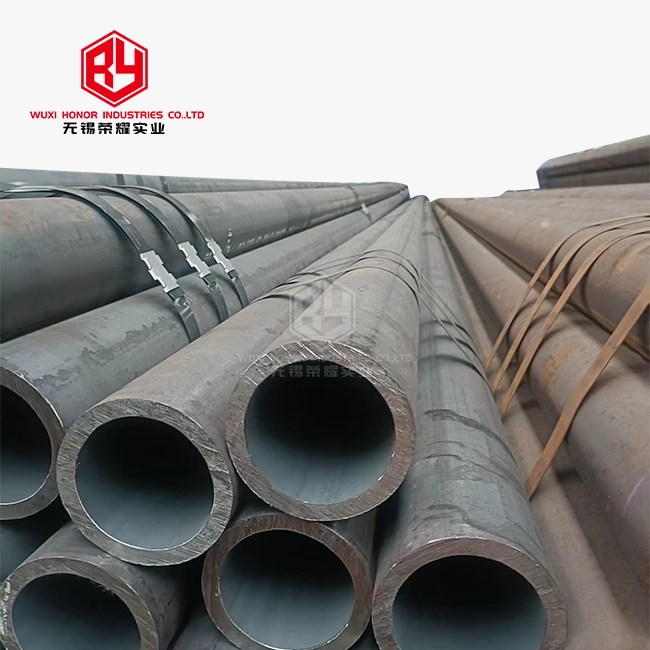

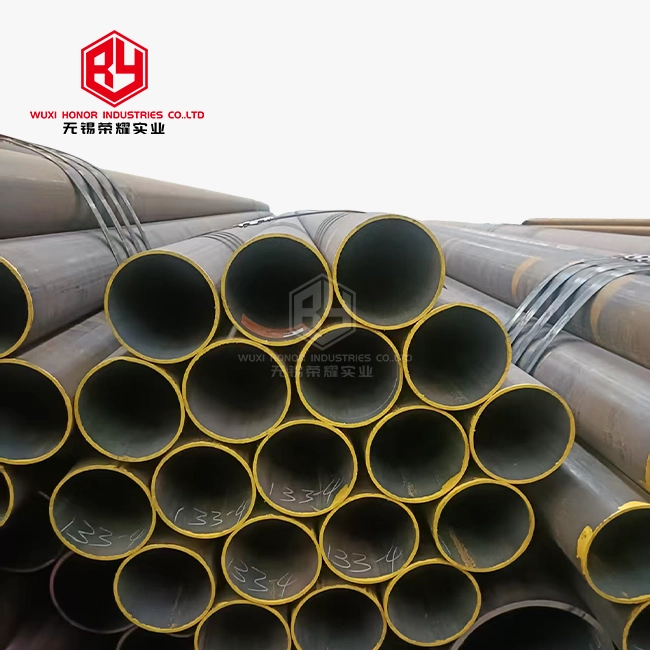

High Pressure Boiler Tube

Its manufacturing adopts precision rolling technology, develops high-end products such as Cr Mo alloy pipes and duplex stainless steel pipes, and applies inner wall coating technology to enhance corrosion resistance. The chemical composition inspection follows the GB222-84 and GB223 standards, and the physical properties include tensile and hydraulic tests. . It is expected that the demand for thermal power will remain at 700000 tons by 2025, and the demand in the chemical industry will reach 400000 tons. The product specifications cover hot-rolled tubes with an outer diameter of 22-530mm and cold drawn tubes with an outer diameter of 10-108mm. The steel grades include carbon structural steel such as 20G and 15CrMoG, as well as alloy structural steel.

Our company's products have obtained ISO9001 certification, ensuring product quality

High Pressure Boiler Tube - Premium Quality Steel Pipes for Industrial Applications

When your control era or mechanical forms request dependable execution beneath extraordinary conditions, choosing the right high pressure boiler tube gets to be basic. At WUXI HONOR Businesses CO.LTD, we make consistent steel channels particularly outlined for high-temperature, high-pressure evaporator frameworks. Our tubes meet exacting GB/T 5310-2023 national measures and convey extraordinary strength over warm control, chemical, and metallurgical businesses. With over ten a long time of encounter serving clients in 100+ nations, we get it your require for quality and reliability.

