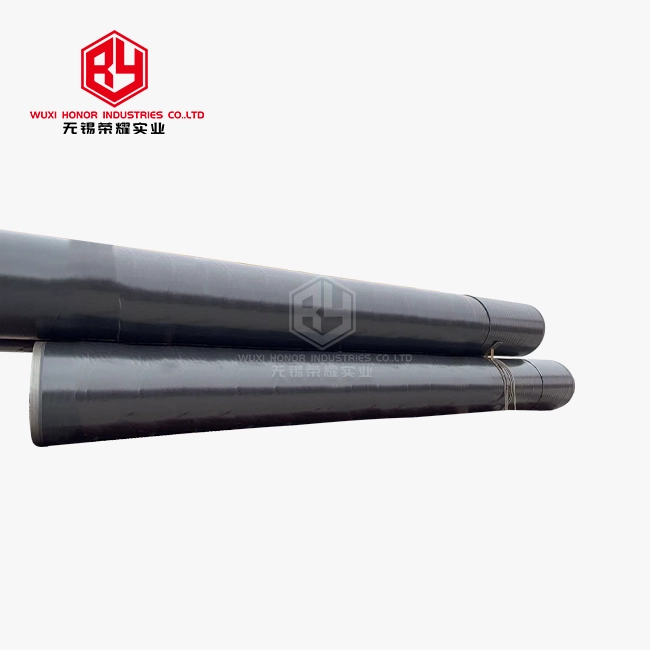

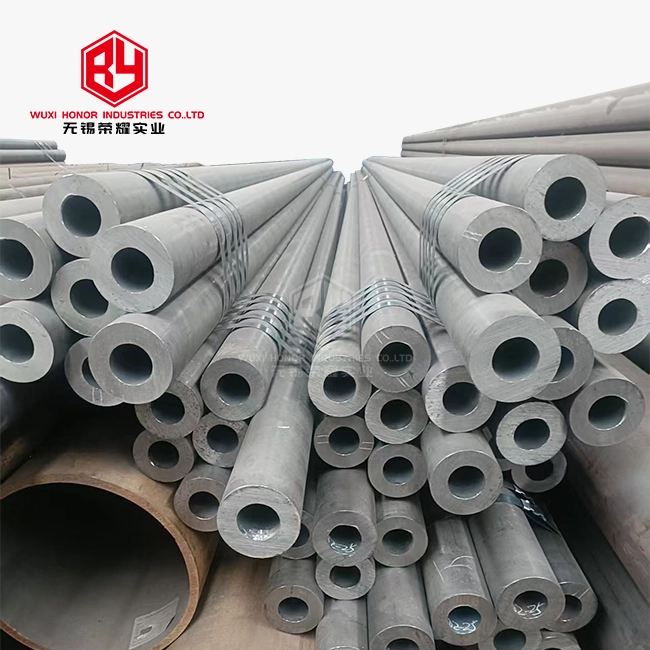

Precision Steel Pipe

The steel pipes have no cracks when expanded or flattened, and do not deform during cold bending. They can withstand high pressure and undergo various complex deformations and mechanical deep processing treatments.

Our company's products have obtained ISO9001 certification, ensuring product quality

Precision Steel Pipe: High-Quality Solutions for Industrial Applications

When your project demands exact specifications and superior performance, our product delivers the reliability you need. Manufactured through advanced cold drawing and hot rolling processes, these pipes offer exceptional dimensional accuracy and surface quality. With no oxide layers on inner or outer walls and superior pressure resistance, precision steel pipes provide the foundation for critical industrial components. Our decade of expertise ensures you receive products that meet international standards and exceed expectations.

Superior Engineering for Demanding Applications

Our products excel where ordinary pipes fail. The manufacturing process eliminates surface defects while maintaining strict dimensional tolerances. You get smooth inner and outer walls without requiring additional finishing work.

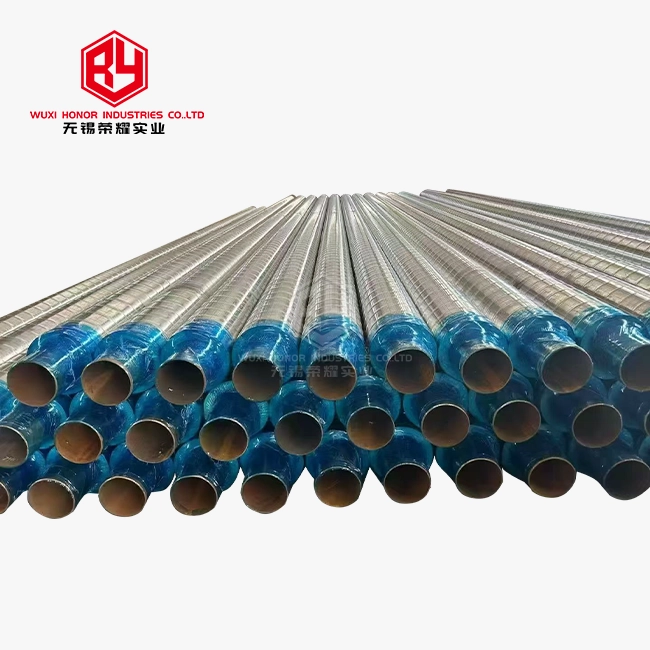

These pipes resist deformation during cold bending operations. They maintain structural integrity under high-pressure conditions. The absence of oxide films means better corrosion resistance and longer service life.

