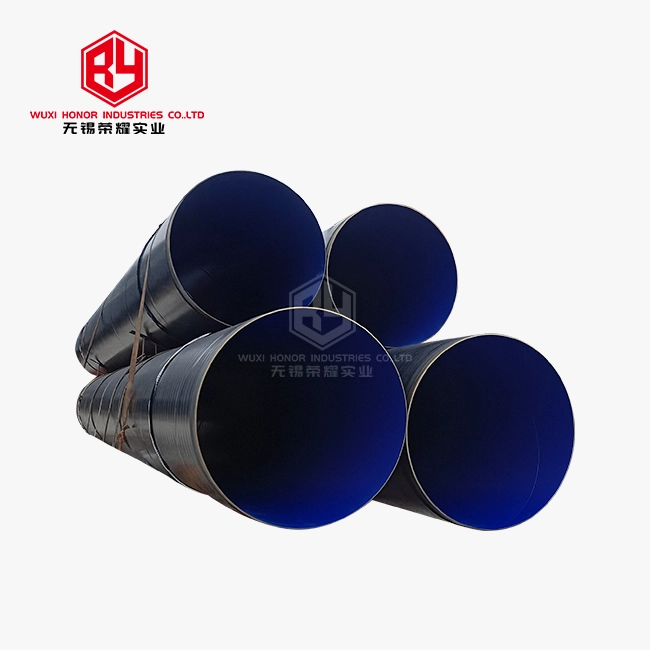

Spiral Welded Pipe

The specifications are expressed as outer diameter * wall thickness, and the welded pipe should ensure that the hydrostatic test, tensile strength, and cold bending performance of the weld meet the requirements. The commonly used materials for spiral steel pipes are: Q235A,Q235C、Q235B、16Mn、20#、Q345、L245、L290、X42、X46、X60、X80、0Cr13、1Cr17、00Cr19Ni11、1Cr18Ni9、0Cr18Ni11Nb Wait

Our company's products have obtained ISO9001 certification, ensuring product quality

High-Quality Spiral Welded Pipe for Industrial Applications

Looking for dependable pipeline arrangements for your mechanical ventures? Our spiral welded pipe offers uncommon execution for large-diameter applications over different businesses. Made by rolling low-carbon or low-alloy basic steel strips at exact winding points, these channels provide predominant auxiliary astuteness and weight resistance. With over ten a long time of ability in metal materials, WUXI HONOR Businesses gives trusted arrangements to clients in more than 100 nations worldwide.

What Makes Our Spiral Welded Pipes Stand Out

Superior Structural Design

Our channels include interesting winding weld creases that disperse push equally over the whole structure. This plan makes way better generally astuteness compared to conventional straight-seam choices. The winding arrangement gives improved affect resistance and distortion control, making these channels perfect for requesting applications.

Exceptional Pressure Resistance

Each pipe experiences thorough hydrostatic testing to guarantee solid execution beneath weight. The winding welding handle makes more grounded joints that can handle medium to high-pressure liquid transportation securely. Your ventures advantage from steady execution and long-term durability.

Flexible Specifications

We offer customizable measurements communicated as external breadth × divider thickness. Our fabricating prepare permits generation of large-diameter channels utilizing smaller steel strips, optimizing fabric utilization whereas assembly your particular prerequisites. This adaptability makes us your perfect accomplice for differing extend needs.

Premium Materials and Quality Standards

Comprehensive Material Options

Our spiral welded pipe products utilize high-grade materials including:

- Q235A, Q235B, Q235C for standard applications

- 16Mn, 20#, Q345 for enhanced strength requirements

- L245, L290, X42, X46, X60, X80 for pipeline applications

- Stainless steel grades: 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb

Guaranteed Quality Assurance

All our products meet ISO9001 certification standards, ensuring consistent quality you can trust. We maintain strict quality control processes with complete product traceability. Every pipe meets international standards for tensile strength, cold bending performance, and weld integrity.

Applications and Industries

Industrial Manufacturing

Perfect for machinery manufacturing and petrochemical facilities requiring reliable fluid transportation systems. The high pressure resistance makes these pipes suitable for various industrial processes.

Construction and Infrastructure

Large-diameter capabilities make our pipes ideal for building projects and infrastructure development. The structural strength supports demanding construction requirements while maintaining cost-effectiveness.

Pipeline Projects

Excellent choice for medium and high-pressure pipeline installations. The spiral design provides superior performance in long-distance transportation systems.

Why Choose WUXI HONOR INDUSTRIES

Global Experience and Reach

With over a decade in international trade, we understand diverse market requirements across 100+ countries. Our multilingual team provides seamless communication and efficient service delivery.

Comprehensive Product Range

Beyond spiral welded pipe, we offer complete metal material solutions including carbon steel, stainless steel, copper, and aluminum products. This one-stop capability simplifies your procurement process.

