Insulated Steel Pipe

Premium Insulated Steel Pipe Solutions for Your Industrial Needs

When you require solid pipeline arrangements that keep up temperature control whereas guaranteeing strength, our insulated steel pipe frameworks convey uncommon execution. At WUXI HONOR Businesses CO.LTD, we've went through over a decade idealizing these progressed pipeline items to serve your mechanical, development, and vitality extend prerequisites. Our protects steel channels combine predominant warm productivity with strong development, making them the perfect choice for applications requiring temperature-sensitive liquid transport over differing mechanical sectors.

What Makes Our Insulated Steel Pipes Special?

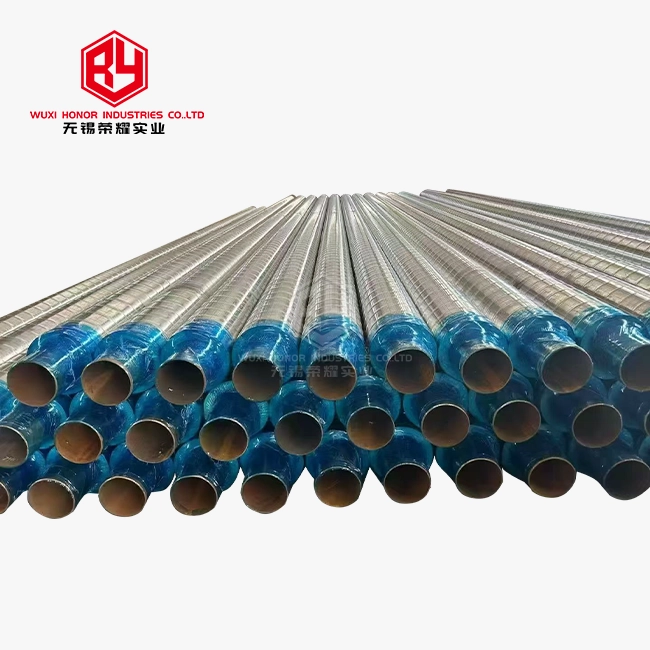

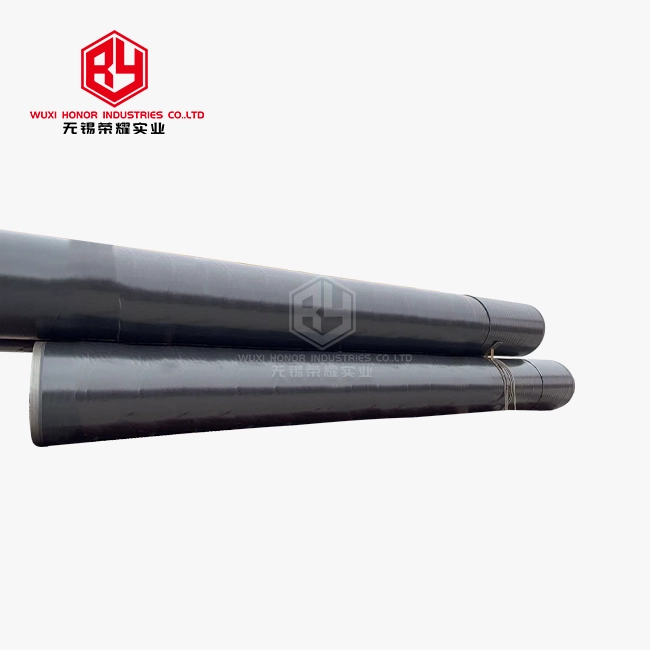

Our protects steel channels include a modern multi-layer plan that sets them separated from standard pipeline arrangements. The center steel pipe gives auxiliary quality and liquid transport capabilities. We at that point apply specialized separator materials like polyurethane froth or shake fleece as the center layer.

This cover layer significantly diminishes warm conductivity. Your warmed or cooled liquids keep up their target temperatures all through transport. The external defensive layer shields against natural harm, erosion, and mechanical stress.

This coordinates "transportation + cover + security" plan implies you get three basic capacities in one item. You spare establishment time, decrease support needs, and accomplish superior long-term execution compared to independently introduced components.

Superior Thermal Performance You Can Trust

The warm proficiency of our Protects Steel Pipe items comes from carefully chosen cover materials. Polyurethane froth offers fabulous warm resistance with negligible thickness necessities. Shake fleece gives extraordinary fire resistance whereas keeping up warm performance.

Both materials make an successful boundary against warm exchange. Your hot water frameworks remain hot. Your chilled liquid frameworks keep up their cool temperatures. This warm solidness diminishes vitality utilization significantly.

You'll take note prompt investment funds in warming and cooling costs. Over time, these vitality reserve funds frequently counterbalanced the beginning venture in quality protects channeling systems.

Built for Challenging Environments

Industrial applications request pipeline frameworks that withstand cruel conditions. Our channels include defensive external layers outlined for toughness. Polyethylene external casings stand up to dampness, soil chemicals, and physical impacts.

Anti-corrosion coatings give extra security in chemically forceful situations. This multi-layer assurance guarantees your pipeline venture endures for decades with negligible support requirements.

Underground establishments advantage from the moisture-resistant properties. Above-ground applications appreciate the UV resistance and climate assurance built into our defensive systems.

Versatile Applications Across Industries

Construction ventures depend on our protects channeling for locale warming frameworks and HVAC applications. Fabricating offices utilize them for prepare liquid transport where temperature control is critical.

Petrochemical plants appreciate the combination of warm execution and chemical resistance. Control era offices depend on our insulated steel pipe for steam and condensate systems.

Food handling operations advantage from the sterile plan alternatives and temperature support capabilities. Each application exhibits the flexibility and unwavering quality of our Protects Steel Pipe arrangements.

