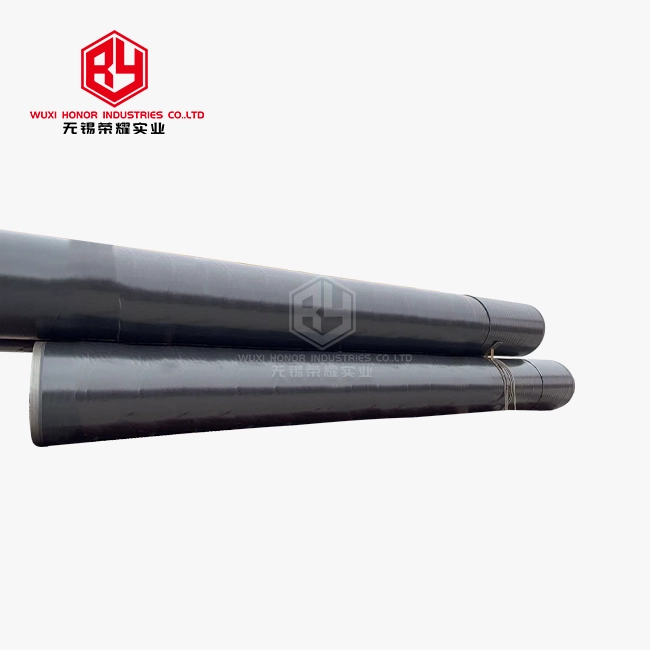

Cold Drawn Seamless Steel Pipe

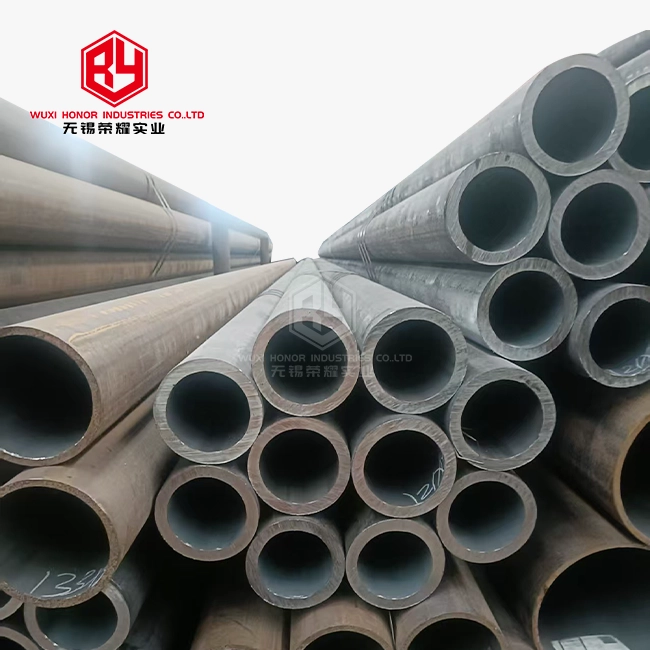

Cold rolling is usually carried out on a two roll mill, where steel pipes are rolled in a circular hole pattern consisting of a variable cross-section circular groove and a stationary conical top. Cold drawing is usually carried out on single chain or double chain cold drawing machines with a capacity of 0.5-100T. High quality carbon structural steel cold drawn seamless pipes are mainly made of 10 #, 20 #, 35 #, and 45 # steel. In addition to ensuring chemical composition and mechanical properties, water pressure tests, edge rolling, expansion, flattening, and other tests must be conducted.

The weight calculation formula for cold drawn seamless steel pipes is: (outer diameter wall thickness) * wall thickness * 0.02466=kg/meter (weight per meter)

Our company's products have obtained ISO9001 certification, ensuring product quality

Cold Drawn Seamless Steel Pipe - Precision Engineering Solution

High-Performance Cold Drawn Seamless Steel Pipe for Industrial Applications

When you require accuracy designing arrangements, cold drawn seamless steel pipe conveys unmatched execution. This high-quality steel item combines predominant dimensional exactness with fabulous mechanical properties. You get dependable materials that meet the requesting necessities of advanced mechanical applications. Our channels experience thorough cold drawing forms to guarantee steady quality and execution over each clump you order.

What Makes Our Precision Seamless Pipes Special?

Superior Dimensional Control

Our exactness consistent channels offer uncommon dimensional exactness that outperforms conventional hot-rolled choices. You advantage from controlled resiliences in external distance across, inward distance across, and divider thickness. This exactness dispenses with exorbitant auxiliary machining operations. Your ventures move forward speedier with materials prepared for prompt utilize.

