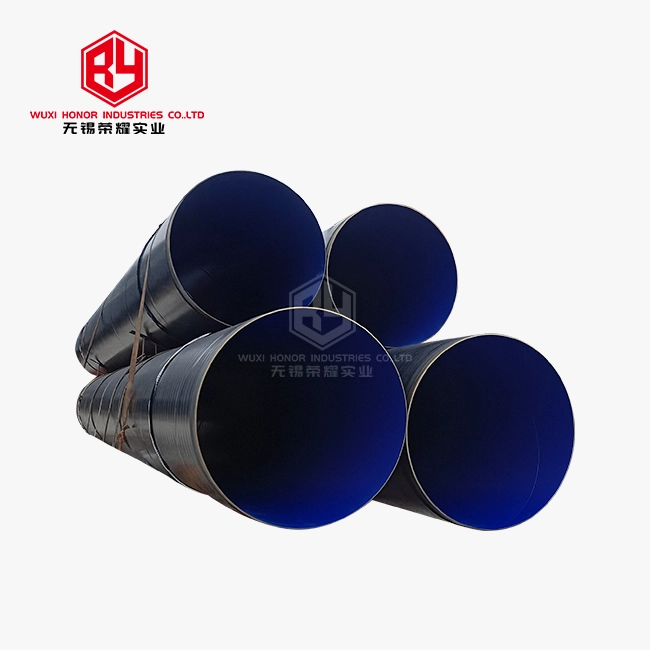

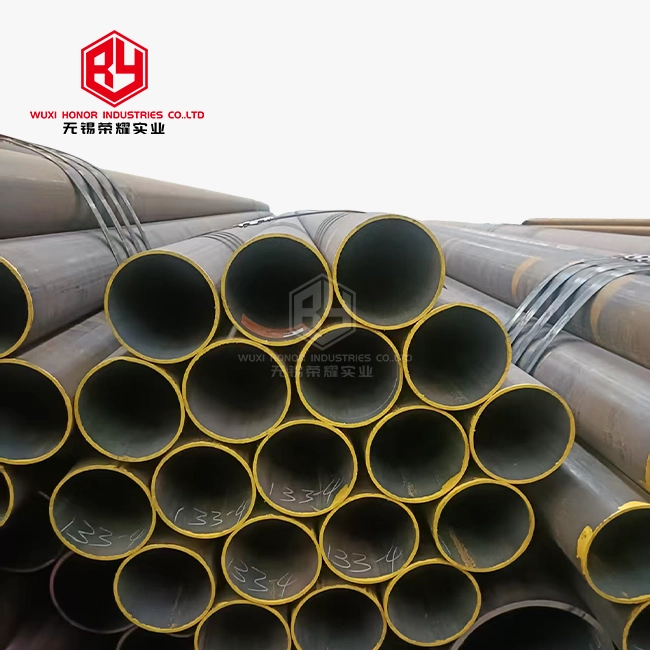

12Cr1Mov Seamless Steel Pipe

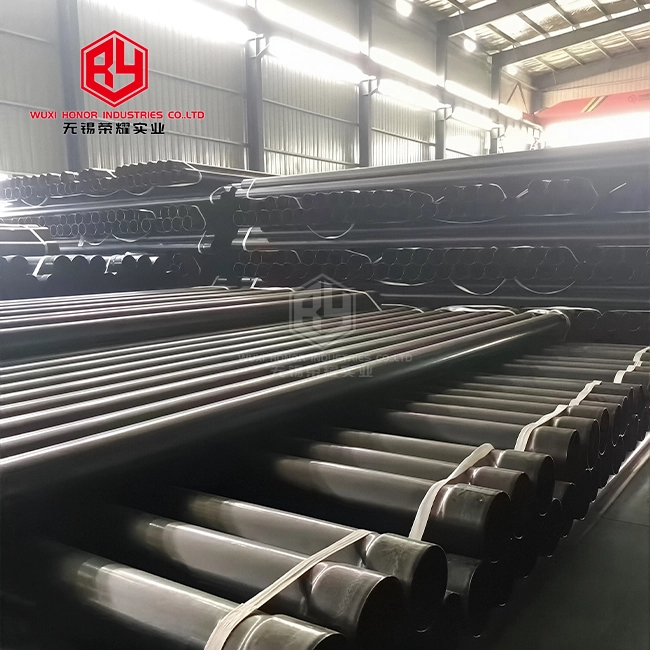

Mainly used in fields such as high-pressure boilers, petroleum cracking, shipbuilding, gas cylinders, and hydraulic equipment, its consumption accounts for about half of the total steel consumption in China compared to developed countries. The demand for high-pressure long materials is expected to grow at an average annual rate of 10-12% in the future. The steel pipe is divided into two processes: hot rolling (extrusion) and cold drawing (rolling). The hot rolling process includes steps such as heating the round billet, perforation, and continuous rolling;

The cold drawing process includes multiple processing steps such as annealing, acid washing, and copper plating. According to their purposes, they can be divided into more than ten categories, such as structural use, fluid transportation use, boiler use, etc., corresponding to different national standards (such as GB/T8162, GB5310). The mechanical