Efficient Service Delivery

Our develop remote exchange framework guarantees smooth preparing from request to conveyance. We handle traditions strategies, coordinations coordination, and give end-to-end back for your projects.

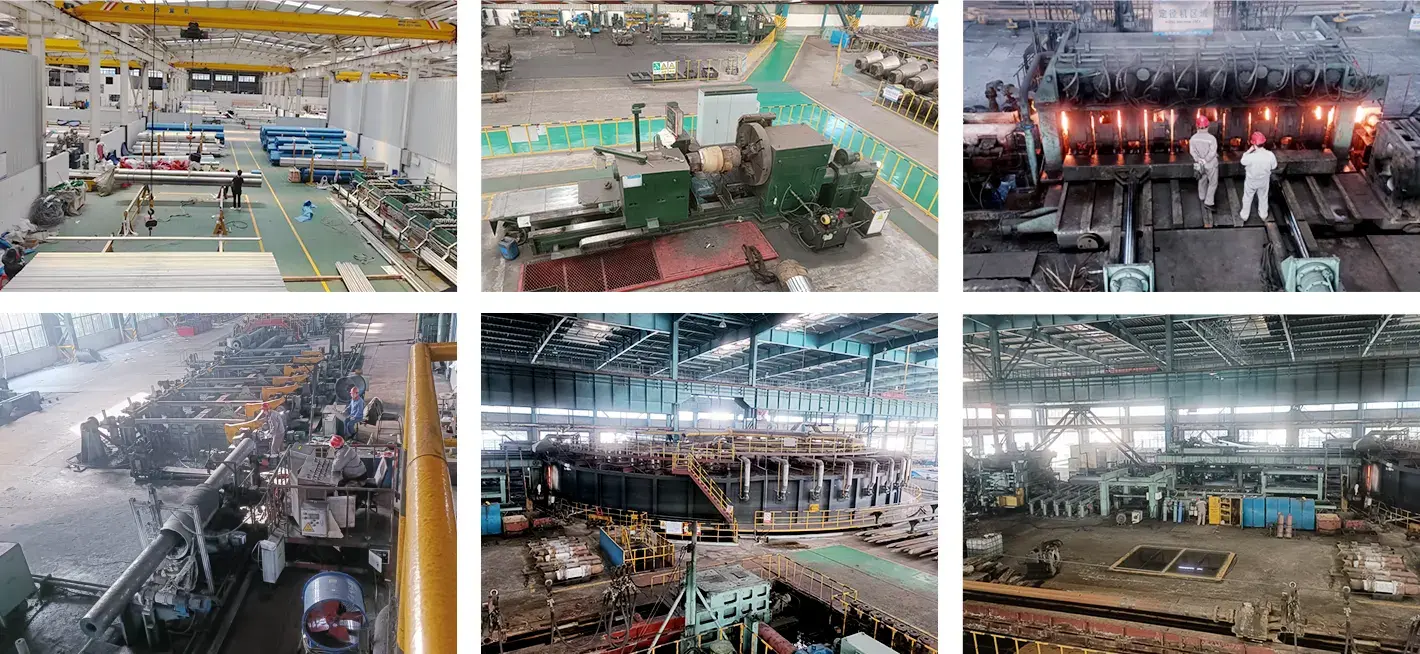

Stable Supply Chain

Long-term organizations with quality steel plants ensure reliable supply and controlled quality. Our built up upstream connections guarantee dependable conveyance plans for your projects.

Technical Specifications and Customization

We give nitty gritty specialized determinations custom-made to your venture prerequisites. Our building group works closely with you to decide ideal measurements, fabric grades, and execution characteristics.

Quality testing incorporates hydrostatic weight tests, malleable quality confirmation, and cold bowing execution assessment. Each Winding Welded Pipe meets rigid worldwide benchmarks some time recently shipment.