Why Choose Our Boiler Tubes for Your Industrial Needs

Superior Material Composition and Construction

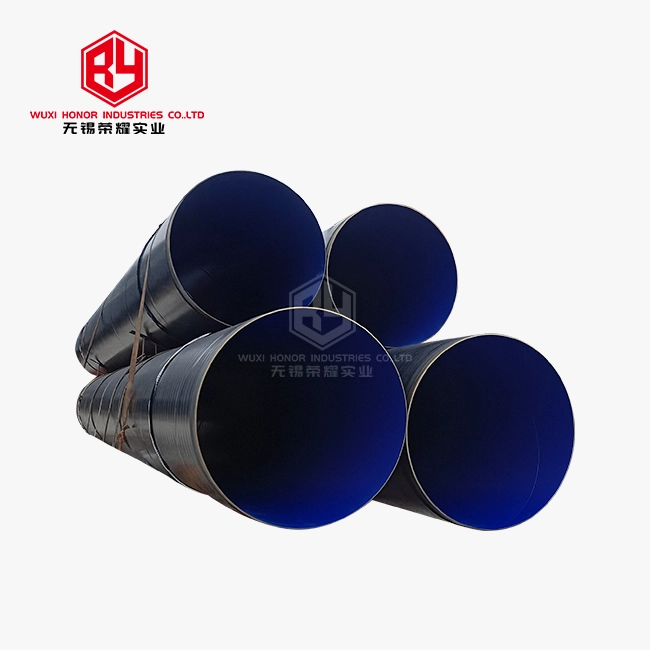

Our consistent steel channels utilize premium amalgam materials counting chromium-molybdenum steel and austenitic stainless steel. These materials give extraordinary resistance to oxidation and erosion. You get tubes that keep up auxiliary keenness indeed when uncovered to high-temperature pipe gasses and pressurized steam environments.

The accuracy rolling innovation we utilize guarantees uniform divider thickness all through each tube. This consistency deciphers to dependable execution and amplified benefit life for your evaporator systems.

