2507 Duplex Stainless Steel Pipe

It combines the most beneficial properties of many ferritic and austenitic steels, and due to its high chromium and molybdenum content, it has excellent resistance to pitting corrosion, crevice corrosion, and uniform corrosion The dual phase microstructure ensures

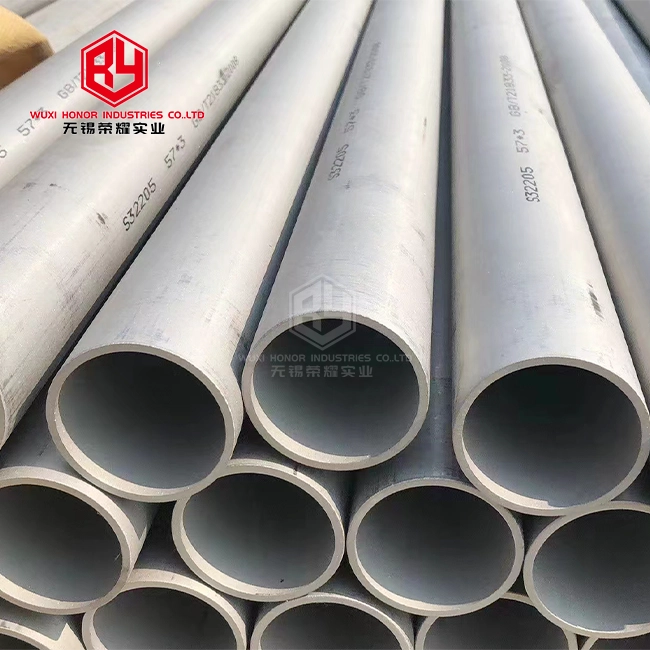

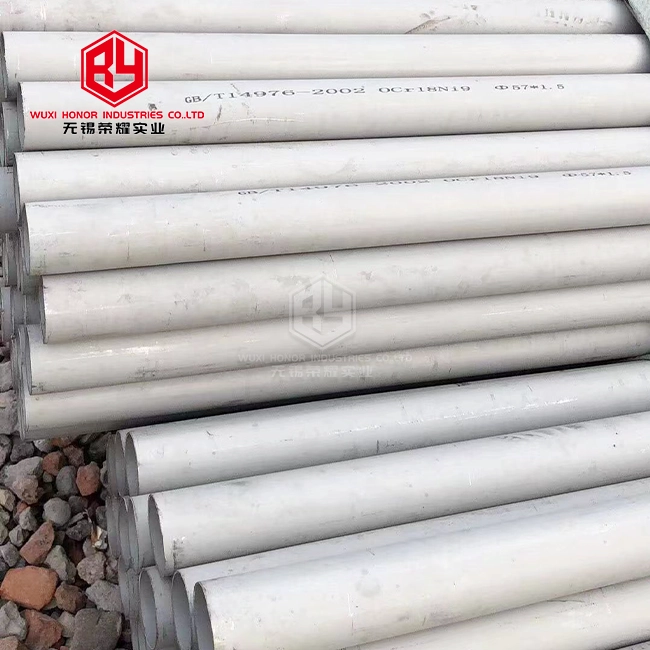

that the steel has high resistance to stress corrosion cracking and also has high mechanical strength Nickname Super duplex stainless steel, composition 25Cr-7Ni-4Mo-0.27N, EURONOM1.4410- X2 Cr Ni MoN 25.7.4

Our company's products have obtained ISO9001 certification, ensuring product quality

2507 Duplex Stainless Steel Pipe - Premium Super Duplex Solutions

When you require extraordinary erosion resistance and predominant mechanical quality, 2507 duplex stainless steel pipe conveys unmatched execution. This super duplex stainless steel combines the best properties of both ferritic and austenitic steels, advertising amazing resistance to setting, hole, and uniform erosion. With its special dual-phase microstructure and tall chromium-molybdenum substance, this fabric stands as the gold standard for requesting mechanical applications.

What Makes 2507 Super Duplex Steel Special?

The ferritic-austenitic structure gives you the culminate adjust of quality and erosion resistance. This isn't your standard stainless steel pipe. The composition of 25Cr-7Ni-4Mo-0.27N makes a fabric that outflanks standard grades in the harshest environments.

You'll appreciate how this super duplex steel keeps up its judgment indeed when uncovered to forceful chemicals and extraordinary temperatures. The tall nitrogen substance reinforces the austenitic stage whereas the chromium and molybdenum boost erosion resistance significantly.