Exceptional Dimensional Accuracy

Your projects require exact measurements, and our pipes deliver them consistently. Through controlled cold drawing processes, we achieve dimensional tolerances superior to standard steel pipes. Outer diameter, inner diameter, and wall thickness variations stay within tight ranges.

This accuracy reduces your machining time and material waste. You can integrate these components directly into assemblies without extensive modifications. The consistent dimensions across batches ensure reliable performance in production environments.

Versatile Applications Across Industries

Manufacturing sectors rely on these pipes for hydraulic and pneumatic systems. Cylinder applications benefit from the smooth bore surfaces and pressure resistance. Oil cylinder production uses these pipes for their reliability and precision.

Construction projects incorporate them where structural integrity matters most. Machinery manufacturers choose them for critical load-bearing components. The versatility extends to petrochemical applications where corrosion resistance is essential.

Advanced Manufacturing Process

Our manufacturing combines traditional techniques with modern precision control. Cold drawing operations create the smooth surface finish you need. Hot rolling processes ensure uniform material properties throughout each pipe.

Heat treatment eliminates internal stresses while maintaining strength characteristics. Quality control measures verify dimensions at multiple production stages. Each batch undergoes thorough testing before shipment.

Global Supply Chain Excellence

With over ten years in international trade, we understand your logistics needs. Our supply network spans more than 100 countries worldwide. We handle customs procedures and documentation efficiently.

Partnerships with premium steel mills ensure consistent material quality. Our inventory management keeps common specifications readily available. Custom orders receive priority attention for faster delivery.

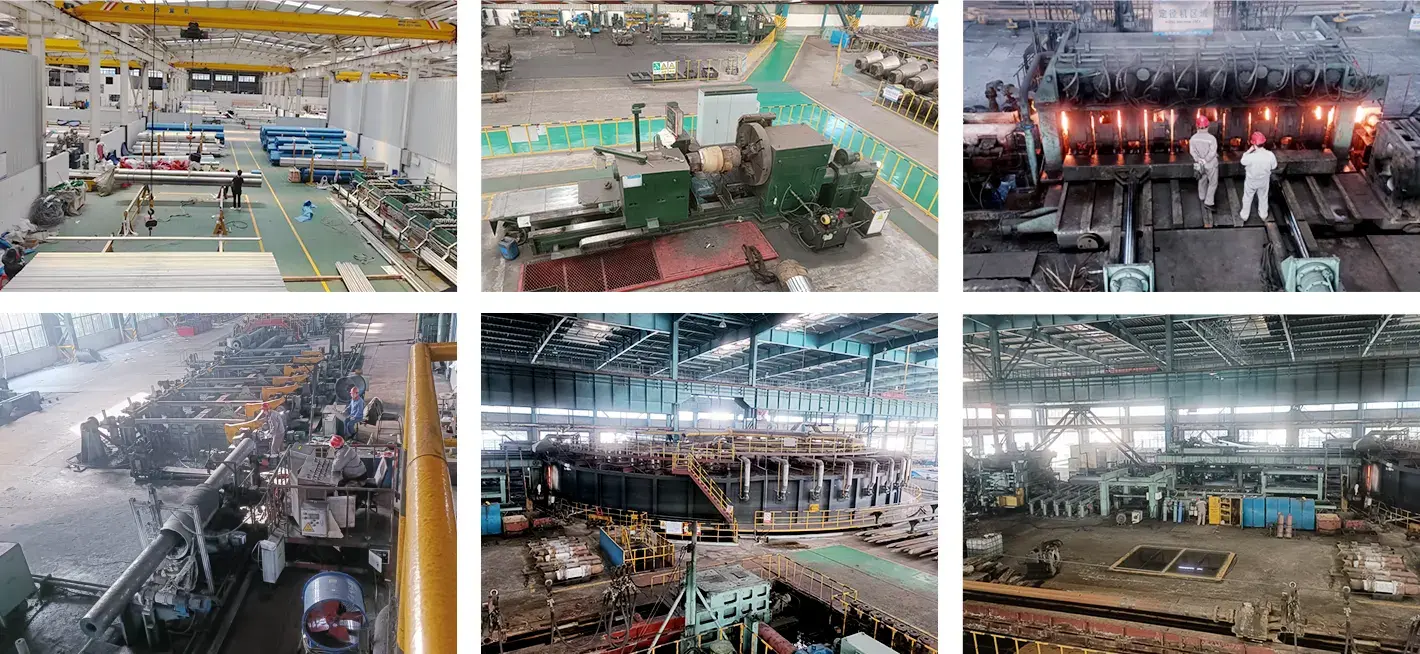

Factory

Quality Assurance You Can Trust

ISO9001 certification validates our quality management systems. Each precision steel pipes batch includes detailed material certifications. Traceability documentation supports your quality requirements.