Enhanced Mechanical Properties

Cold drawing creates work-hardening effects that significantly boost performance. You receive pipes with improved tensile strength, yield strength, and hardness levels. The process maintains excellent toughness while delivering structural stability. Your applications handle moderate to heavy loads with confidence.

Versatile Material Options

We manufacture seamless pipes using high-quality carbon structural steel grades including 10#, 20#, 35#, and 45# steel. Each grade offers specific advantages for different applications. You choose the perfect material match for your project requirements.

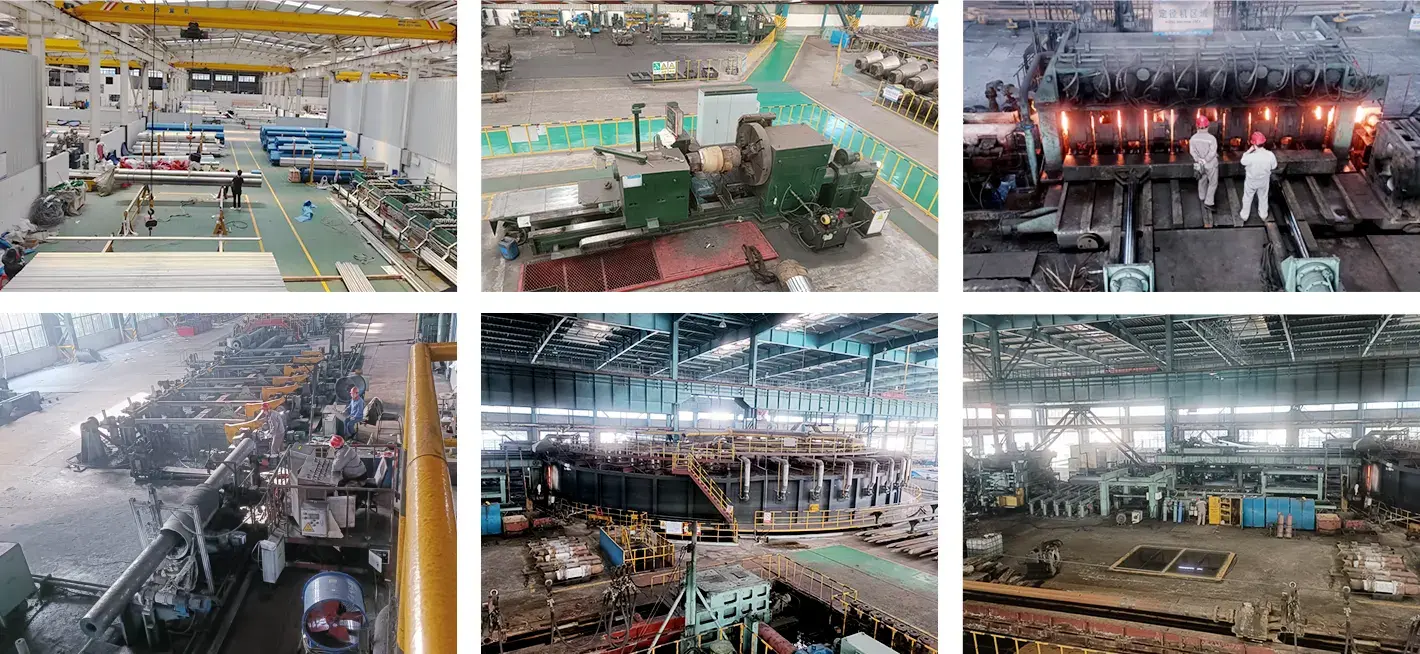

Manufacturing Excellence You Can Trust

Rigorous Quality Testing

Every pipe undergoes comprehensive testing including water pressure tests, edge rolling, expansion, and flattening evaluations. We verify chemical composition and mechanical properties meet specifications. Your orders arrive with complete quality documentation and traceability.

ISO9001 Certified Production

Our manufacturing facility maintains ISO9001 certification, ensuring consistent quality management throughout production. You work with a supplier committed to international quality standards. This certification reflects our dedication to continuous improvement and customer satisfaction.

Applications Across Multiple Industries

Mechanical Structure Manufacturing

Precision seamless pipes excel in mechanical structure applications where dimensional accuracy matters. You achieve better material utilization and reduced machining time. Component fit and finish improve significantly compared to standard steel pipe alternatives.

