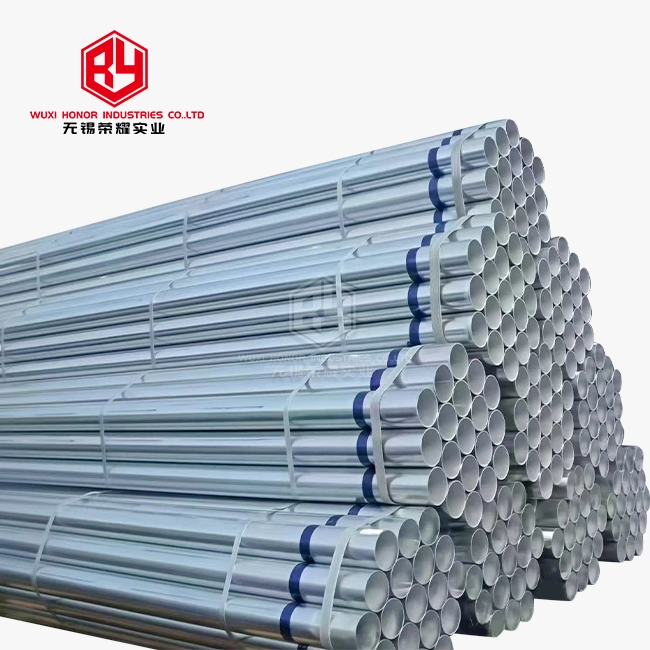

Plastic Coated Steel Pipe

Coated steel pipes have excellent corrosion resistance and relatively low friction resistance. Epoxy resin coated steel pipes are suitable for transporting media such as water supply and drainage, seawater, warm water, oil, and gas, while polyvinyl chloride coated steel pipes are suitable for transporting media such as drainage, seawater, oil, and gas.

