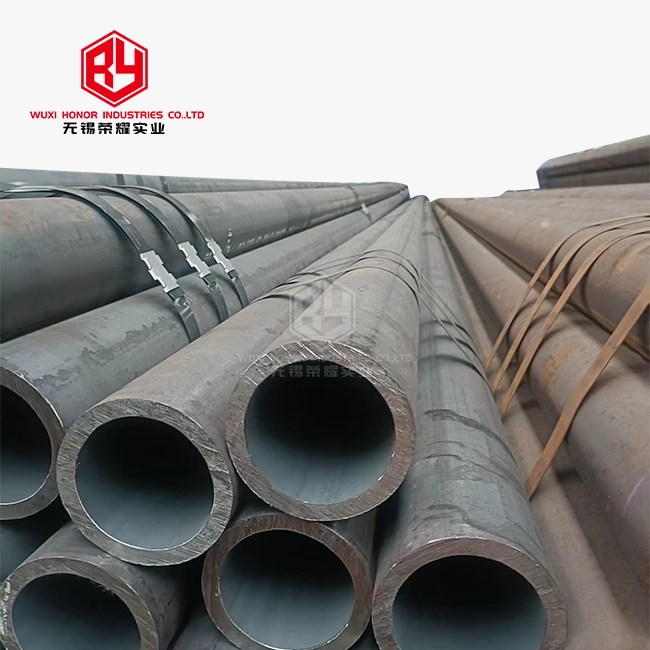

15Crmog Alloy Steel Pipe

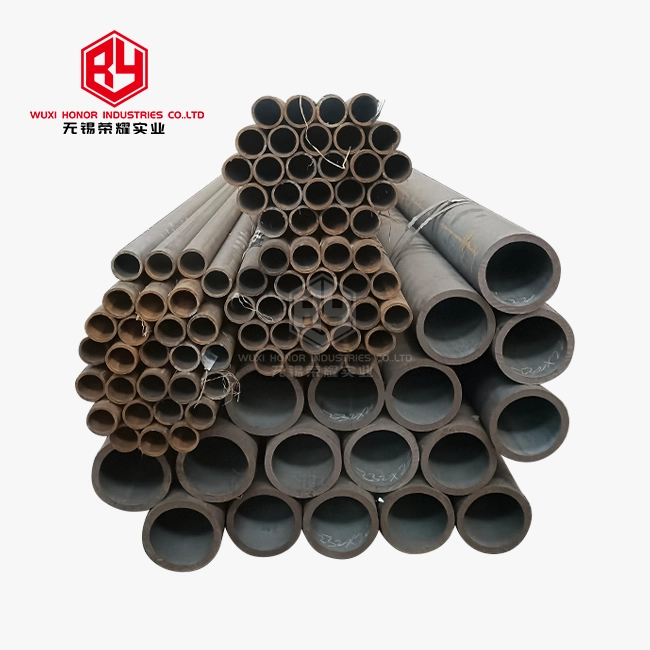

This pipe meets the GB5310-2008 standard and has a thermal strength and oxidation resistance of over 440MPa. It can effectively resist hydrogen corrosion in high temperature environments, but its weldability is poor and requires special processing. The production process is divided into two categories: hot rolling and cold drawing. The hot rolling process includes heating the tube blank, perforation forming, and sizing cooling; The cold drawing process requires annealing, acid washing, and multiple cold processing steps.

Its specifications cover more than ten national standards such as structural pipes, fluid transport pipes, boiler pipes, etc., involving multiple fields such as ships, petroleum, and chemical engineering. Preheating measures and specialized welding materials should be used during welding. After welding, a high-temperature tempering treatment at 715 ℃ is required to ensure the performance of the joint.

The heating and cooling rate should be precisely controlled during the heat treatment process. The allowable deviation of the outer diameter of the pipe is divided into four levels, D1-D4, with a maximum accuracy of ± 0.5% tolerance zone.

Our company's products have obtained ISO9001 certification, ensuring product quality

15CrMoG Alloy Steel Pipe - High-Performance Solution for Critical Applications

Looking for a solid steel pipe arrangement that can handle extraordinary conditions? Our 15CrMoG alloy steel pipe conveys extraordinary execution in high-temperature, high-pressure situations. This premium chromium-molybdenum amalgam steel pipe is particularly built for control plants, atomic offices, and basic mechanical applications. With over ten a long time of involvement serving clients over 100+ nations, WUXI HONOR Businesses CO.LTD gives you with demonstrated quality and tried and true service.

What Makes 15CrMoG Alloy Steel Pipe Special?

This specialized combination steel pipe has a place to the pearlite heat-resistant steel family. The special chromium-molybdenum composition gives it exceptional properties that standard channels essentially cannot match.

You get warm quality surpassing 440MPa and extraordinary oxidation resistance. The pipe works dependably in temperatures up to 550℃ without losing its basic astuteness. This makes it culminate for your most requesting applications.

The fabric successfully stands up to hydrogen erosion in extraordinary situations. Your frameworks remain ensured indeed beneath the harshest working conditions.