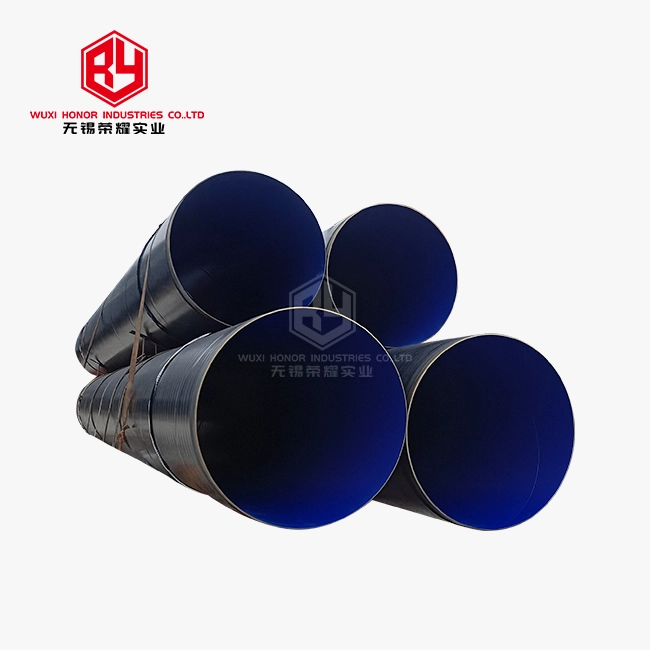

Hydraulic Equipment Systems

Hydraulic applications demand reliable pressure containment and smooth internal surfaces. Our cold drawn seamless steel pipe deliver both requirements effectively. You get leak-free connections and optimal fluid flow characteristics for hydraulic system performance.

Petrochemical Processing

Chemical processing environments require corrosion resistance and structural integrity. Seamless construction eliminates weak points common in welded alternatives. Your installations operate safely under demanding chemical exposure conditions.

Streamlined Ordering and Global Delivery

Comprehensive Product Portfolio

WUXI HONOR INDUSTRIES CO.LTD offers complete metal material solutions beyond seamless pipes. We supply carbon steel, stainless steel, copper, and aluminum products. You consolidate purchasing through one trusted supplier relationship.

Proven International Experience

With over ten years serving customers in 100+ countries, we understand global trade requirements. Our team navigates customs procedures and logistics efficiently. You receive materials on schedule regardless of your location.

Flexible Order Processing

We accommodate both standard specifications and custom requirements. Our engineering team works with you to develop solutions matching specific application needs. Quick response times keep your projects moving forward.

Technical Specifications and Calculations

Understanding pipe specifications helps you make informed decisions. Our weight calculation formula provides accurate material estimates: (outer diameter - wall thickness) × wall thickness × 0.02466 = kg/meter. This formula helps you calculate shipping costs and structural load requirements accurately.

Manufacturing processes include both cold rolling and cold drawing techniques. Cold rolling uses two-roll mills with variable cross-section patterns. Cold drawing employs single or double chain machines with 0.5-100T capacity ranges. These processes ensure consistent quality and dimensional control.