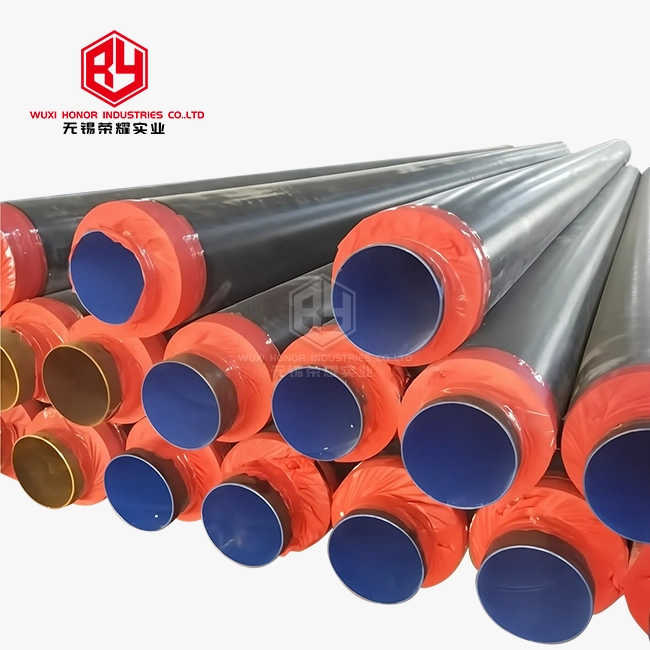

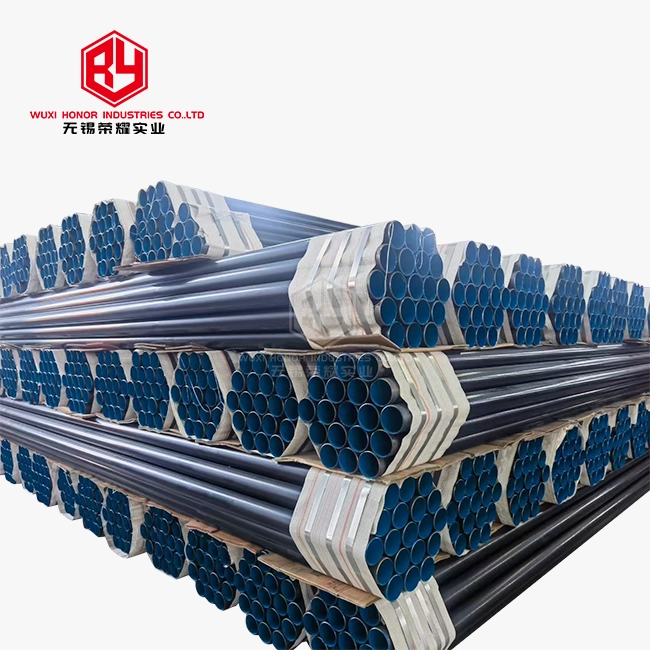

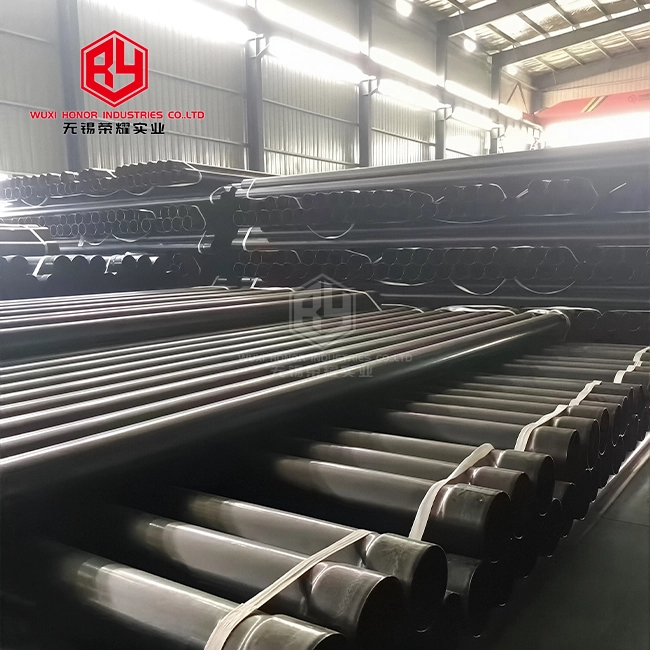

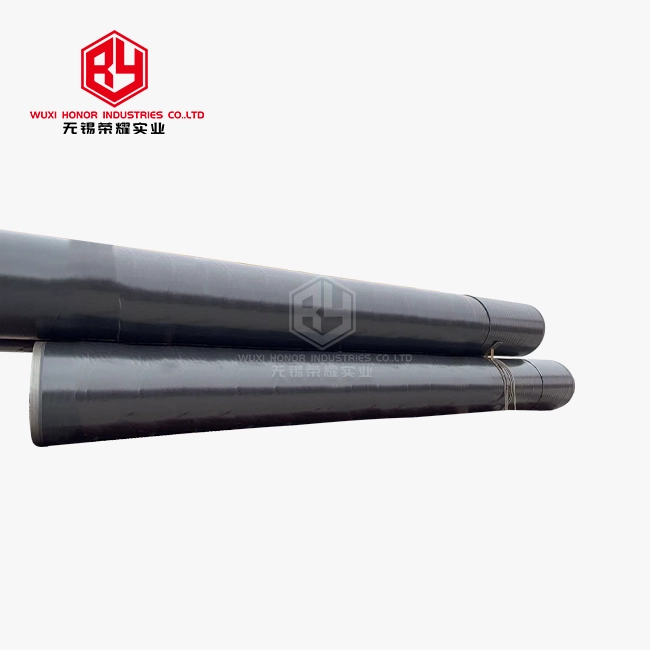

Exhibition

Get Your Quote Today

Ready to enhance your project with premium spiral welded pipe? Our experienced team stands ready to provide customized solutions for your specific needs. Contact us at admin@rongyaopipe.com for detailed quotations and technical specifications.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!