Superior Performance Features

Exceptional High-Temperature Resistance

Your operations advantage from our pipe's capacity to keep up steadiness in extraordinary warm. The chromium and molybdenum augmentations make a vigorous combination that won't distort or oxidize effectively at lifted temperatures.

Outstanding Mechanical Properties

You get adjusted malleable quality, abdicate quality, and durability in each pipe. Indeed at tall temperatures, the fabric keeps up fabulous crawl quality and perseverance properties.

The pipe withstands tall weight and complex push designs. You can tally on its auxiliary solidness for long-term, dependable benefit.

Precise Manufacturing Standards

Our 15CrMoG alloy steel pipe meets GB5310-2008 standards. You get consistent quality with outer diameter tolerances ranging from D1 to D4 grades, with maximum accuracy of ±0.5%.

We offer both hot-rolled and cold-drawn production options. This gives you flexibility to choose the manufacturing process that best suits your specific requirements.

Certificate

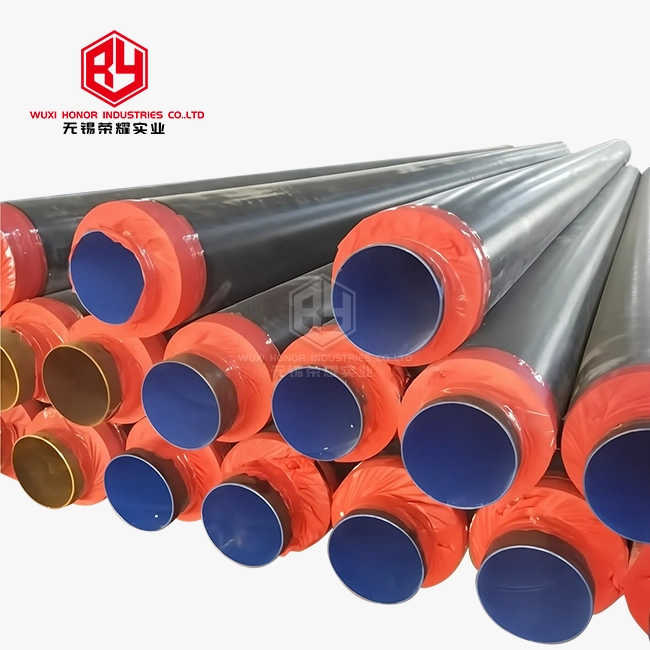

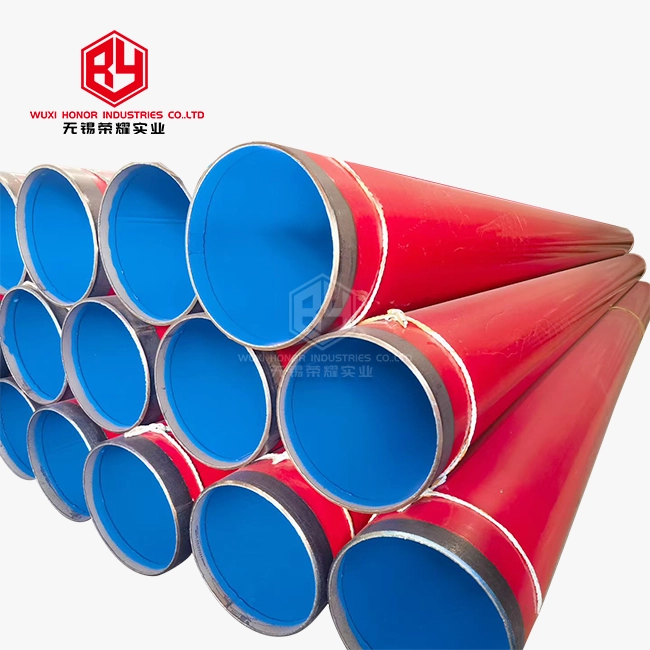

Wide Range of Applications

Your projects across multiple industries can benefit from this versatile pipe:

- Power plant boiler systems

- Nuclear power facility components

- Petrochemical processing equipment

- High-pressure fluid transportation

- Marine engineering applications

- Industrial heating systems

The pipe covers specifications for structural applications, fluid transport, and boiler installations. You get one solution for diverse engineering needs.

Professional Processing and Installation

Working with this alloy requires specialized knowledge. The material has specific welding requirements that our technical team understands completely.

Preheating and specialized welding materials ensure proper joint formation. Post-welding heat treatment at 715℃ optimizes the connection's performance characteristics.

We control heating and cooling rates precisely during manufacturing. This attention to detail ensures you receive pipes that meet the highest quality standards.

Quality You Can Trust

Our ISO9001 certification demonstrates our commitment to consistent quality. You receive products manufactured under strict quality control processes with full traceability.

We maintain long-term partnerships with premium steel mills worldwide. This ensures stable supply chains and controllable quality for your projects.

With over a decade of foreign trade experience, we understand international standards and shipping requirements. Your orders arrive on time and meet local regulations.

