310S Stainless Steel Pipe

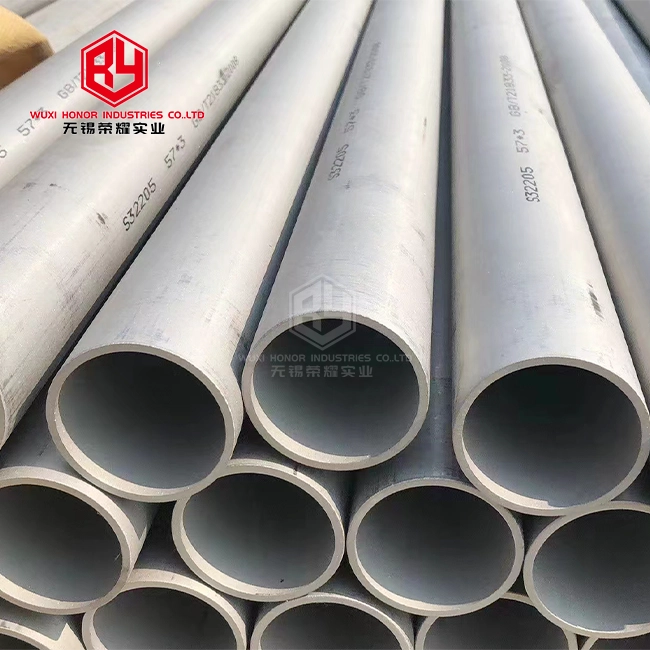

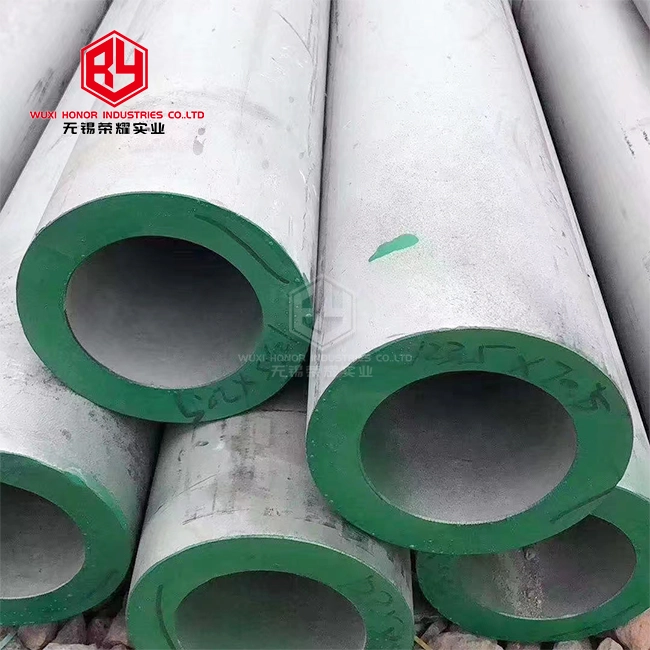

310S stainless steel has a tensile strength of ≥ 520MPa, a yield strength of ≥ 205MPa, an elongation rate of ≥ 40%, and a melting point of 1398 ℃~1454 ℃. The softening temperature starts at 800 ℃ and can be improved by solution treatment at 1030 ℃~1180 ℃.