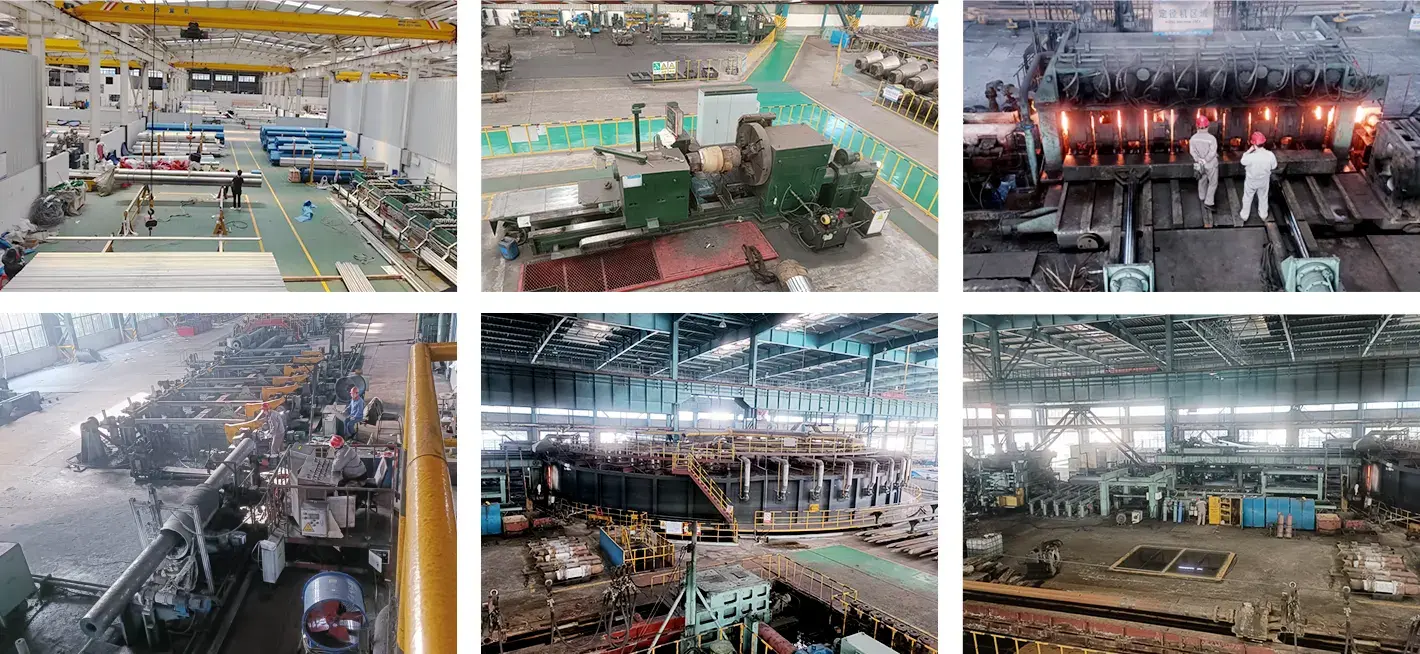

Advanced Manufacturing Process

We offer both hot-rolled and cold-drawn manufacturing options to meet your specific requirements:

Hot-Rolled Specifications:

- Outer diameter range: 22-530mm

- Ideal for larger boiler applications

- Excellent for high-volume steam generation

Cold-Drawn Specifications:

- Outer diameter range: 10-108mm

- Perfect for precision applications

- Enhanced surface finish and dimensional accuracy

Technical Excellence You Can Trust

Our manufacturing process includes comprehensive quality control measures. Each tube undergoes rigorous chemical composition testing following GB222-84 and GB223 standards. Physical property testing includes tensile strength and hydraulic pressure tests to ensure your tubes meet operational demands.

The smooth inner wall design reduces fluid resistance and minimizes scaling buildup. This feature helps maintain efficient heat transfer while reducing maintenance requirements.

Applications Across Multiple Industries

Power Generation Sector

Thermal power plants rely on our high pressure boiler tube for critical components. Industry data shows that every 1GW increase in installed capacity requires approximately 8,000 tons of high-pressure boiler tubes. Our products support this growing demand with consistent quality and reliable supply.

Chemical Processing Industry

Chemical plants working beneath extraordinary conditions require tubes that stand up to erosion and keep up auxiliary astuteness. Our inward divider coating innovation gives improved assurance against forceful chemicals and high-temperature processes.

Metallurgical Applications

Steel plants and metal preparing offices believe our tubes for their high-temperature heater applications. The combination of warm resistance and auxiliary soundness makes our items perfect for these requesting environments.

Global Supply Chain Advantage

With over a decade of universal exchange encounter, we get it your calculated challenges. Our set up supply organize guarantees opportune conveyance to your area, notwithstanding of geological imperatives. We keep up solid associations with quality steel plants around the world, ensuring reliable fabric availability.

Our multilingual client benefit group gives bolster all through the requesting handle. From beginning request to last conveyance, you get personalized consideration that addresses your particular requirements.

Exhibition

Quality Assurance and Standards Compliance

Every Tall Weight Evaporator Tube we fabricate experiences strict quality control methods. Our ISO9001 certification illustrates our commitment to keeping up universal quality guidelines. You get items with full traceability documentation, guaranteeing compliance with your venture specifications.

We hone long-term trade connections built on believe and unwavering quality. This approach has earned us acknowledgment as a favored provider among worldwide mechanical customers.

Certificate

Technical Support and Customization

Understanding that diverse applications require particular arrangements, we offer customized fabricating alternatives. Our specialized group works with you to decide ideal steel grades and determinations for your specific working conditions.

Available steel grades include:

- Carbon structural steel (20G series)

- Alloy structural steel (15CrMoG series)

- Specialized chromium-molybdenum alloys

- Duplex stainless steel options

Get Started Today

Ready to enhance your boiler system performance with premium quality tubes? Our team stands ready to discuss your specific requirements and provide detailed quotations. Contact us at admin@rongyaopipe.com for technical specifications, pricing information, or to place your order. Experience the difference that quality high pressure boiler tube products make in your industrial operations.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!

Seamless Steel Pipe.webp)