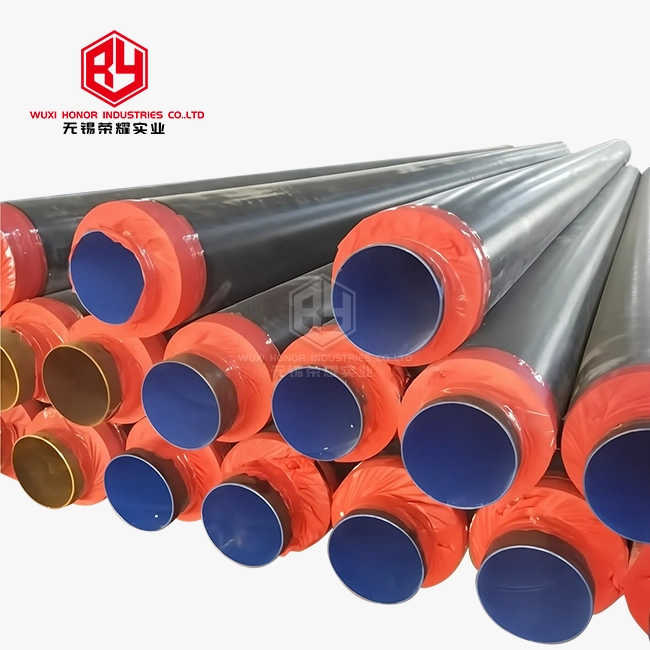

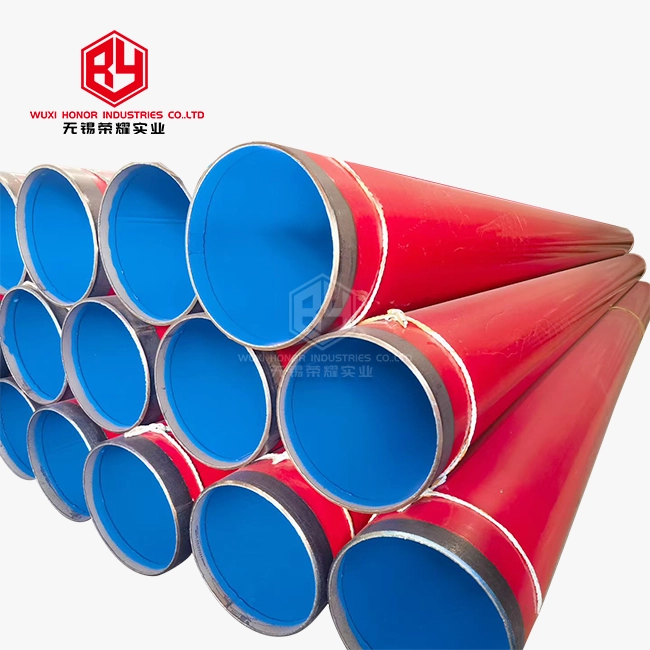

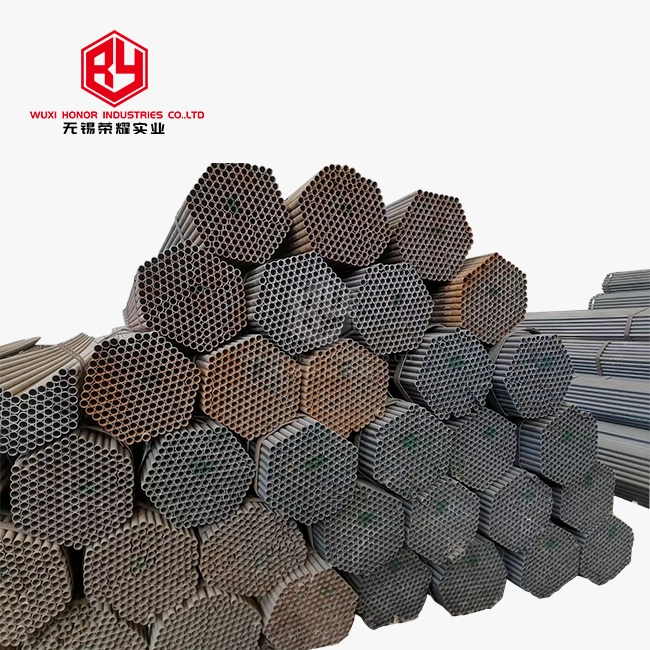

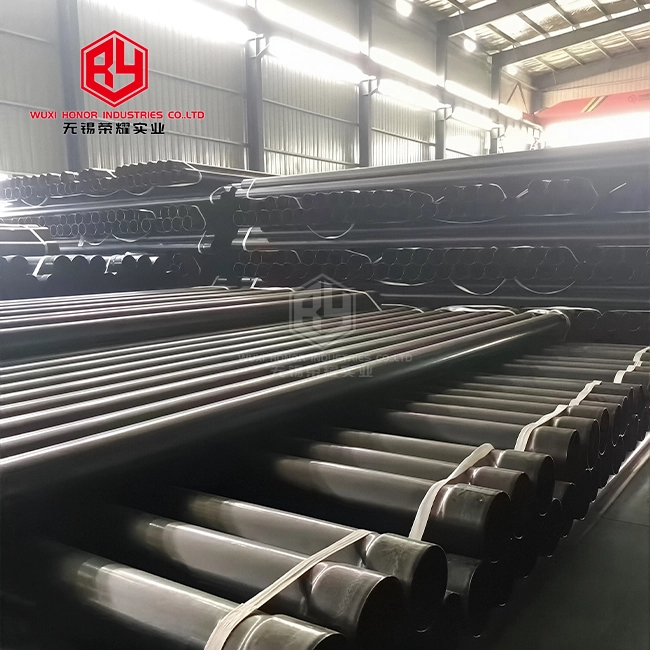

Exhibition

Partner with Experience and Reliability

When you choose our cold drawn seamless steel pipe, you partner with proven industry expertise. Our decade-plus experience in international metal trade ensures smooth transactions. Quality management systems guarantee product consistency. Global supply networks provide reliable delivery schedules.

Ready to discuss your seamless pipe requirements? Contact our technical team at admin@rongyaopipe.com for detailed specifications and pricing information today.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!