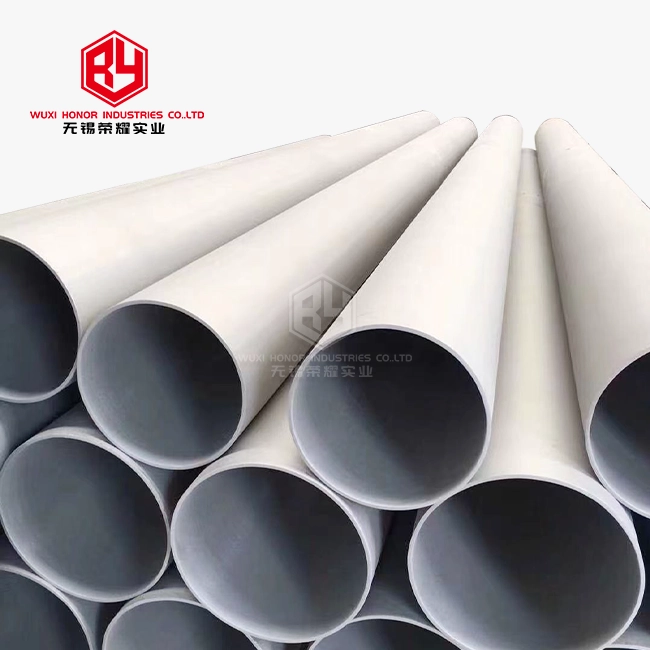

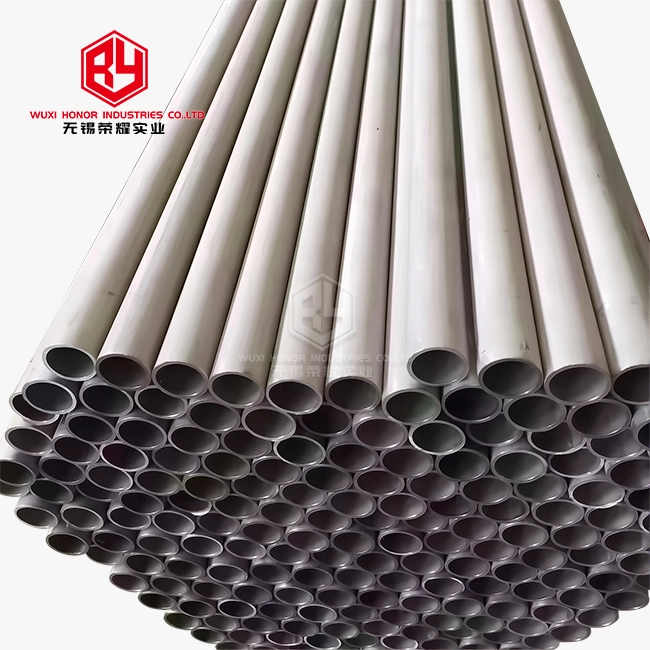

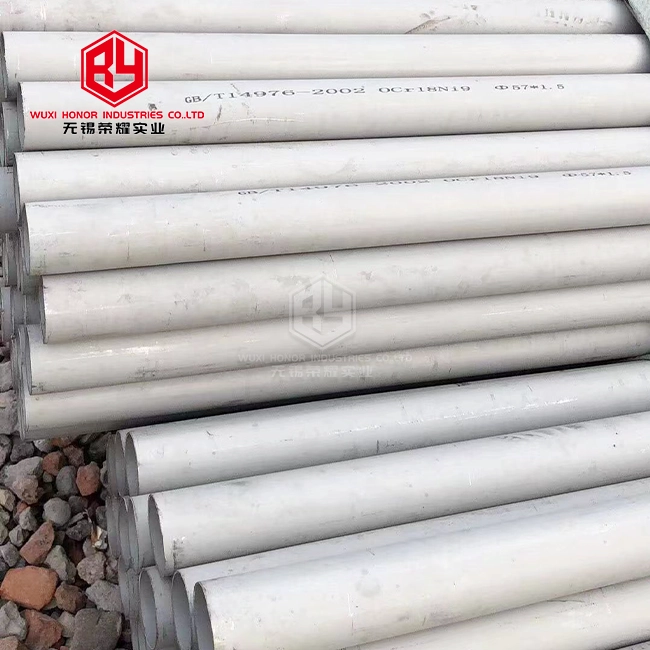

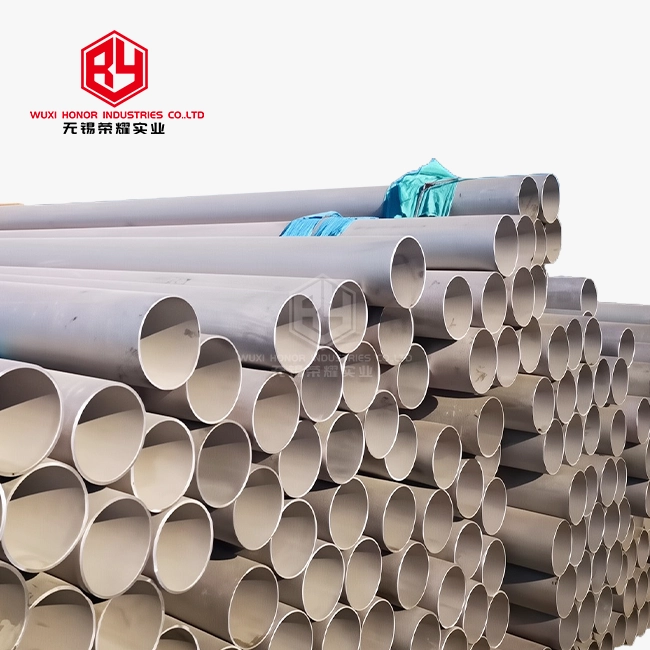

Mainly used in the manufacturing of high-temperature equipment components such as electric furnace tubes, heat treatment furnaces, combustion chambers, and heat exchangers, suitable for high-temperature environments such as petrochemicals, energy, and coke oven riser heat exchangers. The seamless pipe production process includes hot rolling perforation, cold rolling processing, and acid washing, while the welded pipe adopts a combined process of strip welding and solution heat treatment.