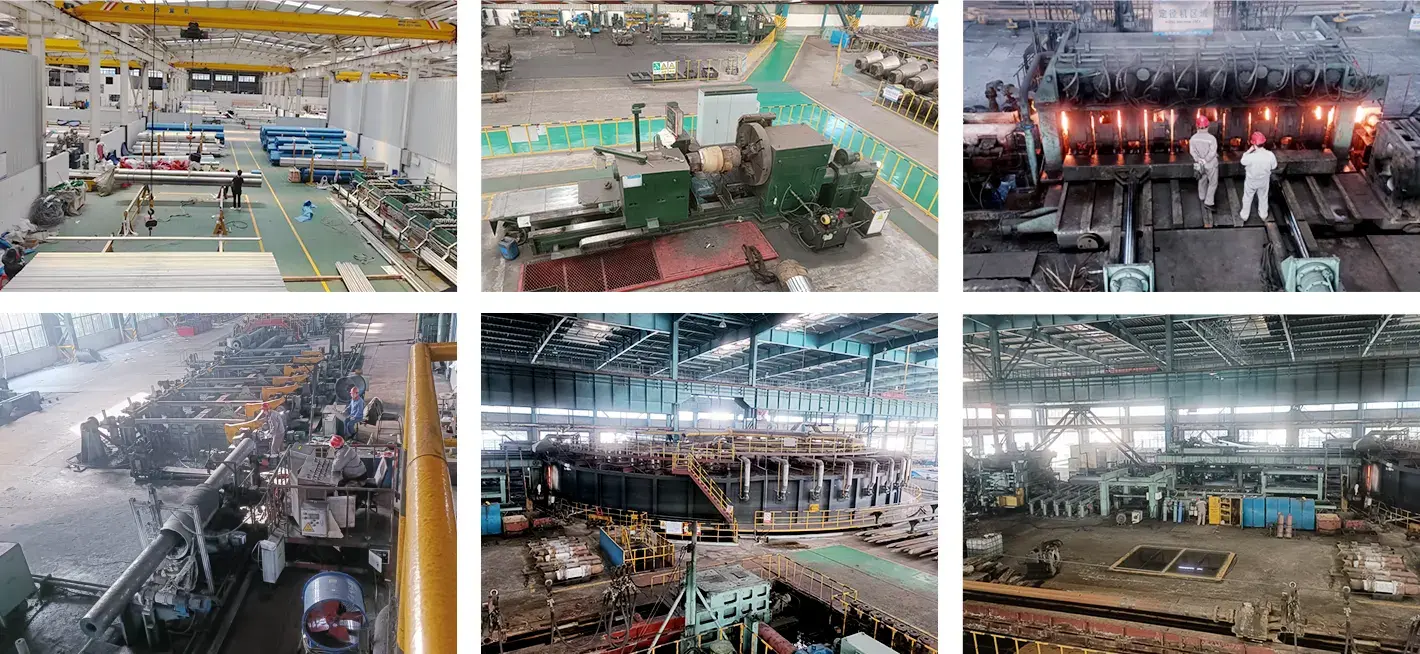

Our company's products have obtained ISO9001 certification, ensuring product quality

Plastic Coated Steel Pipe - Superior Protection for Industrial Applications

When you require solid channeling arrangements that combine quality with erosion resistance, plastic coated steel pipe offers the idealize adjust of strength and assurance. These inventive composite channels highlight steel substrates with plastic anti-corrosion layers connected through progressed splashing, rolling, or inundation forms. You get the auxiliary judgment of steel combined with the chemical resistance of plastic coatings. This makes them perfect for challenging mechanical situations where standard channels might fall flat. Our ISO9001-certified fabricating guarantees steady quality you can believe for your basic applications.

What Makes Coated Steel Pipes Special

Steel plastic composite channels provide extraordinary execution through their one of a kind dual-layer development. The steel center gives mechanical quality and weight resistance. In the mean time, the plastic coating acts as a defensive obstruction against natural damage.

You'll discover these channels exceed expectations in applications requiring both auxiliary judgment and chemical resistance. The coating materials ordinarily incorporate polyethylene, epoxy tar, or polyvinyl chloride, each chosen for particular application requirements.

Key Benefits for Your Projects

Superior Corrosion Protection

The plastic coating separates your channels from destructive components like soil dampness, acids, soluble bases, and salts. This assurance amplifies pipe life essentially compared to uncoated options. You'll involvement less support issues and diminished substitution costs over time.

Enhanced Flow Characteristics

Smooth insides coatings decrease contact misfortune amid liquid transportation. This implies way better vitality productivity and moved forward framework execution. Your pumping costs diminish whereas stream rates increase.

Versatile Application Range

Plastic coated steel pipe frameworks handle different media counting water supply, waste, seawater, oil, and gas transportation. The coating sort decides particular media compatibility, guaranteeing ideal execution for your application.

Construction and Installation Advantages

These composite channels offer helpful establishment alternatives. You can utilize conventional welding strategies or rib associations depending on your venture necessities. The channels stand up to misshapening and handle affect well amid installation.

The coating remains adaptable sufficient to oblige warm development whereas keeping up defensive judgment. This adaptability anticipates breaking or partition that may compromise performance.

Quality and Performance Standards

Our fabricating forms meet strict universal guidelines. The ISO9001 certification illustrates our commitment to steady quality control. Each pipe experiences careful testing to confirm coating grip and thickness.

The anti-aging properties of modern coatings ensure long-term performance. You'll see minimal degradation even after years of service in demanding conditions.

Material Options and Specifications

Different coating materials serve specific applications:

Epoxy resin coatings work excellently for water supply systems, warm water applications, and general industrial use. They provide excellent adhesion and chemical resistance.

Polyvinyl chloride coatings excel in drainage applications and environments with specific chemical exposures. They offer good flexibility and impact resistance.

Polyethylene coatings provide outstanding chemical resistance and work well in buried applications where soil contact is unavoidable.

Applications Across Industries

These versatile pipes serve multiple industries effectively. Municipal water systems benefit from their corrosion resistance and smooth flow characteristics. Oil and gas operations use them for gathering lines and distribution systems.

Industrial facilities choose coated pipes for process lines handling corrosive chemicals. The plastic coated steel pipe construction prevents contamination while maintaining system pressure ratings.

Marine applications particularly benefit from the saltwater resistance these coatings provide. Offshore platforms and coastal facilities rely on this protection.