performance indicators include a cross-sectional shrinkage rate of ≥ 50%, an impact absorption energy of ≥ 71J, and a Brinell hardness of ≤ 179HBS, suitable for high temperature, high pressure, and corrosive environments.

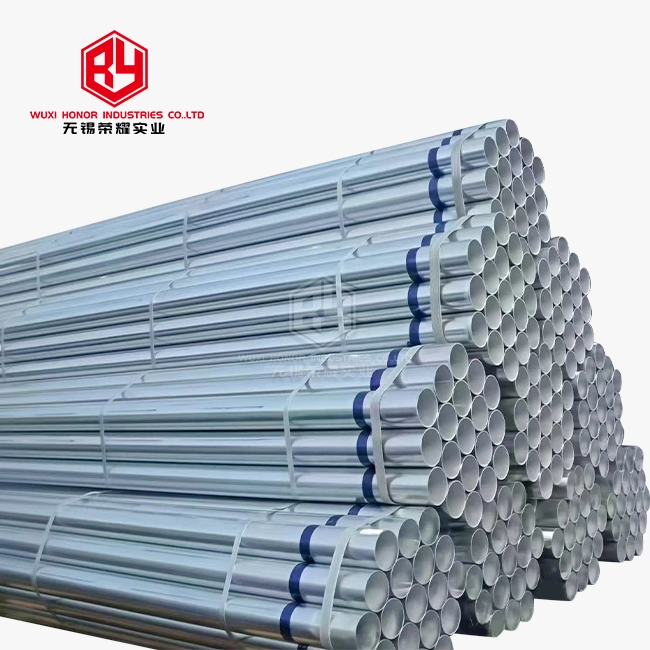

Our company's products have obtained ISO9001 certification, ensuring product quality

12Cr1MoV Seamless Steel Pipe - Premium High-Temperature Alloy Solution

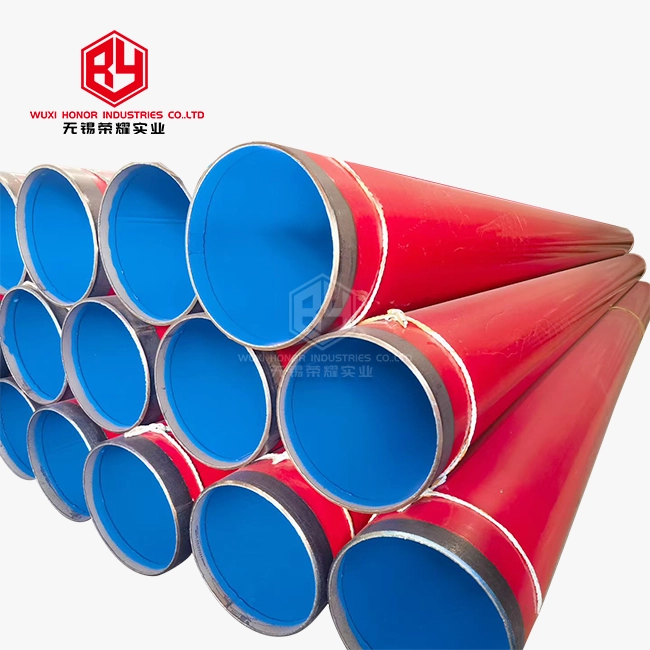

When you require dependable steel channels for high-temperature applications, 12Cr1MoV seamless steel pipe stands as your chief choice. This progressed combination basic steel fabric combines extraordinary strength with exceptional execution characteristics. Our channels provide reliable quality for requesting mechanical situations. Whether you're working with high-pressure boilers, petroleum splitting offices, or pressure driven hardware, this fabric guarantees dependable execution. The 100% recyclability makes it an ecologically mindful choice that adjusts with advanced maintainability goals.