Our company's products have obtained ISO9001 certification, ensuring product quality

310S Stainless Steel Pipe - Premium High-Temperature Piping Solution

When you require dependable high-temperature channeling arrangements, 310S stainless steel pipe stands as your head choice for requesting mechanical applications. This extraordinary austenitic chromium-nickel steel pipe offers unmatched execution in extraordinary situations where standard materials come up short. With nonstop working temperatures coming to 1150°C and greatest working temperatures up to 1200°C, our channels convey the unwavering quality your ventures request. At WUXI HONOR Businesses CO.LTD, we combine over ten a long time of mastery with worldwide supply chain fabulousness to bring you prevalent quality materials that meet worldwide standards.

Superior High-Temperature Performance

You'll discover that our high-grade steel channels exceed expectations where others cannot. The carefully adjusted chemical composition highlights 24.00-26.00% chromium and 19.00-22.00% nickel substance. This exact detailing guarantees extraordinary oxidation resistance and erosion security in cruel environments.

Your hardware benefits from remarkable mechanical properties. Each pipe conveys ductile quality surpassing 520MPa and surrender quality over 205MPa. The prolongation rate of 40% or higher ensures adaptability beneath warm stress.

Temperature resistance sets these channels separated from ordinary materials. You can depend on nonstop operation at 1150°C without execution corruption. Short-term presentation to 1200°C postures no risk to auxiliary integrity.

Versatile Industrial Applications

Your high-temperature ventures discover idealize arrangements with our flexible channeling frameworks. Electric heater applications advantage from predominant warm resistance and dimensional solidness. Warm treatment offices depend on our channels for steady execution and longevity.

Petrochemical businesses select our items for basic applications. Combustion chambers require materials that withstand extraordinary warm cycling. Warm exchangers require corrosion-resistant channels that keep up effectiveness over time.

Energy segment experts believe our channels for requesting situations. Coke broiler riser applications grandstand the material's extraordinary strength. Chemical preparing offices depend on our items for secure, solid operations.