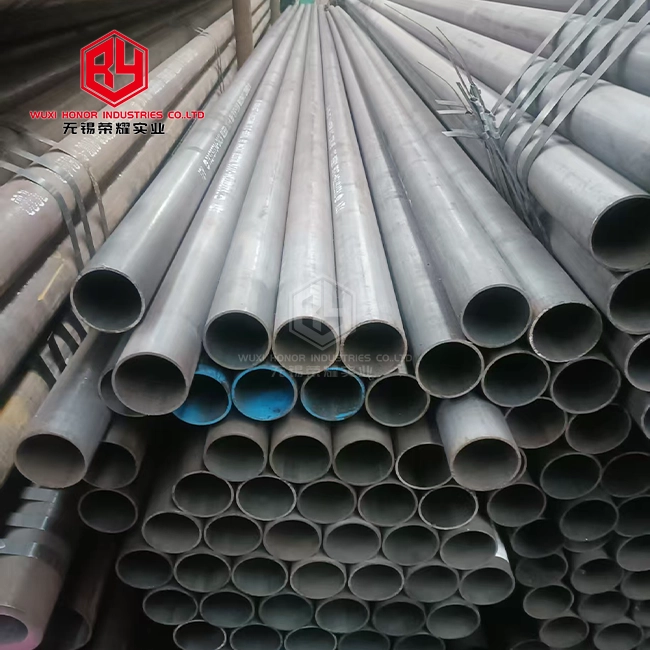

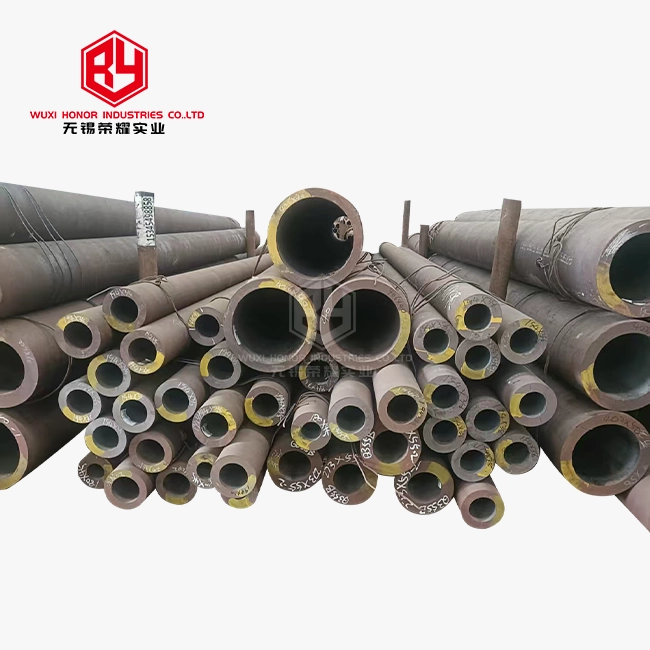

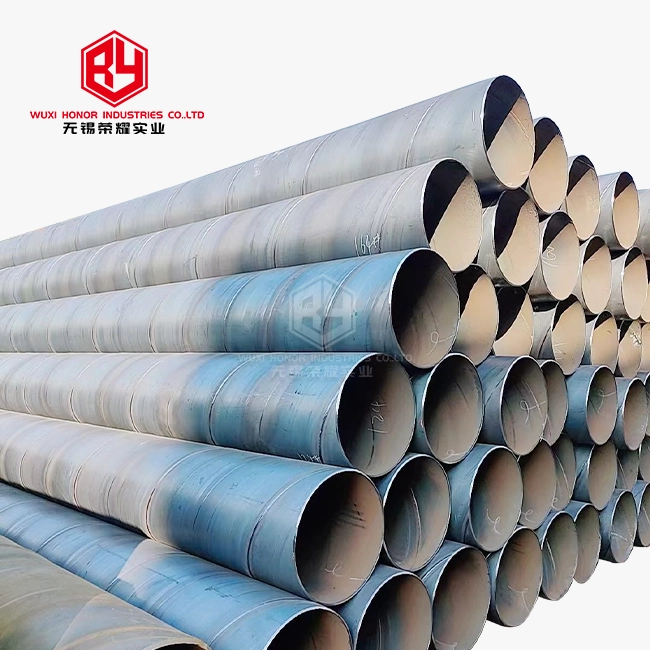

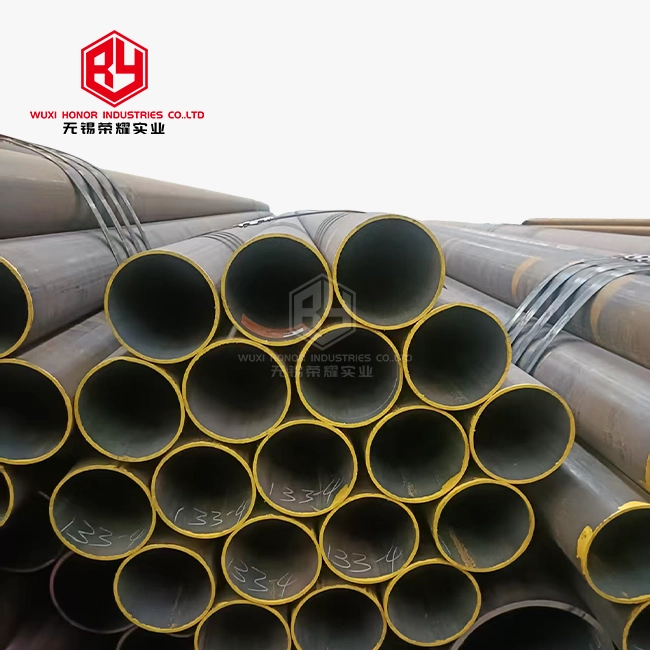

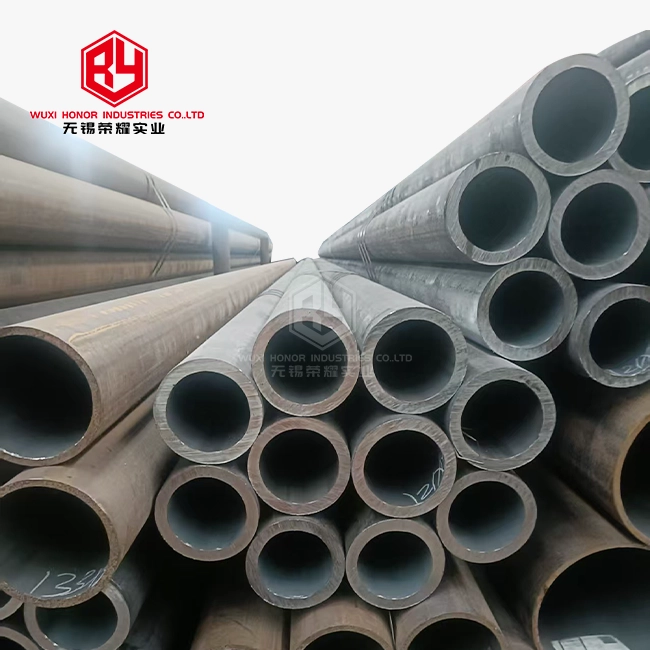

Exhibition

Why Choose WUXI HONOR INDUSTRIES

Our decade of experience in metal materials gives you access to proven expertise. We serve customers in over 100 countries, understanding diverse application requirements and local standards.

Our global supply network ensures reliable delivery schedules. You'll work with suppliers who understand international logistics and customs procedures.

We maintain partnerships with quality steel mills worldwide. This gives you access to consistent raw materials and competitive pricing.

Technical Support and Service

Our experienced team provides technical guidance throughout your project. We help you select appropriate coating types and specifications for your specific applications.

From initial inquiry through delivery, you'll receive comprehensive support. Our proven foreign trade experience ensures smooth international transactions.

Ready to explore how plastic coated steel pipe solutions can improve your next project? Contact our team at admin@rongyaopipe.com for detailed specifications and pricing information tailored to your requirements.

Ready to get started? Send us an inquiry, and our team will assist you promptly with all your needs!

Seamless Steel Pipe.webp)