Superior High-Temperature Performance

You'll appreciate the extraordinary warm capabilities of this combination steel pipe. The carefully optimized composition incorporates chromium, molybdenum, and vanadium increases that upgrade execution essentially. These channels work steadily in situations up to 540℃ without compromising auxiliary integrity.

The fabric stands up to oxidation and distortion indeed beneath extraordinary warm conditions. This warm solidness deciphers to longer benefit life and decreased support costs for your operations. You can number on steady execution all through amplified high-temperature introduction cycles.

Versatile Industrial Applications

Your mechanical ventures advantage from the wide extend of applications these channels bolster. High-pressure kettle frameworks depend on their strong development and warm resistance. Petroleum breaking offices select them for their chemical solidness and weight dealing with capabilities.

Shipbuilding businesses esteem their erosion resistance and auxiliary quality. Gas barrel fabricating depends on their security edges and toughness. Pressure driven hardware applications advantage from their accuracy fabricating and dependable execution characteristics.

Manufacturing Excellence and Quality Control

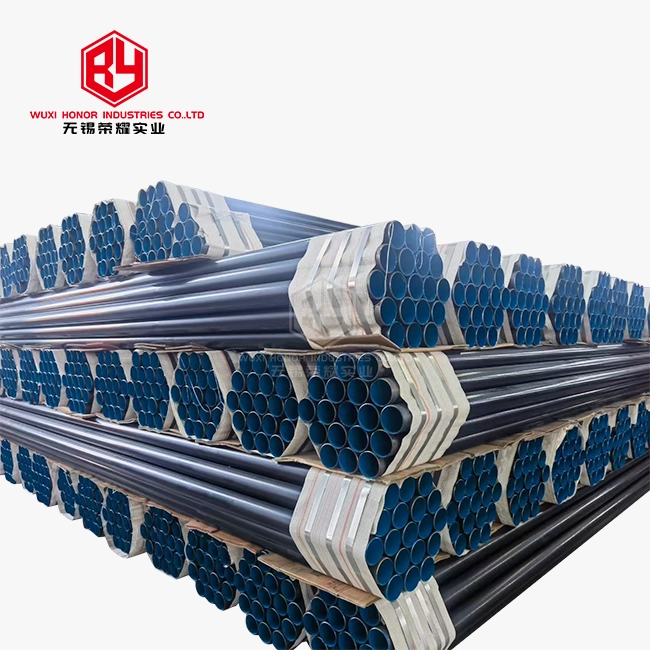

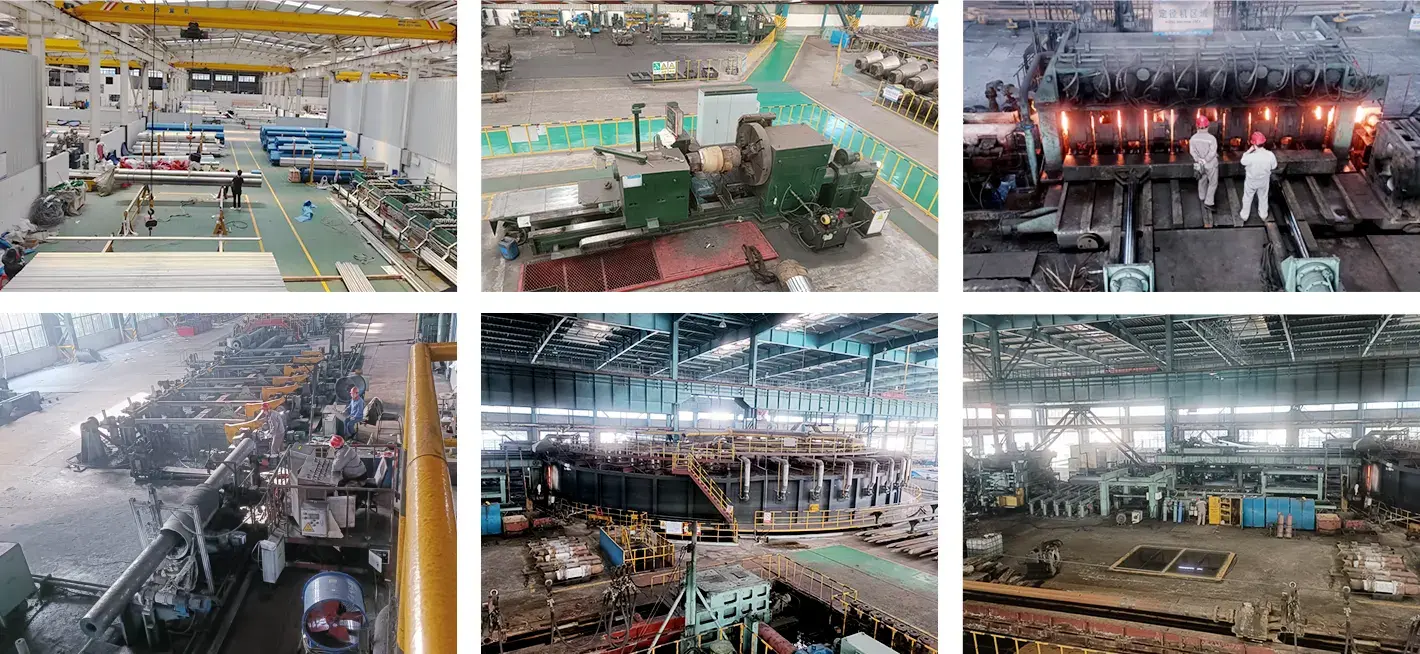

We employ both hot rolling and cold drawing processes to meet your specific requirements. The hot rolling process includes controlled heating, perforation, and continuous rolling steps. Cold drawing involves precise annealing, acid washing, and specialized surface treatments.

Our quality control measures ensure consistent mechanical properties across all products. Cross-sectional shrinkage rates maintain ≥50% standards. Impact absorption energy exceeds 71J requirements. Brinell hardness stays within optimal ≤179HBS parameters.

Technical Specifications and Standards

You receive products that comply with multiple national standards including GB/T8162 and GB5310. These certifications ensure compatibility with international project requirements. Our 12Cr1MoV seamless steel pipe meet structural use, fluid transportation, and specialized boiler application standards.