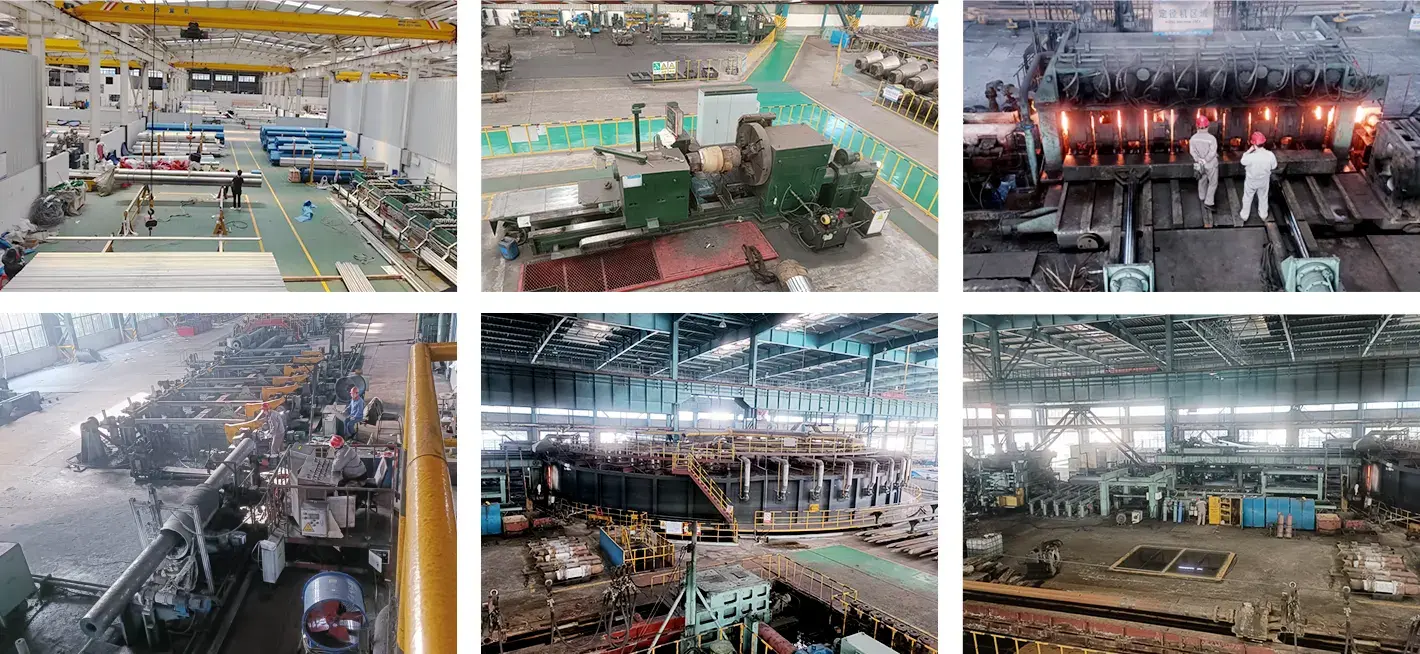

Manufacturing Excellence and Quality Assurance

You receive products manufactured to the highest standards. Our production follows Chinese GB/T14976-2012 specifications, ensuring consistent quality. Both seamless and welded options are available to meet your specific requirements.

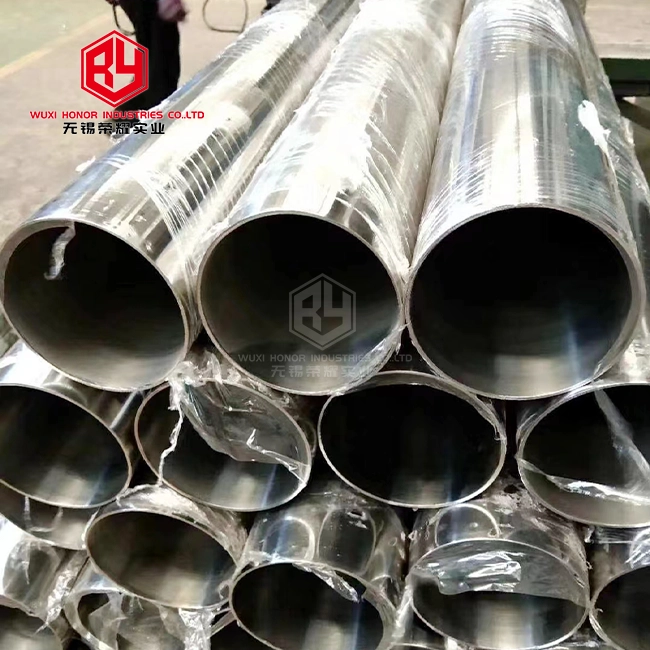

Seamless pipe production utilizes hot rolling perforation and cold rolling processes. Acid washing treatment provides superior surface finish and cleanliness. Welded pipes undergo strip welding followed by solution heat treatment for optimal properties.

Quality control remains paramount throughout production. Each 310S stainless steel pipe undergoes rigorous testing before shipment. Our ISO9001 certification demonstrates our commitment to excellence and customer satisfaction.

Certificate

Global Supply Chain Advantage

Your international projects benefit from our extensive global network. We serve customers in over 100 countries worldwide with reliable supply chain solutions. Our decade-plus experience in foreign trade ensures smooth cross-border transactions.

Logistics expertise streamlines your procurement process. We understand customs procedures and trade policies across different regions. This knowledge translates to faster delivery and reduced complications for your projects.

Long-term partnerships with premium steel mills guarantee material quality. You receive authentic products with full traceability documentation. Our supplier relationships ensure consistent availability and competitive pricing.

Exhibition

Technical Support and Service Excellence

You gain access to comprehensive technical assistance throughout your project lifecycle. Our experienced team provides guidance on material selection and application requirements. We offer customized solutions tailored to your specific operational needs.

Installation support helps ensure optimal performance from your 310S stainless steel pipe systems. We provide welding recommendations and joining procedures for various applications. Technical documentation accompanies every shipment for reference and compliance.

Flexible ordering accommodates projects of all sizes. Whether you need standard dimensions or custom specifications, we deliver solutions that match your requirements. Quick response times keep your projects on schedule and within budget.

Why Choose WUXI HONOR INDUSTRIES

Your success drives our commitment to excellence in metal materials supply. Our comprehensive product matrix covers all major metal categories with consistent quality standards. This one-stop approach simplifies procurement and reduces supplier management complexity.

Reputation built over ten years reflects our dedication to customer satisfaction. International clients trust us for critical applications where failure is not an option. Our business philosophy emphasizes long-term relationships over short-term gains.

Contact our team today at admin@rongyaopipe.com to discuss your high-temperature piping requirements. We're ready to provide expert guidance and competitive solutions for your next project using premium 310S stainless steel pipe products.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!