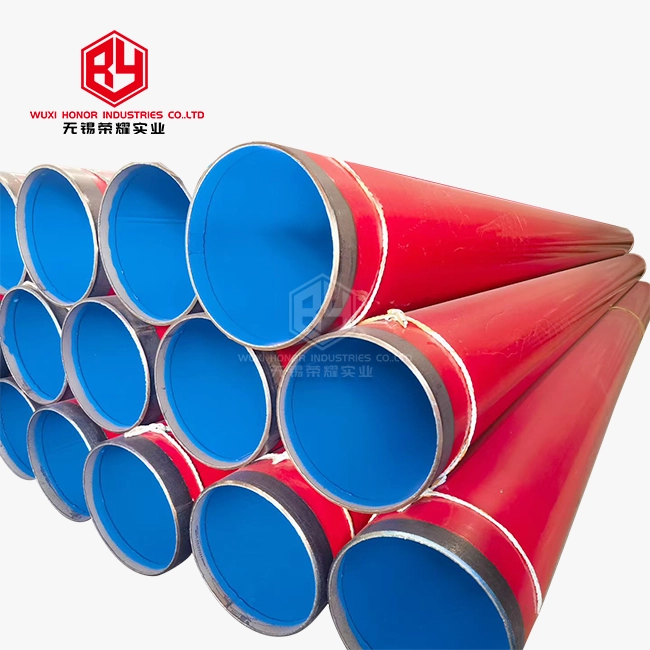

Hot Dip Plastic Threading Pipe

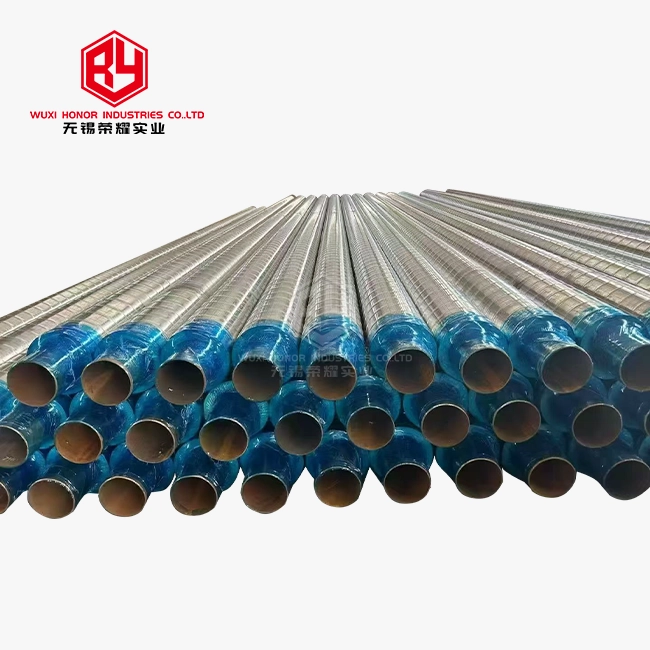

The coating adopts a new type of nano anti-corrosion material, with a uniform and smooth surface and low friction coefficient. The inner wall has no welding ribs or burrs to reduce threading resistance. The connection method adopts a socket design, combined with rubber sealing rings to prevent mud and sand from entering, and the expansion design can improve the sealing performance. The production process utilizes patented welding rib removal technology and 12 pre-treatment processes to ensure strong coating adhesion and resistance to detachment. It has high mechanical strength, both anti settlement and anti salt alkali corrosion properties, and can be used for a long time in an environment of 130 ℃.

Our company's products have obtained ISO9001 certification, ensuring product quality

Hot Dip Plastic Threading Pipe: Superior Protection for Your Cable Infrastructure

When you require solid cable assurance for requesting situations, hot dip plastic threading pipe conveys unmatched execution. This imaginative conduit fabric combines high-strength steel development with progressed polyester tar coating innovation. Accessible in details from DN15 to DN800, our threading channels give remarkable toughness and erosion resistance for broadcast communications, control designing, transportation, and urban development ventures over assorted working conditions.