Our testing facilities verify mechanical properties and dimensional accuracy. Surface quality inspections ensure defect-free delivery. Performance testing confirms pressure ratings and durability specifications.

Certificate

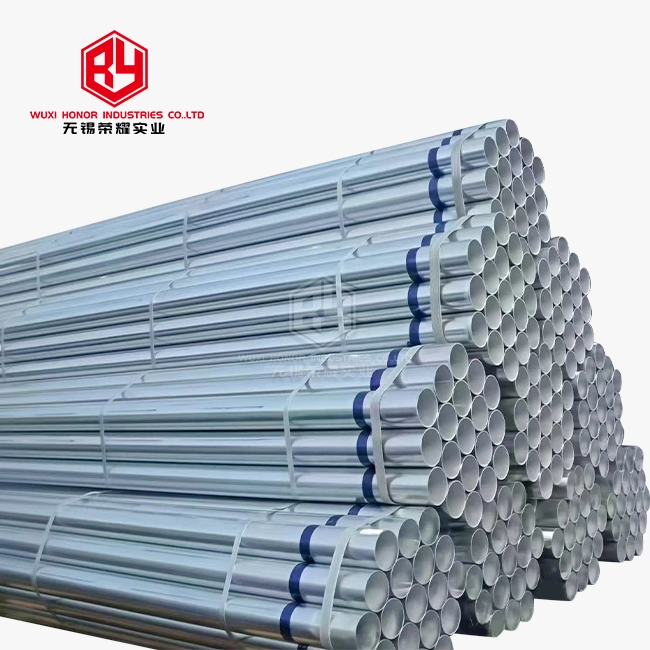

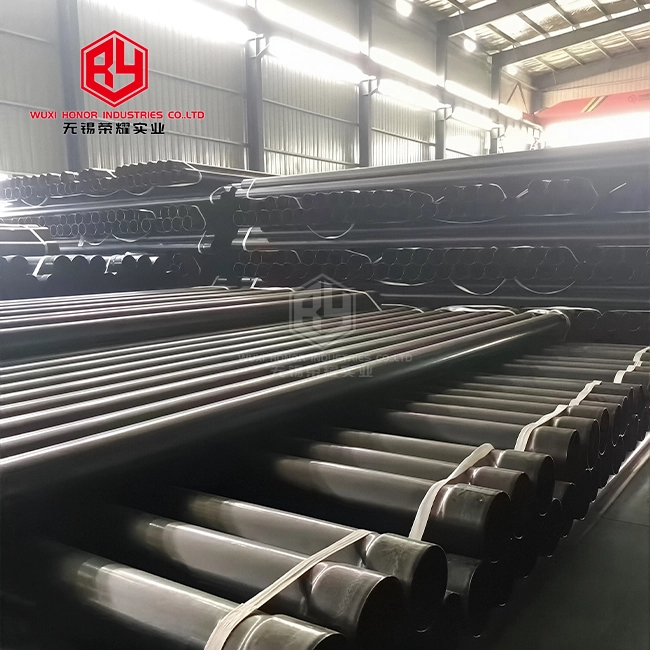

Seamless or Welded Options

Choose from seamless construction for maximum strength applications. Welded options provide cost-effective solutions for standard requirements. Both types maintain the precision characteristics you expect.

Seamless pipes offer superior pressure resistance for critical applications. Welded versions provide excellent value while maintaining quality standards. Our technical team helps you select the optimal configuration.

Technical Support and Customization

Our engineering team provides technical guidance for your specific applications. Custom dimensions and specifications are available for unique requirements. Material selection assistance ensures optimal performance characteristics.

We offer application-specific recommendations based on operating conditions. Installation guidance helps maximize component performance. Ongoing support maintains your satisfaction throughout the project lifecycle.

Exhibition

Efficient Order Processing

From initial inquiry to final delivery, our streamlined process saves you time. Competitive quotations arrive quickly with detailed specifications. Order tracking keeps you informed throughout production.

Flexible packaging options protect your investment during shipping. Multiple shipping methods accommodate your schedule requirements. Documentation packages include all necessary certifications and test reports.

Ready to enhance your next project with superior precision steel pipes solutions? Contact our experienced team at admin@rongyaopipe.com for personalized assistance and competitive pricing tailored to your specific requirements.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!

Seamless Steel Pipe.webp)