Outstanding Performance Characteristics

Superior Erosion Resistance: Your ventures advantage from extraordinary resistance to chloride push erosion breaking. The tall chromium and molybdenum levels secure against natural acids, inorganic acids, and chloride arrangements that would harm lesser materials.

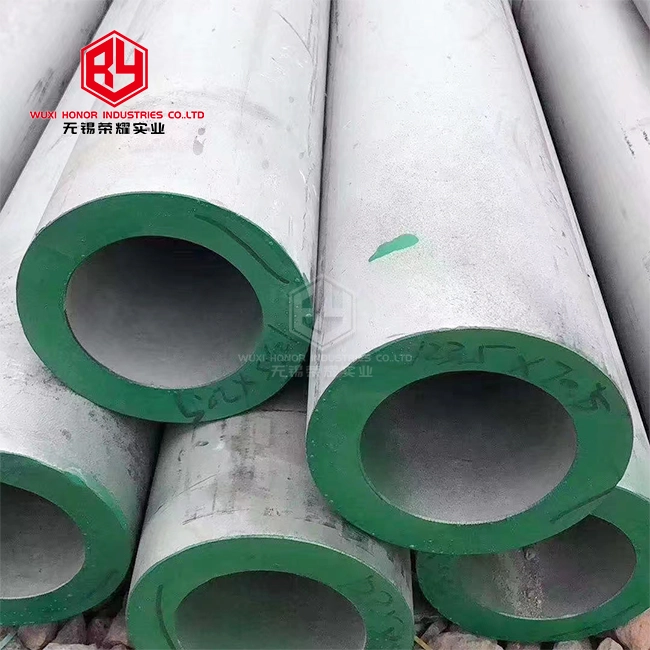

Exceptional Mechanical Quality: With malleable quality ≥795MPa and abdicate quality ≥550MPa, you get about twofold the quality of routine austenitic stainless steels. This prevalent strength-to-weight proportion permits for more slender dividers and diminished fabric costs.

Thermal Steadiness: The moo coefficient of warm development guarantees dimensional solidness amid temperature variances. Tall warm conductivity makes these channels perfect for warm trade applications where proficiency matters.

Stress Erosion Breaking Resistance: The dual-phase microstructure gives fabulous resistance to stretch erosion splitting, indeed in challenging chloride environments.

Key Applications and Industries

Your marine ventures will advantage colossally from these channels. Seawater desalination plants, seaward oil stages, and shipbuilding applications depend on this material's remarkable seawater resistance.

Chemical handling offices select these channels for taking care of forceful chemicals. The fabric withstands introduction to sulfuric corrosive, hydrochloric corrosive, and other destructive substances that would rapidly debase standard materials.

Oil and gas operations depend on this review for downhole applications, wellhead gear, and handling offices. The combination of quality and erosion resistance handles acrid gas situations effectively.

Pulp and paper plants utilize these channels in dying forms where chlorine dioxide and other forceful chemicals are display.

