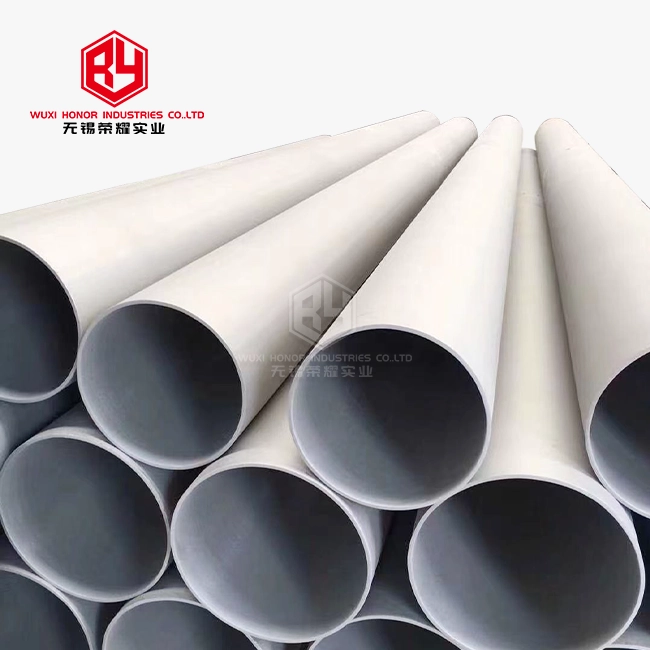

Stainless Steel Seamless Pipe

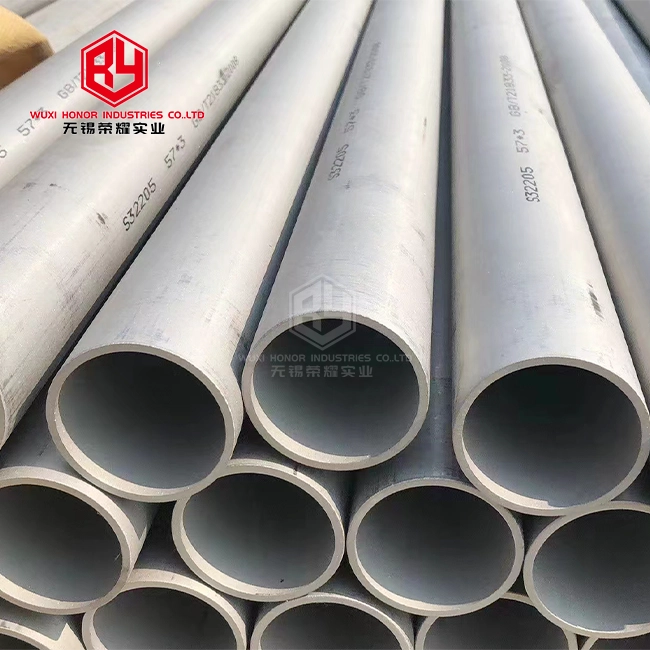

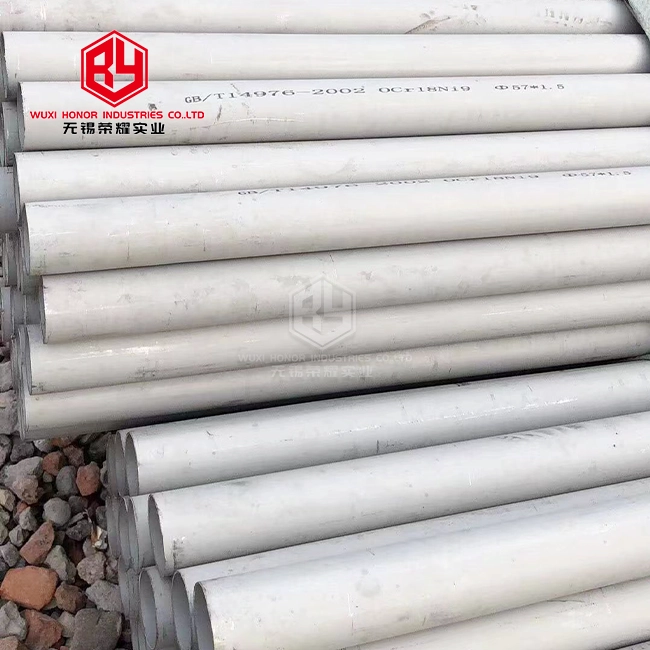

The diameter of the hot rolled tube is 54-480mm, and the diameter of the cold drawn tube is 6-200mm. The product complies with national standards such as GB/T14976 fluid transport tube and GB13296 boiler tube, covering international specifications such as ASTM A213 and JIS G3456. Production cost control measures include optimizing raw material procurement, improving production processes, enhancing equipment utilization efficiency, and strengthening personnel training.