What Makes Our Threading Pipes Stand Out

Advanced Coating Technology

Our channels highlight a cutting-edge nano anti-corrosion fabric coating. The surface remains uniform and smooth with an especially moo contact coefficient. This plan altogether diminishes threading resistance amid cable establishment. You'll discover no welding ribs or burrs on the internal divider, guaranteeing smooth cable pulling operations each time.

Exceptional Environmental Performance

These channels work successfully in temperatures extending from -15°C to +100°C. They withstand weight up to 1.6MPa whereas keeping up auxiliary astuteness. The coating gives extraordinary resistance to settlement and salt-alkali erosion. You can depend on long-term execution indeed in challenging situations up to 130°C.

Intelligent Connection Design

Our attachment association framework joins elastic fixing rings that avoid mud and sand invasion. The development plan upgrades fixing execution essentially. This mindful building guarantees your cable framework remains ensured from natural defilement all through its benefit life.

Superior Protection Through Innovative Engineering

Corrosion Resistance and Insulation

The thick plastic coating makes a defensive boundary against soil, dampness, acids, antacids, and salts. This comprehensive security expands distant past fundamental conduit materials. Your cables advantage from great electrical separator properties that anticipate dampness invasion and electrical spillage. This security demonstrates important in unforgiving and destructive situations where standard materials fail.

Robust Mechanical Strength

The plastic coating bonds firmly to the steel substrate, making momentous resistance to peeling and splitting. This combination conveys the tall quality of steel with plastic's predominant erosion resistance. You get exceptional affect and compressive quality that withstands development impacts and soil compression effectively.