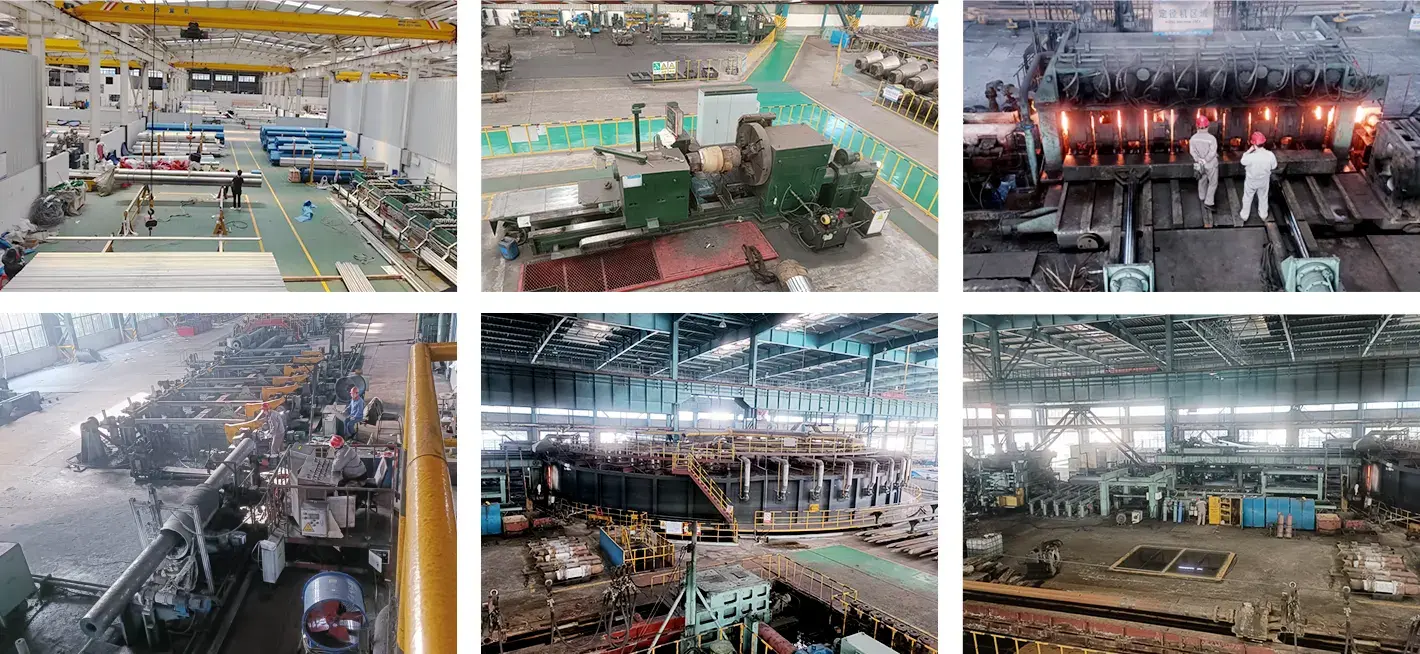

Quality Assurance and Global Expertise

Our ISO9001 certification reflects our commitment to consistent quality standards. Every pipe undergoes rigorous testing before shipment. We verify thermal performance, structural integrity, and protective layer adhesion.

With over ten years of international experience serving 100+ countries, we understand diverse project requirements. Our team provides technical support throughout your project lifecycle.

We've built relationships with premium steel mills worldwide. This supply chain expertise ensures you receive materials that meet or exceed international standards for your specific application requirements.

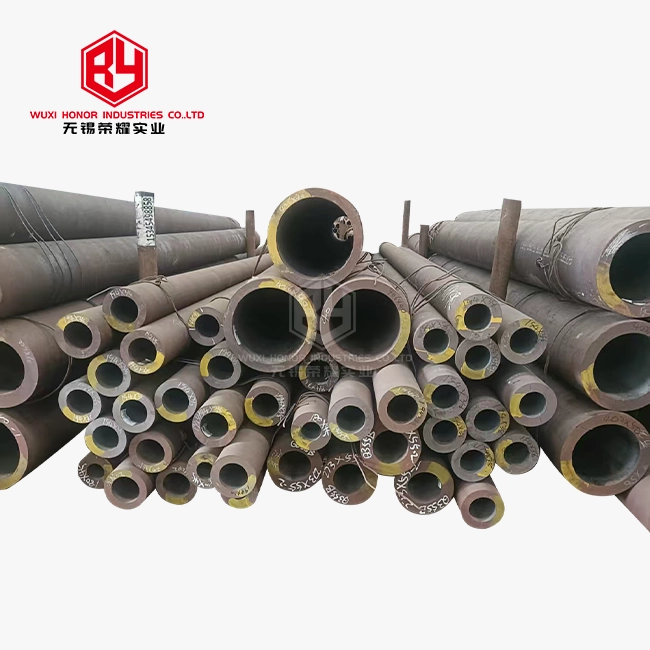

Exhibition

Professional Support and Custom Solutions

Every project has unique requirements. Our engineering team works with you to specify the optimal insulation thickness, protective systems, and connection methods for your application.

We provide detailed technical documentation, installation guidelines, and ongoing support. Our global experience means we understand local codes and standards wherever your project is located.

Custom sizes, special coatings, and unique configurations are available to meet your specific project needs.

Ready to upgrade your pipeline system with premium insulated steel pipe solutions? Contact our technical team at admin@rongyaopipe.com for detailed specifications and project consultation.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!

Seamless Steel Pipe.webp)