Mainly used in the fields of building water supply systems, hot water supply, high-pressure pipelines, and mechanical structural materials, the detection process requires offline hydraulic testing, chemical analysis, and corrosion testing.

The surface quality requirements are no cracks or folding defects, and the straight depth is strictly controlled according to the wall thickness ratio. It exhibits significant advantages in high-pressure and high-strength application scenarios, but has limitations such as high cost of sizing and low brightness of pipe materials.

Our company's products have obtained ISO9001 certification, ensuring product quality

Stainless Steel Seamless Pipe: Your Premium Solution for Industrial Applications

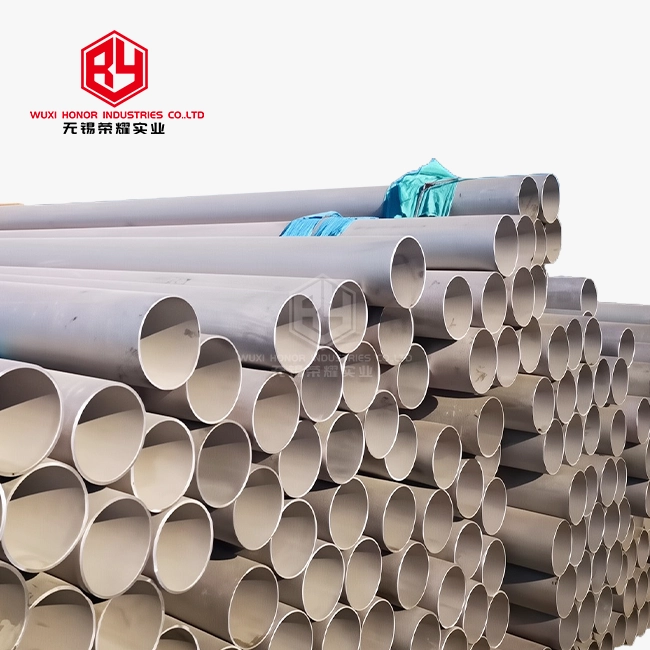

Looking for reliable industrial piping solutions? Stainless steel seamless pipe stands out as the ultimate choice for demanding applications. These precision-engineered pipes offer unmatched strength, durability, and corrosion resistance. Our comprehensive range ensures you find the perfect fit for your project needs. With over ten years of expertise serving 100+ countries worldwide, WUXI HONOR INDUSTRIES delivers quality you can trust.

Why Choose Our Seamless Stainless Steel Pipes?

Our pipes deliver superior performance where it matters most. The seamless construction eliminates weak points that plague welded alternatives. You get consistent wall thickness throughout the entire length. This uniformity translates to reliable pressure handling and extended service life.

The manufacturing process creates pipes with exceptional mechanical properties. Tensile strength exceeds standard welded options significantly. Your systems benefit from enhanced safety margins and reduced maintenance requirements. These advantages make our products ideal for critical applications.

Superior Material Properties and Standards

We maintain strict adherence to international standards. Our products comply with GB/T14976 for fluid transport applications. Boiler installations meet GB13296 requirements perfectly. International specifications like ASTM A213 and JIS G3456 are fully supported.

Quality control measures ensure consistent performance across every batch. Chemical analysis verifies material composition accuracy. Hydraulic testing confirms pressure ratings under real-world conditions. Corrosion testing validates long-term durability expectations.