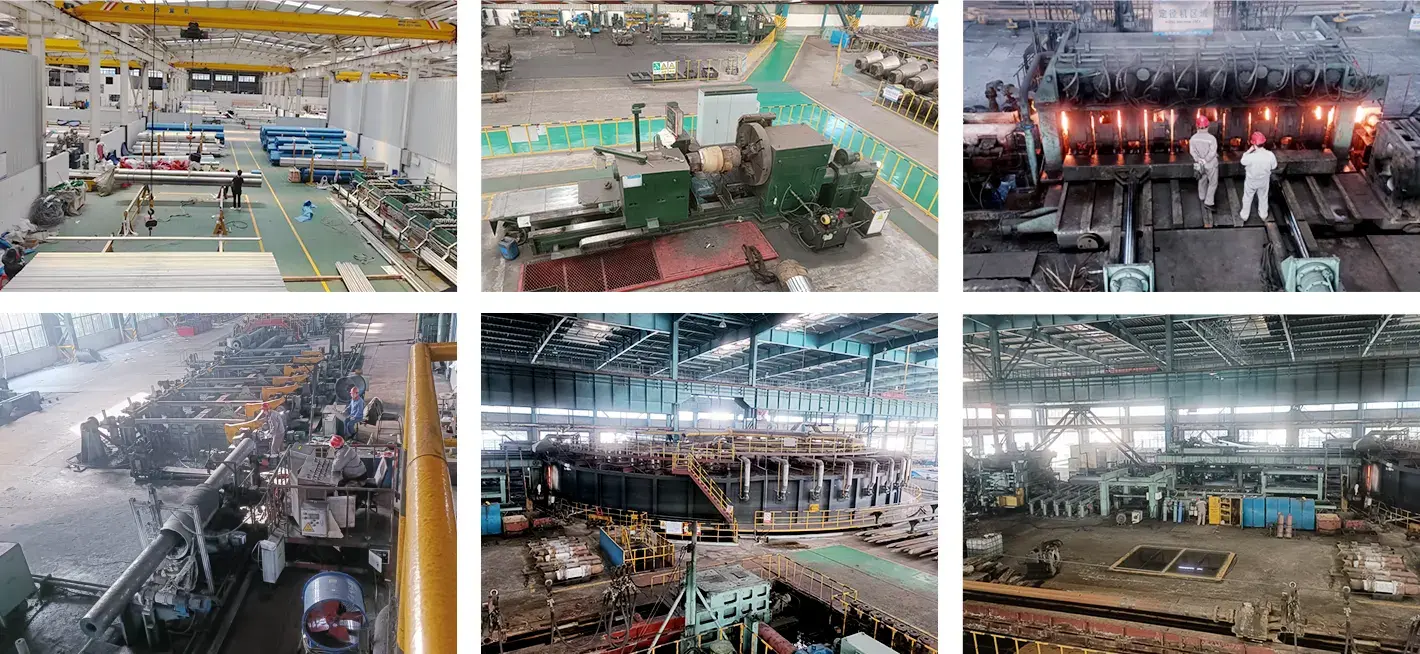

Exhibition

Complete Supply Chain Support

You benefit from our comprehensive service approach. From initial inquiry through final delivery, our experienced team handles every detail.

We offer flexible order processing and customized solutions. Your specific requirements receive prompt attention and professional responses.

Our global network spans 100+ countries. Whether you need standard specifications or custom configurations, we deliver reliable product solutions worldwide.

Ready to enhance your project with premium 15CrMoG alloy steel pipe? Contact our experienced team at admin@rongyaopipe.com for detailed specifications, competitive pricing, and professional technical support tailored to your specific requirements.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!

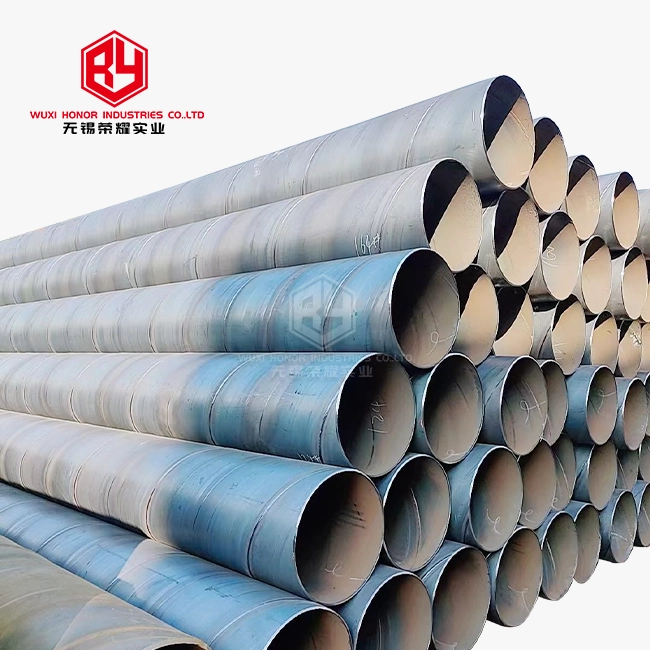

Seamless Steel Pipe.webp)