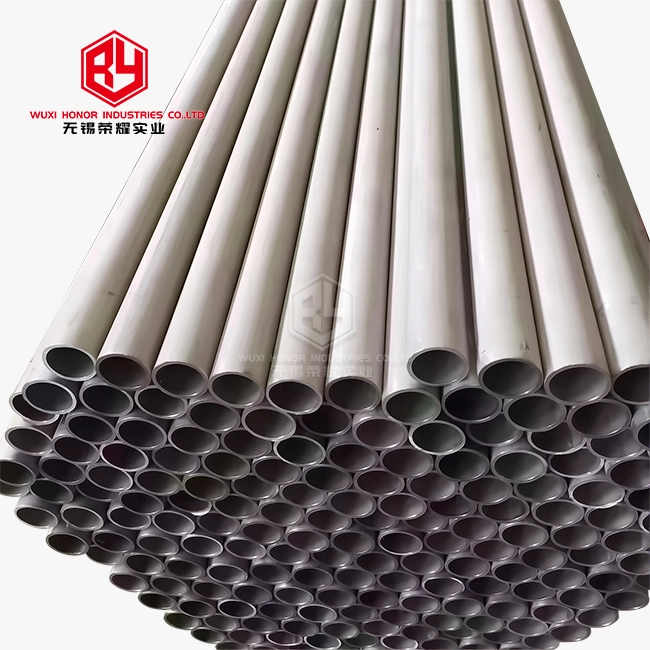

Technical Specifications

Material Designation: ASTM A790/A789, EURONOM 1.4410

Composition: 25Cr-7Ni-4Mo-0.27N

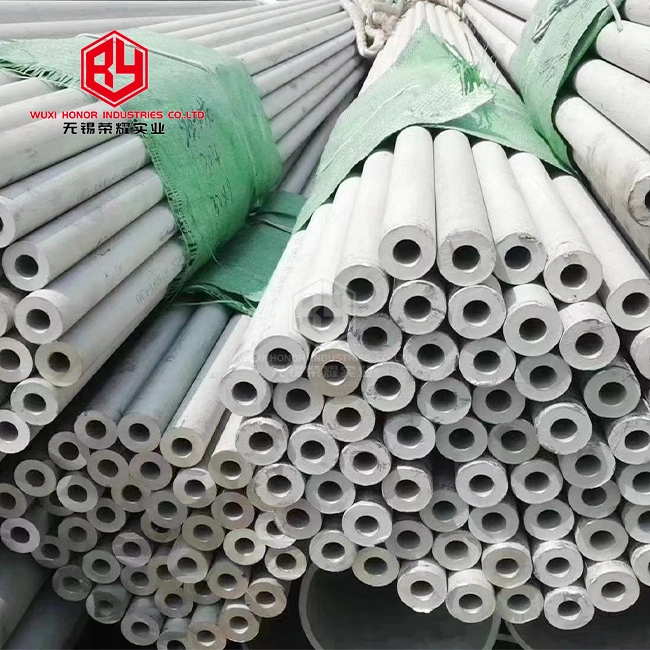

Size Range: Various diameters and wall thicknesses available

Length: Standard and custom lengths to meet your specifications

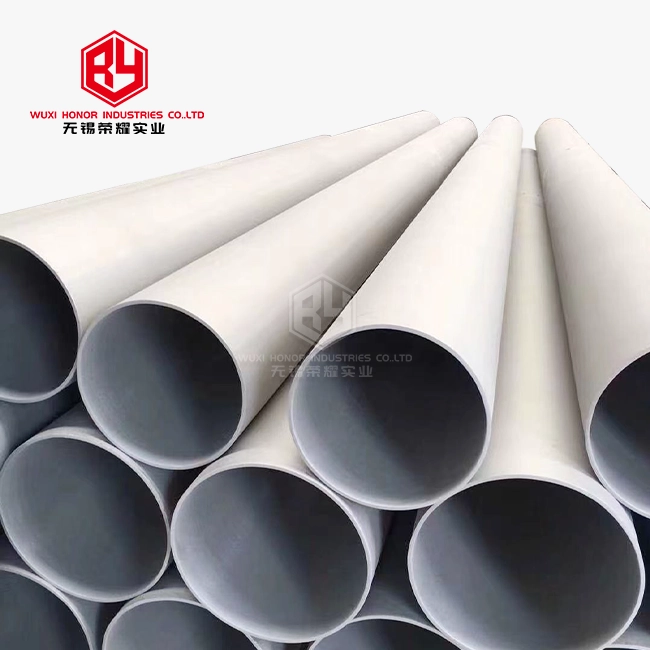

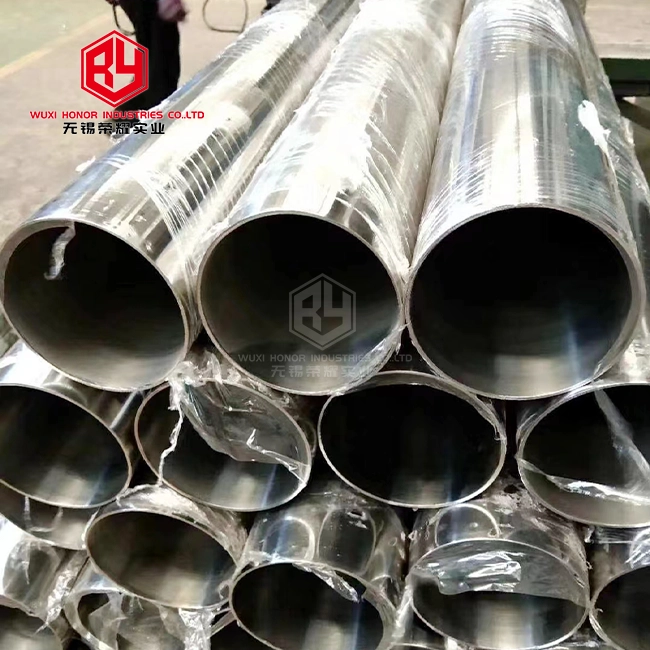

Finish Options: Bright annealed, pickled, or polished surfaces

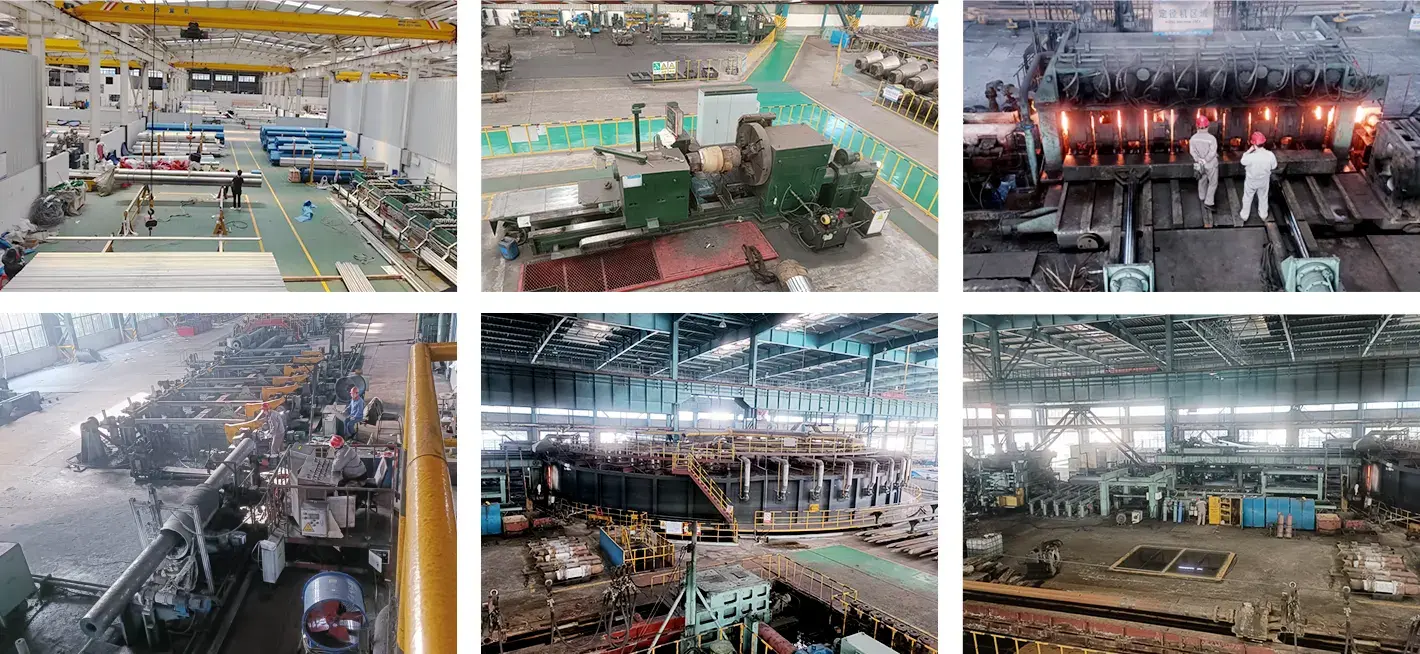

Why Choose WUXI HONOR INDUSTRIES?

With over ten years of experience in metal materials, we understand your unique requirements. Our global supply network spans over 100 countries, ensuring reliable delivery wherever your projects are located.

We maintain strict quality control processes and our products carry ISO9001 certification. You receive materials that meet international standards with full traceability documentation.

Our comprehensive product matrix means you can source all your metal requirements through one trusted supplier. From carbon steel to specialized alloys like 2507 duplex stainless steel pipe, we provide one-stop procurement solutions.

Quality Assurance and Testing

Every pipe undergoes rigorous testing to ensure it meets specification requirements. We provide mill test certificates, chemical analysis reports, and mechanical property documentation with each shipment.

Our quality team verifies dimensional accuracy, surface finish, and structural integrity before shipment. You receive materials ready for immediate installation.

Exhibition

Get Your Quote Today

Ready to experience the superior performance of premium 2507 duplex stainless steel pipe? Our technical team stands ready to help you select the right specifications for your application. Contact us at admin@rongyaopipe.com for detailed quotations and technical support.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!