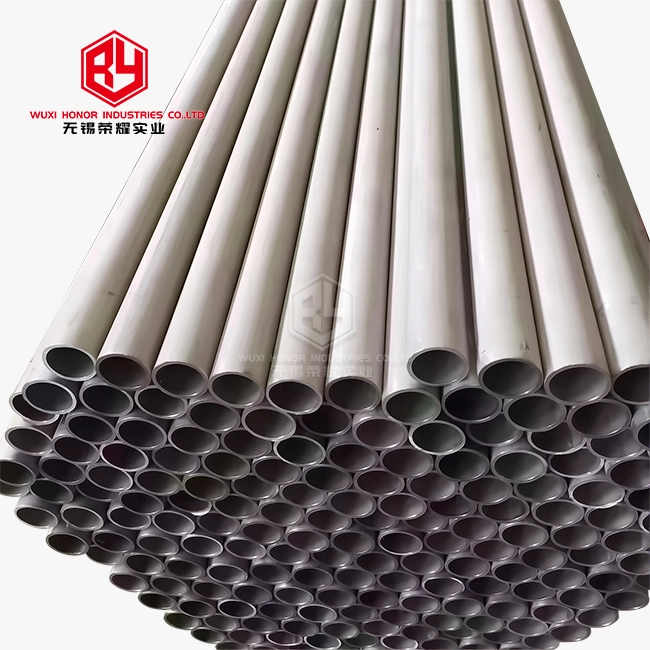

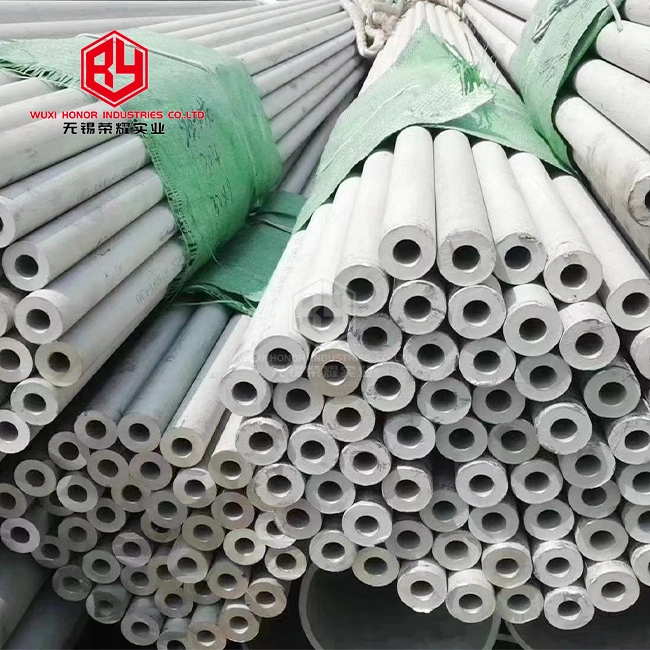

Comprehensive Size Range for Every Application

Our stainless steel seamless pipe comes in various configurations:

Hot Rolled Options:

- Diameter range: 54-480mm

- Standard lengths: 4-8 meters

- Wall thickness: 3-40mm

Cold Drawn Specifications:

- Diameter range: 6-200mm

- Precision tolerance control

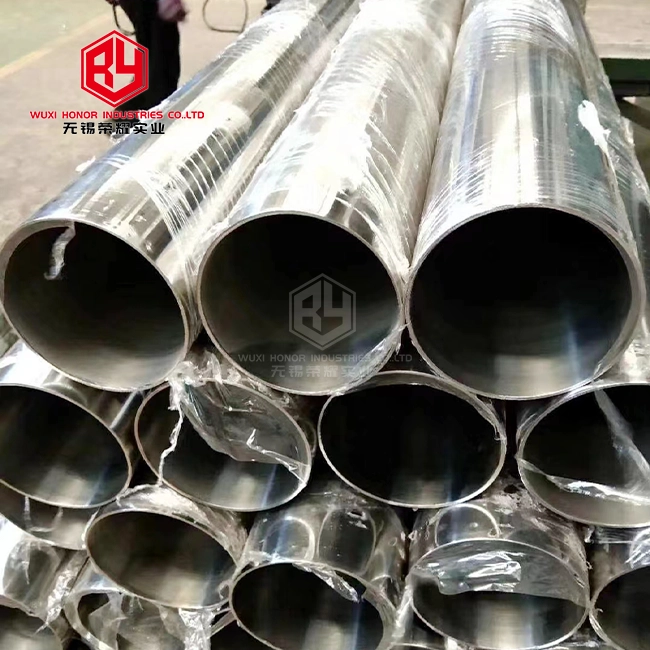

- Enhanced surface finish quality

The wall thickness directly impacts both economy and processing requirements. Thicker walls provide better cost efficiency for large-scale projects. Thinner walls suit precision applications but require specialized handling techniques.

Versatile Applications Across Industries

Building water supply systems rely on our corrosion-resistant properties. Hot water distribution networks benefit from thermal stability. High-pressure pipeline installations demand our superior strength characteristics. Mechanical structural applications appreciate the consistent material properties.

Petroleum industry projects choose our pipes for chemical compatibility. Chemical processing facilities value the contamination-free transport capabilities. Aerospace applications require our lightweight yet strong construction. These diverse uses demonstrate the versatility of our Stainless steel seamless pipe solutions.

