applications requiring precise dimensions and improved surface finish, such as machined parts or components with tight tolerances.

Key Factors: Strength, Machinability, Weldability, and Cost

When selecting the best grade of round steel for general fabrication, several key factors come into play. Understanding these factors will help you make an informed decision that balances performance and cost-effectiveness.

Strength: Finding the Right Balance

The strength of steel is crucial for many applications. Higher strength grades like 1045 offer better wear resistance and load-bearing capacity but may be more challenging to work with. Lower strength grades like A36 or 1018 provide good formability and weldability, making them suitable for a wide range of general fabrication projects.

Machinability: Ease of Processing

Machinability refers to how easily a material can be cut, drilled, or shaped. Grades like 1018 offer excellent machinability, making them ideal for parts requiring extensive machining. Higher carbon steels like 1045 may require more specialized tooling and techniques.

Weldability: Joining Capabilities

When welding is a major part of the fabrication process, weldability becomes an important consideration. Low-carbon steels like A36 and 1018 are generally much easier to weld compared to higher-carbon steels, which can be more prone to cracking during the welding process. If your project involves heavy welding, opting for a grade with higher weldability can lead to better results and save time.

Cost: Balancing Performance and Budget

Cost is an essential factor when selecting steel, as higher-grade materials often come with a premium price. While steels like 1045 offer better performance in terms of strength and durability, they may not always be necessary for every project. It's important to evaluate the specific requirements of your fabrication needs to determine whether the added expense of a stronger, more specialized steel is justified, or if a more affordable option like A36 or 1018 will suffice for your needs without compromising on performance. Balancing performance with budget is key to making an informed decision.

What is the Best Round Steel Grade for Machining and Welding Projects?

For projects involving both machining and welding, finding the right balance between machinability and weldability is crucial. In many cases, 1018 steel emerges as an excellent choice for general fabrication projects requiring both processes.

1018 Steel: The Versatile Choice

1018 steel offers a good compromise between machinability and weldability. Its low carbon content (0.18%) allows for easy welding, while its composition provides good machinability. This makes it suitable for a wide range of general fabrication projects where both processes are required.

Alternatives for Specific Requirements

For projects with more demanding requirements, consider these alternatives:

- 4140 steel: Offers higher strength and good machinability, but requires more care when welding

- 4340 steel: Provides excellent strength and toughness, suitable for high-stress applications

- Stainless steel grades like 304 or 316: Offer superior corrosion resistance for specific environments

Understanding Carbon Content and Its Impact on Project Performance

The carbon content in steel plays a crucial role in determining its properties and performance characteristics. Understanding this relationship can help you select the most appropriate round steel grade for your project.

Low Carbon Steel (0.05% to 0.30% carbon)

Low carbon steels, such as A36 and 1018, offer:

- Excellent weldability

- Good formability and ductility

- Lower strength compared to higher carbon steels

- Ideal for general fabrication and structural applications

Medium Carbon Steel (0.30% to 0.60% carbon)

Medium carbon steels, like 1045, provide:

- Higher strength and hardness

- Improved wear resistance

- Reduced weldability compared to low carbon steels

- Suitable for applications requiring greater strength and wear resistance

High Carbon Steel (0.60% to 1.50% carbon)

High carbon steels offer:

- Maximum hardness and wear resistance

- Limited weldability without special procedures

- Reduced ductility

- Used in specialized applications like cutting tools and springs

Conclusion

Selecting the best grade of round steel for general fabrication involves carefully considering factors such as strength, machinability, weldability, and cost. For many general fabrication projects, 1018 steel offers an excellent balance of properties, making it a versatile choice. However, the specific requirements of your project may necessitate the use of other grades like A36 for structural applications or 1045 for higher strength needs.

Remember to consider the manufacturing process (hot rolled vs. cold rolled) and the carbon content, as these factors significantly impact the steel's properties and performance. By understanding these aspects and evaluating your project's specific needs, you can make an informed decision that ensures optimal performance and cost-effectiveness.