The manufacturing process guarantees uniform material properties and dimensional accuracy. Heat treatment protocols optimize the microstructure for enhanced performance. Quality traceability systems document every production step for your peace of mind.

Certificate

Proven Global Supply Capabilities

WUXI HONOR INDUSTRIES brings over ten years of specialized experience to your projects. Our supply network spans more than 100 countries worldwide, ensuring reliable delivery regardless of your location. We understand international trade requirements and customs procedures across different regions.

Our established relationships with premium steel mills guarantee consistent raw material quality. The mature supply chain management system minimizes delays and ensures predictable delivery schedules for your critical projects.

Exhibition

Environmental and Economic Benefits

The complete recyclability of this 12Cr1MoV seamless steel pipe supports your environmental sustainability goals. Resource conservation becomes achievable without compromising performance standards. The long service life reduces replacement frequency and associated costs.

Energy efficiency in high-temperature applications improves through superior thermal properties. Reduced maintenance requirements translate to lower operational expenses over the pipe's lifetime. These economic advantages make it a smart long-term investment choice.

Factory

Professional Support and Service

Our experienced team provides comprehensive technical support throughout your project lifecycle. From initial specification consultation to delivery coordination, we ensure smooth project execution. Multilingual communication capabilities facilitate clear understanding across international projects.

Flexible order processing accommodates your specific timeline requirements. Customized solutions address unique application challenges you might face. Our rapid response system keeps your projects moving forward without unnecessary delays.

Ready to enhance your high-temperature applications with premium 12Cr1MoV seamless steel pipe solutions? Contact our experienced team at admin@rongyaopipe.com for detailed specifications and competitive pricing tailored to your project requirements.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!