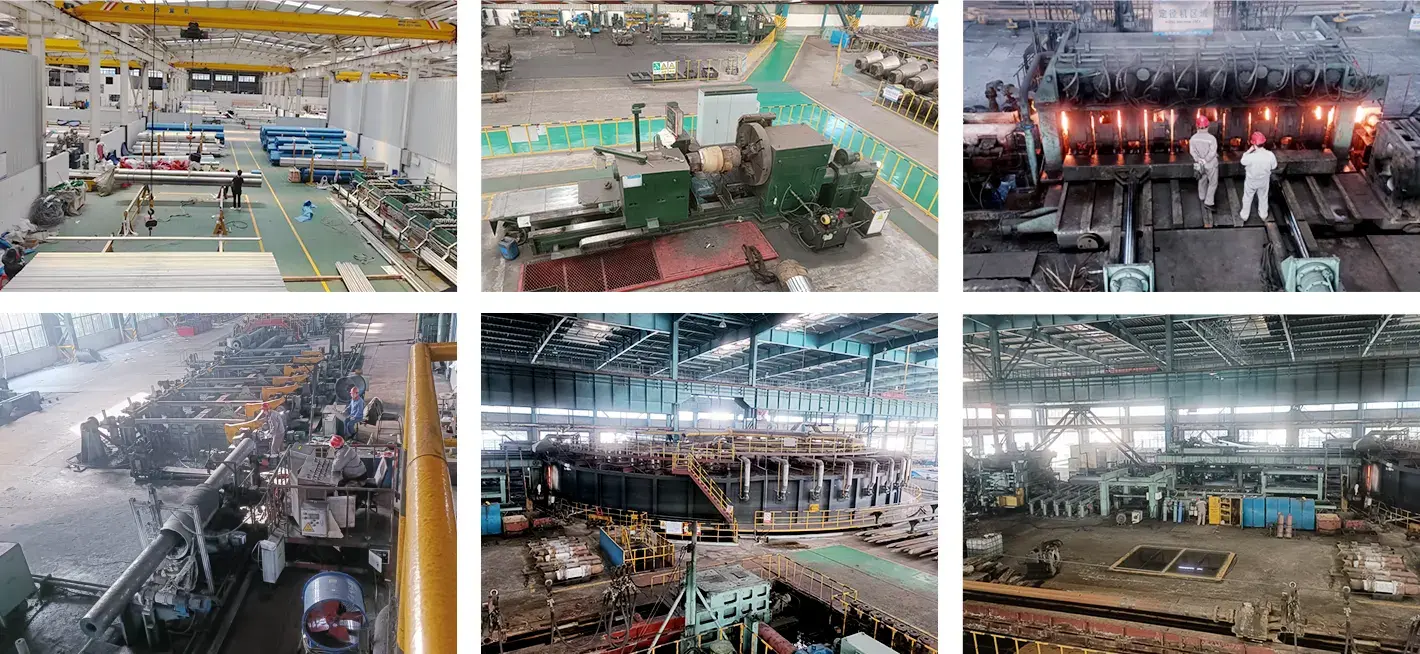

Why Choose WUXI HONOR INDUSTRIES

Over a Decade of Excellence

With more than ten a long time in metal materials and specialized channeling arrangements, we get it your framework needs. Our encounter serving clients in over 100 nations gives us special understanding into assorted venture prerequisites and natural challenges.

Comprehensive Quality Assurance

Our fabricating prepare joins 12 pre-treatment steps guaranteeing solid coating grip. We utilize protected welding rib expulsion innovation that anticipates coating separation. This fastidious consideration to detail ensures steady quality in each pipe we provide.

Global Supply Chain Expertise

Our established relationships with premium steel mills ensure stable supply and consistent quality. We understand international trade requirements, customs procedures, and logistics coordination. This expertise means your orders arrive on schedule, properly documented, and ready for immediate installation.

Applications Across Industries

Our hot dip plastic threading pipe serves diverse sectors including:

- Power transmission and distribution projects

- Telecommunications infrastructure development

- Transportation system cable protection

- Urban construction and development

- Industrial facility cable management

- Harsh environment installations

Technical Specifications at a Glance

- Size Range: DN15 to DN800

- Operating Temperature: -15°C to +100°C

- Pressure Rating: 1.6MPa

- Coating: Nano anti-corrosion material

- Connection Type: Socket design with rubber seals

- Certification: ISO9001 quality management

Your Partner for Reliable Infrastructure

Whether you're planning a major telecommunications rollout or upgrading power distribution systems, our threading pipes provide the protection your cables deserve. The combination of steel strength and advanced polymer coating ensures decades of reliable service.

Ready to enhance your cable protection strategy? Contact us at admin@rongyaopipe.com for detailed specifications and pricing information. Let our expertise help you select the perfect hot dip plastic threading pipe solution for your next project.

Exhibition

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!