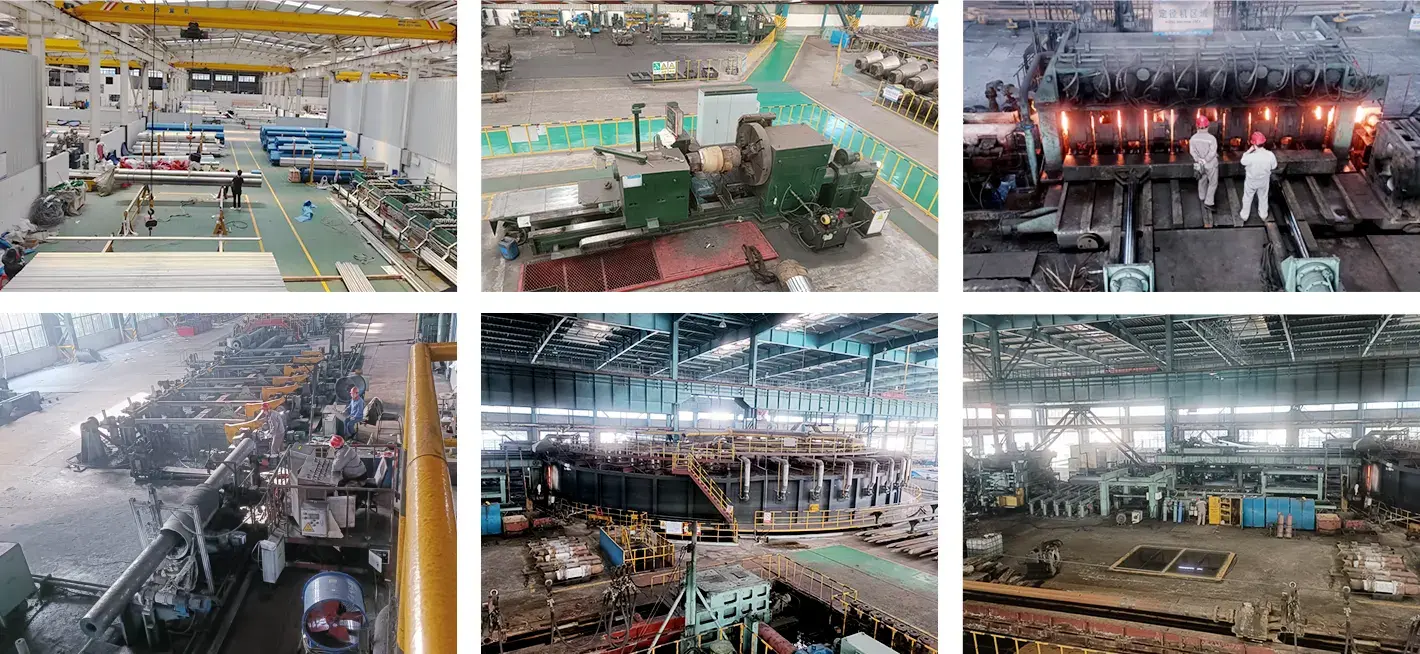

Advanced Manufacturing Process

Our production combines traditional expertise with modern technology. Hot rolling creates larger diameter options efficiently. Hot extrusion produces specialty configurations accurately. Cold drawing delivers precision dimensions consistently.

Raw material optimization reduces costs without compromising quality. Enhanced production processes improve efficiency continuously. Equipment utilization maximization ensures competitive pricing. Ongoing personnel training maintains high standards throughout operations.

Quality Assurance and Certification

ISO9001 certification backs our commitment to excellence. Every pipe undergoes rigorous testing before shipment. Surface quality inspections eliminate cracks and folding defects. Straightness measurements meet strict tolerance requirements.

Our quality control system ensures complete traceability. Documentation accompanies every order for verification purposes. Original manufacturer warranties support core product lines. These measures guarantee your investment protection.

Certificate

Global Supply Chain Excellence

Over ten years of international trade experience guides our operations. We understand customs procedures across multiple countries. Logistics partnerships ensure smooth cross-border deliveries. Multilingual support teams handle diverse customer requirements effectively.

Stable upstream relationships with premium steel mills guarantee consistent supply. Long-term partnerships enable favorable pricing structures. Quality sourcing practices maintain material standards consistently. These advantages translate to reliable service for your projects.

Exhibition

Cost-Effective Solutions

Our stainless steel seamless pipe offers excellent value through reduced maintenance costs. Extended service life minimizes replacement frequency. Superior pressure ratings allow system optimization. Corrosion resistance eliminates costly downtime incidents.

Bulk ordering options provide additional savings opportunities. Flexible payment terms accommodate various budget requirements. Competitive pricing reflects our efficient operations. These factors combine to deliver exceptional total cost of ownership.

Technical Support and Service

Our experienced team provides comprehensive technical assistance. Application guidance ensures optimal product selection. Installation support minimizes project delays. Ongoing consultation addresses operational questions promptly.

Rapid response times characterize our customer service approach. Detailed quotations include all relevant specifications. Order tracking keeps you informed throughout delivery. Post-delivery support maintains long-term relationships successfully.

Partner with Industry Leaders

Ready to experience superior piping solutions? Our stainless steel seamless pipe products combine proven performance with competitive pricing. Contact our expert team at admin@rongyaopipe.com today. We'll help you find the perfect solution for your specific requirements and ensure successful project completion.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!