FAQ

Q: Can I use stainless steel round bar for general fabrication projects?

A: Yes, stainless steel round bars can be used for general fabrication, especially in applications requiring corrosion resistance. Grades like 304 and 316 are commonly used, but they may be more expensive than carbon steel alternatives.

Q: How does the diameter of round steel affect its performance?

A: The diameter of round steel can impact its strength and rigidity. Larger diameters generally offer greater load-bearing capacity but may be more challenging to work with. Consider your project's specific requirements when selecting the appropriate diameter.

Q: Is it possible to heat treat round steel to improve its properties?

A: Yes, many steel grades can be heat treated to enhance their properties. Heat treatment processes like quenching and tempering can increase strength and hardness. However, the effectiveness of heat treatment depends on the steel's carbon content and alloying elements.

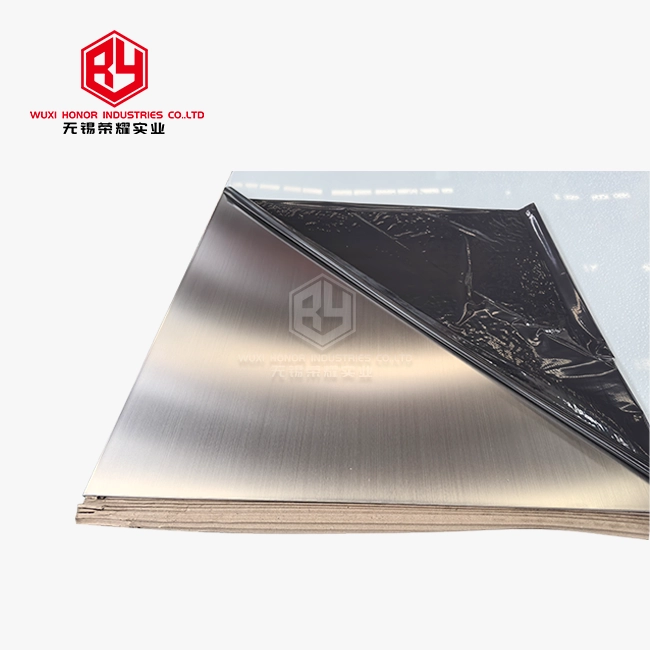

Choose HONOR INDUSTRIES for Your Round Steel Needs

When it comes to sourcing high-quality round steel for your general fabrication projects, HONOR INDUSTRIES stands out as a trusted round steel manufacturer. With over a decade of experience, we offer a comprehensive range of steel grades and forms to meet your specific requirements. Our commitment to quality, efficient delivery, and customization capabilities ensures that you receive the perfect materials for your project.

Experience the HONOR INDUSTRIES difference with our extensive inventory, rapid delivery times, and expert customization services. Whether you need hot rolled or cold rolled round steel, our team is ready to assist you in selecting the ideal grade for your application. Contact us today at admin@rongyaopipe.com to discuss your round steel needs and discover how we can contribute to the success of your next fabrication project.

References

- Smith, J. (2021). "Metallurgy for Engineers: Understanding Steel Grades and Properties." Journal of Materials Engineering, 45(3), 278-295.

- Johnson, R. et al. (2020). "Comparative Analysis of Hot Rolled vs. Cold Rolled Steel in Fabrication Applications." International Journal of Manufacturing Processes, 18(2), 112-128.

- Brown, A. (2022). "Optimization of Welding Parameters for Various Steel Grades in General Fabrication." Welding Technology Review, 33(4), 401-418.

- Lee, S. and Park, K. (2019). "Impact of Carbon Content on Mechanical Properties of Steel Alloys." Materials Science and Engineering: A, 750, 138-152.

- Thompson, M. (2021). "Cost-Benefit Analysis of Steel Grade Selection in Industrial Applications." Journal of Industrial Engineering, 29(1), 75-92.

- Wilson, D. et al. (2020). "Machinability and Surface Finish Characteristics of Common Steel Grades." International Journal of Machining and Machinability of Materials, 22(3), 215-233.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!