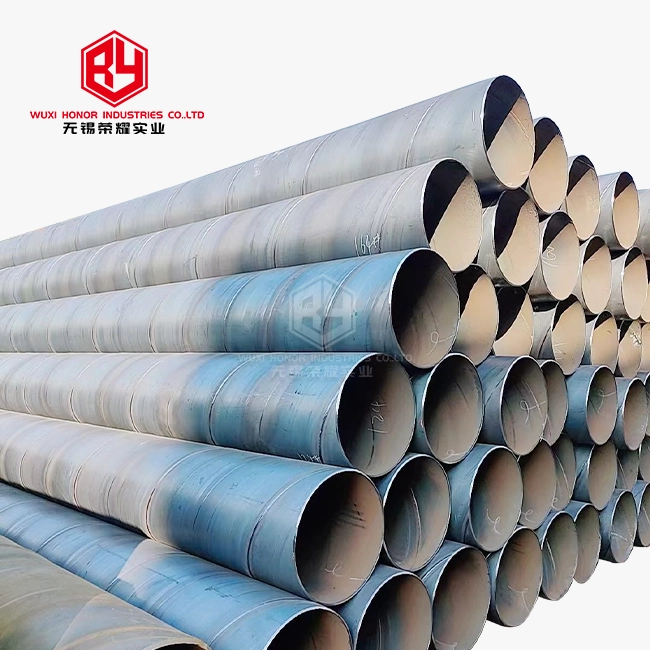

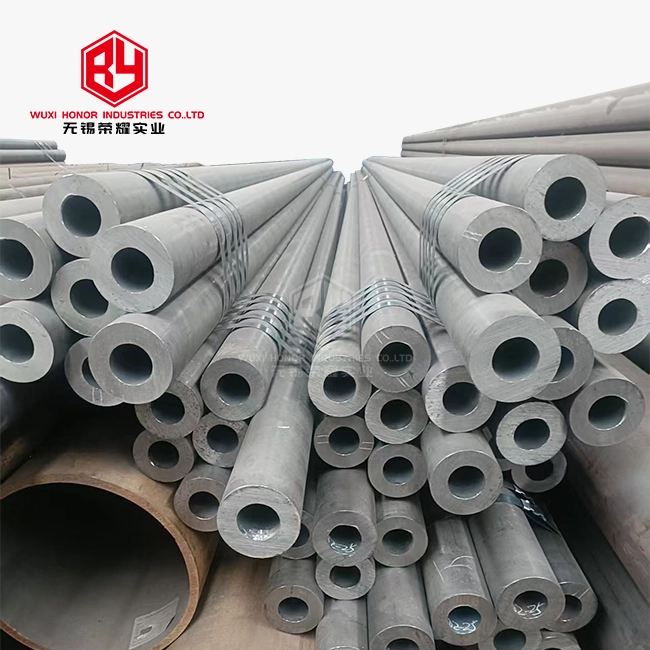

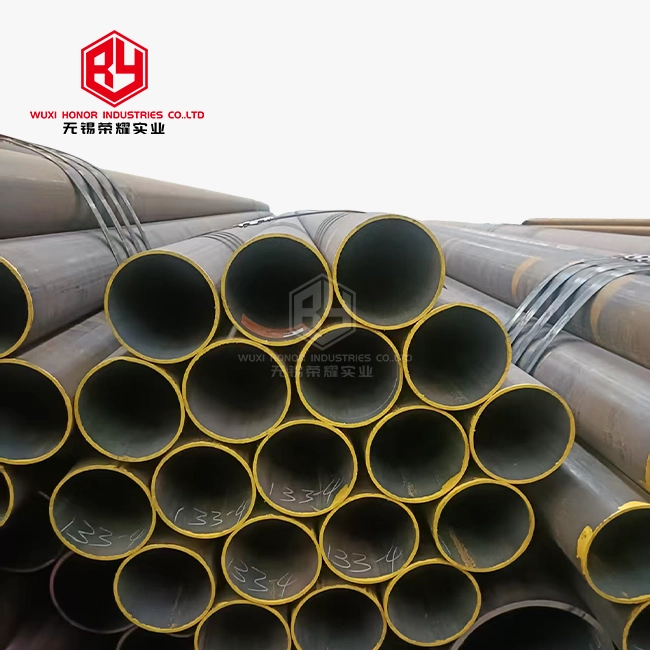

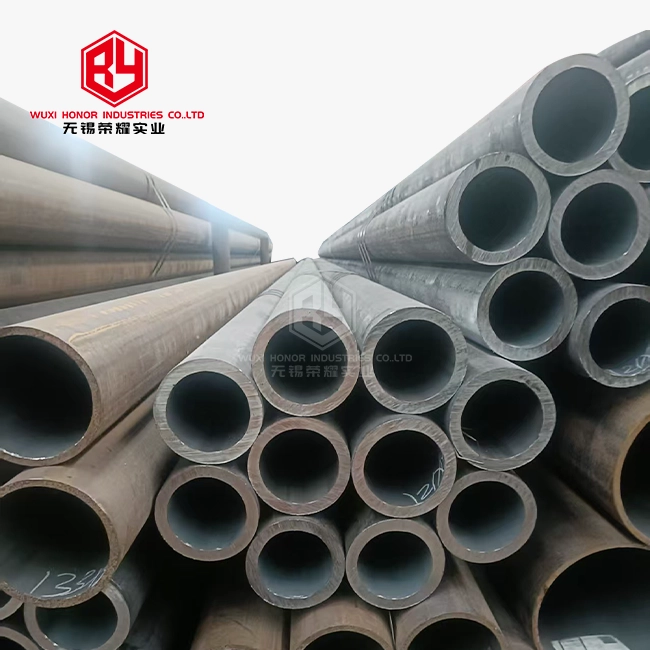

Seamless Steel Pipe.webp)